Filter by Keywords

10 Production Schedule Templates for Production Planning

Praburam Srinivasan

Growth Marketing Manager

February 13, 2024

If you’re in the business of making something—a new app, a website, or even a multimedia project—you need to carefully plan, control, and execute your production to succeed. A good production schedule helps you to deliver your goods on time while optimizing your resources.

These blueprint plans keep everyone in the know and on track throughout every stage of the production process. These schedules specify who is responsible for each task, the completion date, and the next steps in the process .

In this guide, we’ll cover the benefits of a well-designed schedule and share 10 production schedule templates you can start using now. 🦄

What is a Production Planning Template?

Benefits of using a master production schedule template, what makes a good production planning template, 1. clickup production tracking template, 2. clickup production cost analysis template, 3. clickup daily production report template, 4. clickup manufacturing project plan template, 5. clickup manufacturing communication plan template, 6. clickup sprint planning template, 7. clickup development schedule template, 8. clickup build plan template, 9. clickup release planning template, 10. excel production schedule template by simple sheets.

A production planning template is a framework that creates a visual representation of production scheduling. The schedule establishes a production process and assigns a plan and budget, outlining the task sequence, timing, and allocation of necessary resources to create something or deliver services.

Production schedules usually include details on the production status, such as task description, start and end dates, role and responsibility assignments, and required materials for each step.

These resources are handy for optimizing workflows and minimizing obstacles that could delay production. They help project managers ensure on-time and on-budget delivery of goods and services.

A well-planned production schedule assists businesses in making intelligent, well-informed decisions and planning more efficiently.

Using a production schedule template improves your business’s efficiency and organization while contributing to the overall success of the production process. Some of the key advantages of using a production planning template include:

- More efficient resource allocation : A good production plan will help you allocate resources efficiently, including workforce, equipment, and materials. This helps reduce production costs and improve profitability

- Better time management : Production schedule templates help you create clear, reasonable timelines for each task, giving teams actionable deadlines and avoiding burnout or bottlenecks. You’ll also avoid unnecessary downtime

- Standardized processes : A production plan creates a framework for your operations and provides a consistent and replicable production process. This enhances quality control and reduces potential errors in production

- More transparency with accountability : Production schedules allow you to assign roles and responsibilities for each task, making it clear who’s responsible for each step. This makes the process transparent and holds team members accountable for their contributions

Some templates also allow you to run “what-if” scenarios. This helps you plan for different production scenarios and see how your team could overcome potential challenges. It’s a great way to build flexibility into your production schedule and keep things running smoothly, even when the unexpected happens.

A good production planning template helps make your production more efficient, flexible, and cost-efficient. The template must have an organized, logical layout and be easy to use, edit, and update.

Users need to identify tasks, timelines, and resources at a glance. Suitable templates should also have space for additional information, such as task descriptions and start and end dates. Production planning templates also benefit from built-in communication aids, including notes and comments sections, which promote collaboration within the team.

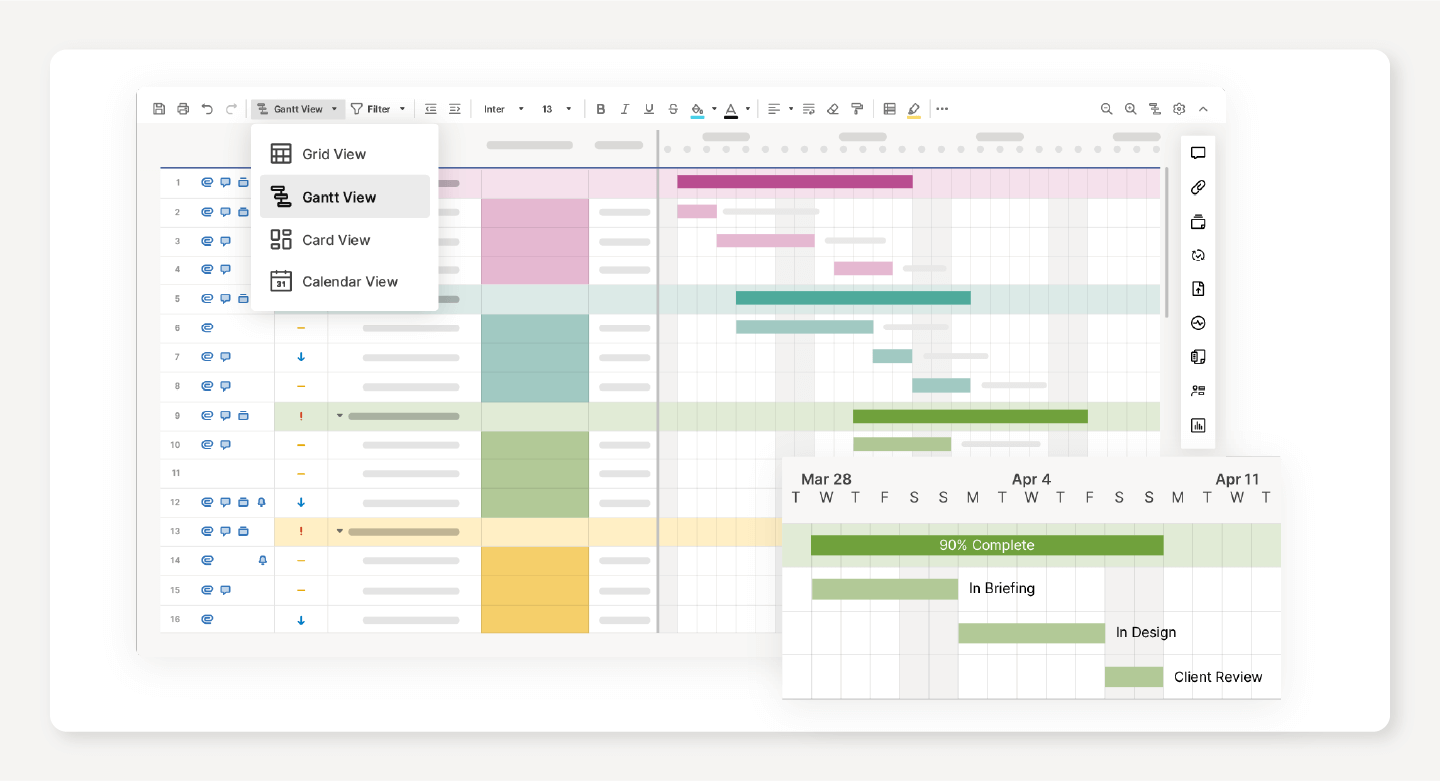

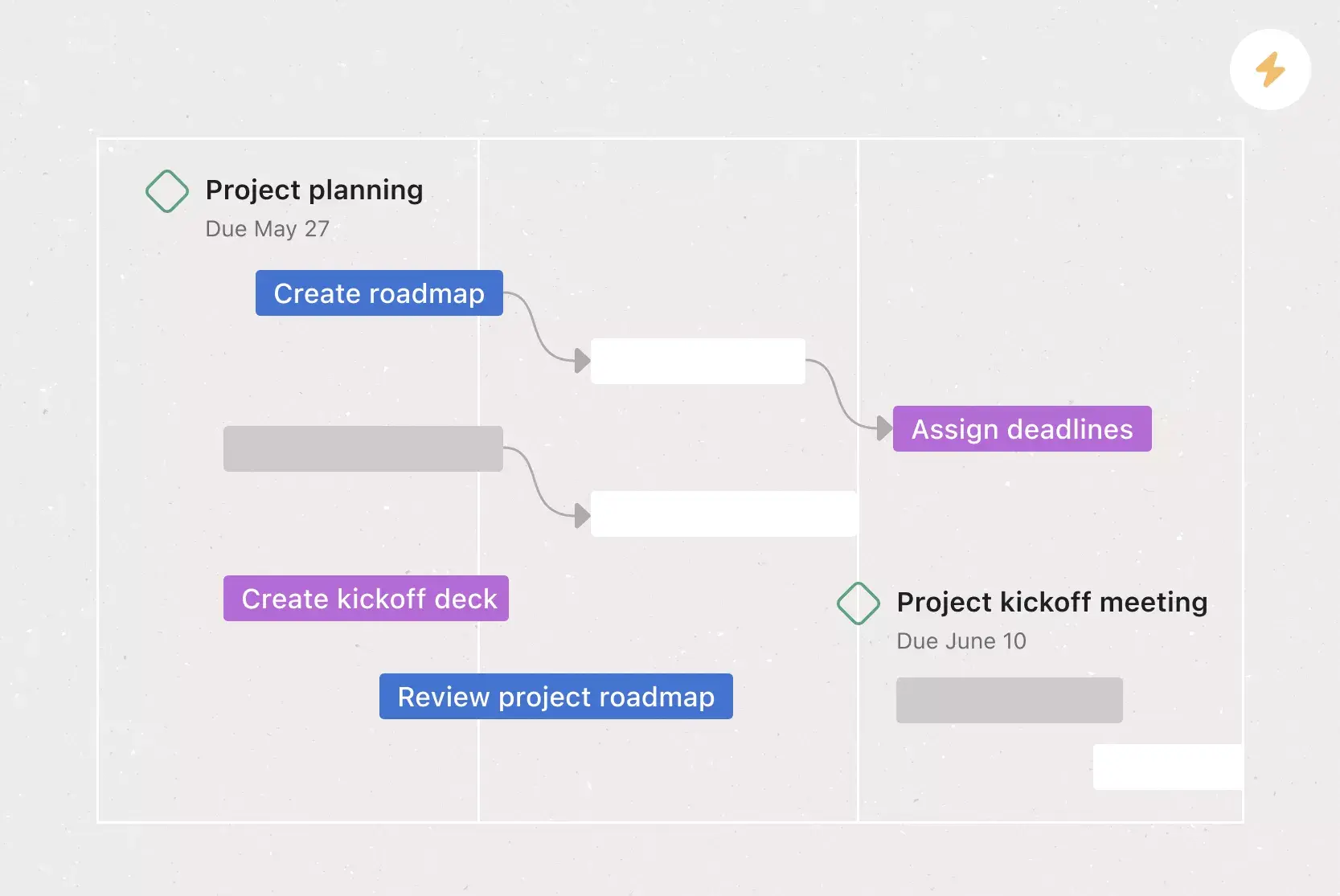

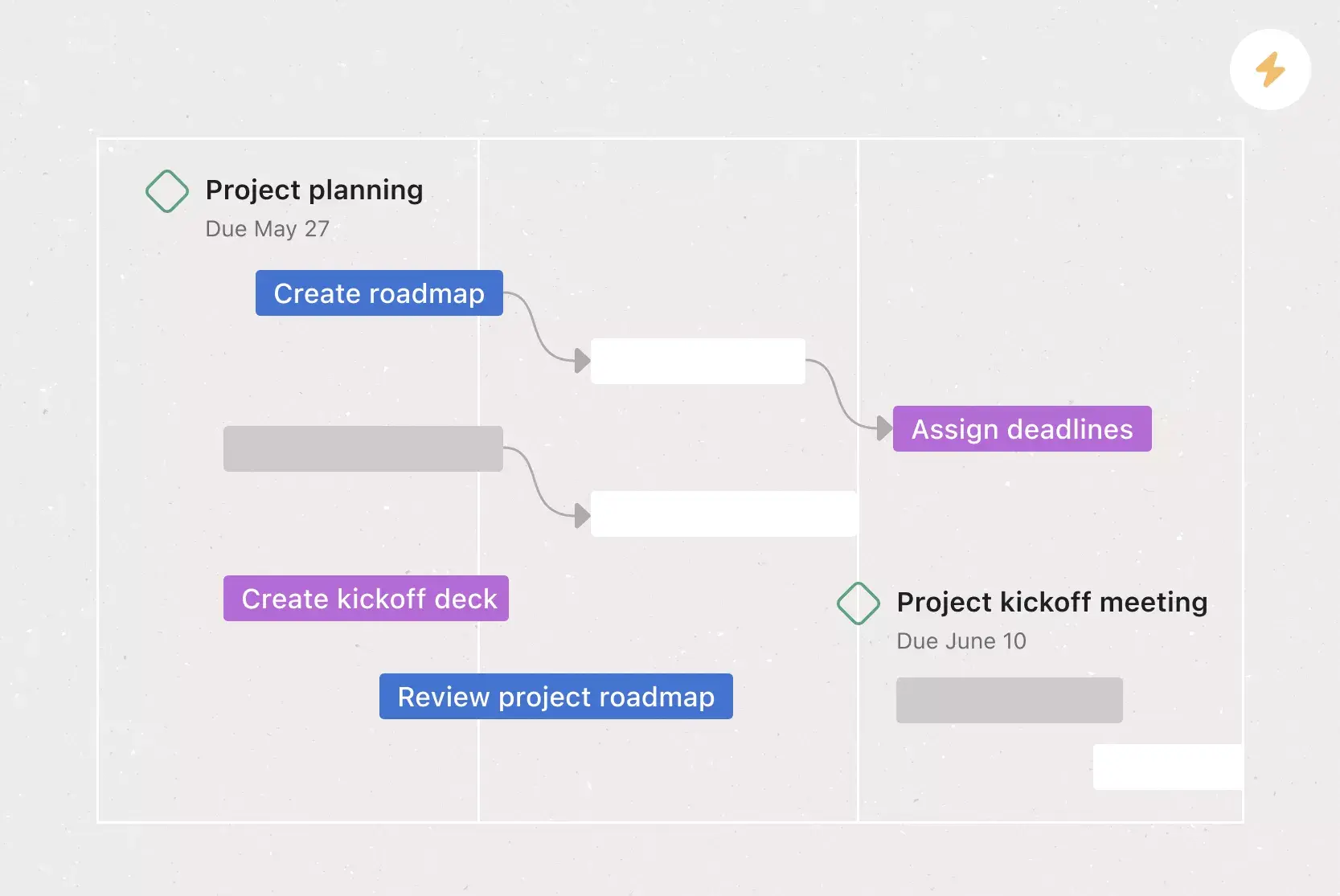

Excellent production schedule templates offer dependency indications for a smooth workflow and guide resource allocation. They typically incorporate visual elements, such as Gantt charts and milestone trackers, to mark progress within the project.

The best production planning templates are the ones that help you coordinate production tasks, minimize waste, and propel you to better on-time delivery. Experiment with several templates to see what works best for your team.

10 Production Planning Schedule Templates to Use in 2024

Here are 10 versatile and efficient production planning templates to try this year.

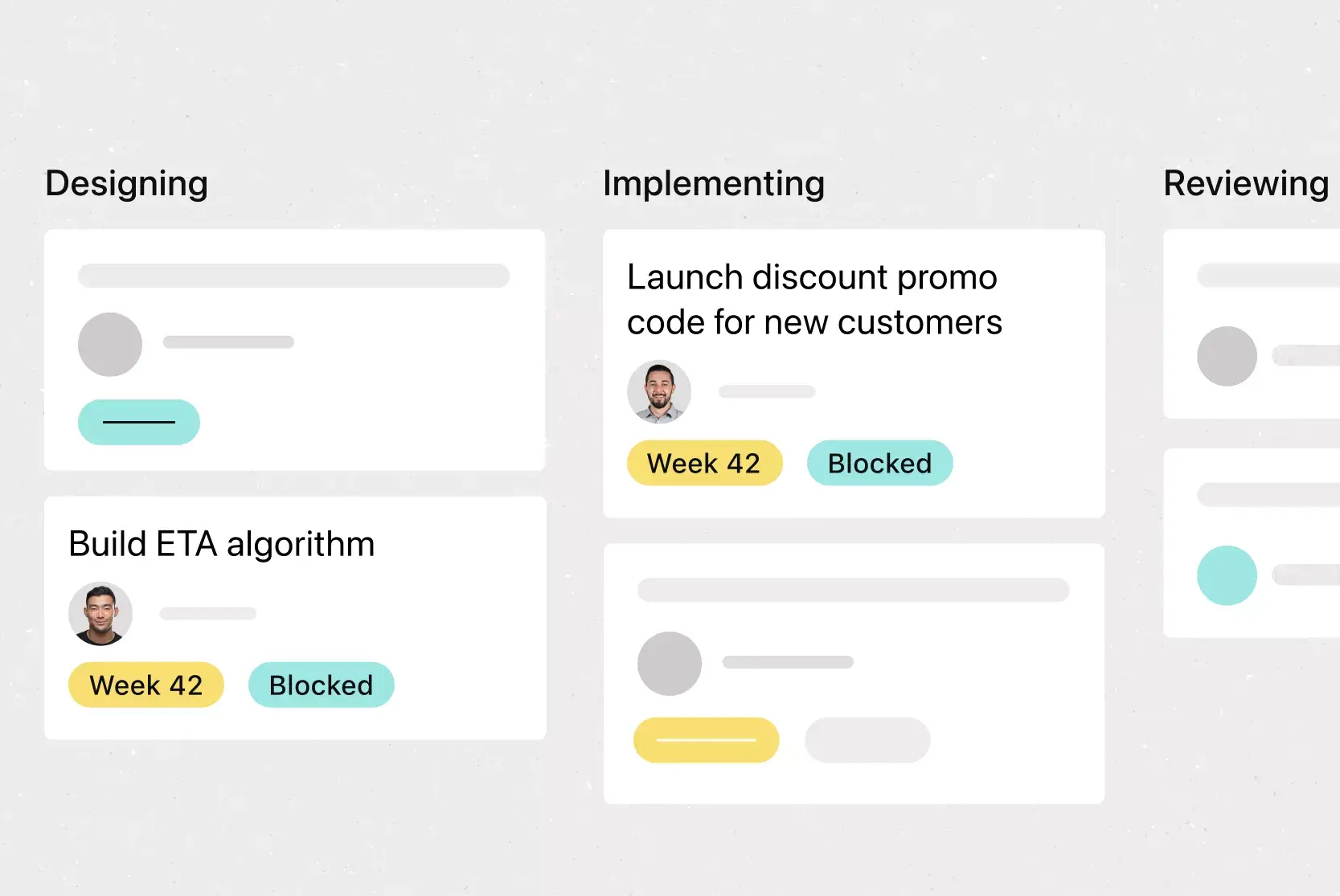

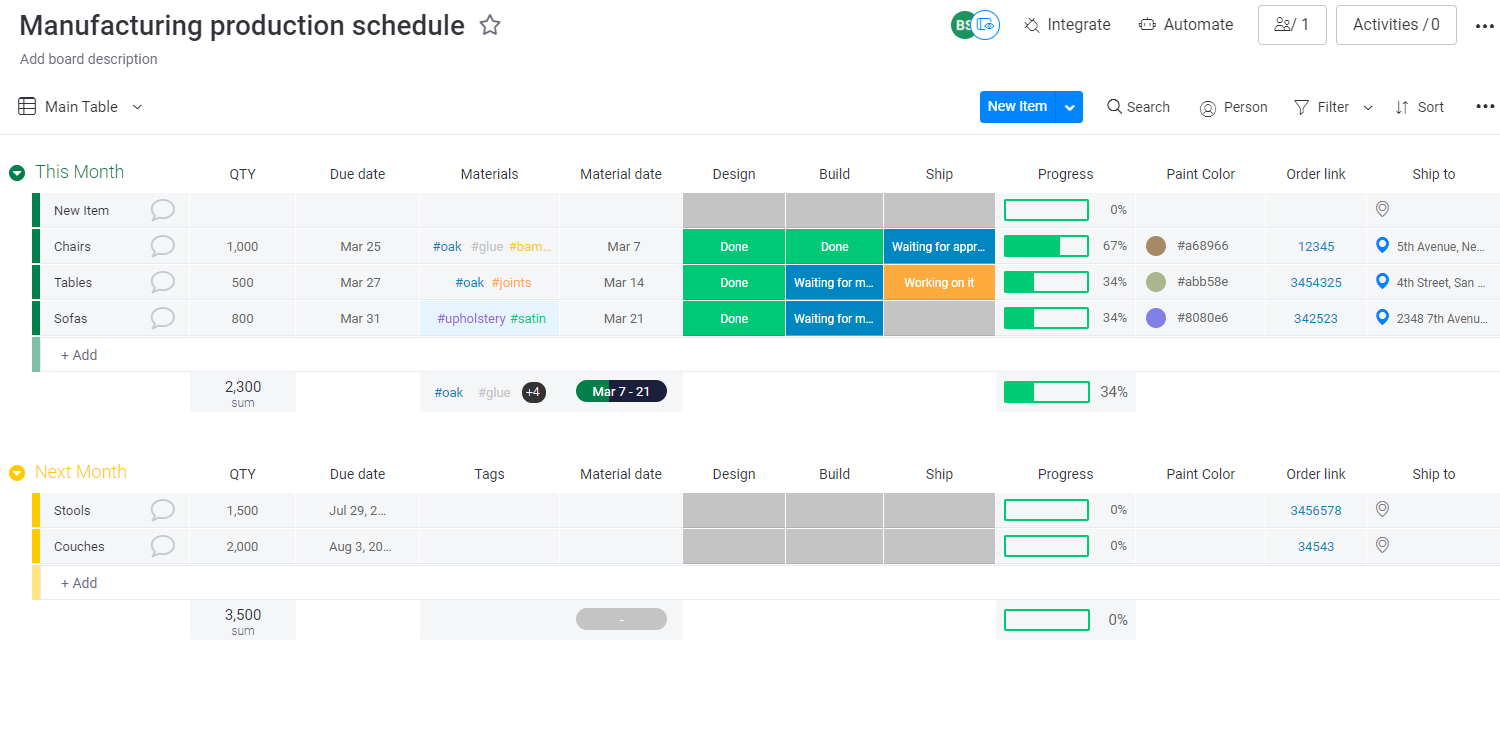

The ClickUp Production Tracking Template offers a comprehensive solution for any organization that needs to master production management. The template seamlessly integrates with the ClickUp ecosystem, so you can use the framework to streamline production tasks while taking advantage of the platform’s robust project planning tools .

The template allows you to meticulously map tasks, allocate resources, establish priorities, and identify dependencies by featuring an incredibly intuitive interface, complete with click-and-drag functionalities. The multiple views available let you create dynamic visualizations of the workflow to spot potential problems and remove them before they cause production issues.

ClickUp’s commitment to collaboration shines through in this template. It offers plenty of space for feedback, notes, and comments and informs teams with real-time updates. It’s a great way to avoid any issues with missed emails or poor version management because everything your team needs to stay on track is in one centralized hub.

Efficient production is vital for your bottom line, and the ClickUp Production Cost Analysis Template covers materials, labor, and overhead costs to help inform your decisions. You can gain insight into your production inefficiencies and forecast pricing impacts.

Product managers can leverage the template’s information to make better decisions and improve the production process. By gaining better cost visibility in your production process, you can optimize your resources and boost your long-term profitability and efficiency.

Let this template do the heavy lifting by collecting essential data and providing key actionable insights. It connects with the rest of the ClickUp platform, so it’s an excellent option if you already use the program as strategic planning software for your business.

Production planning templates offer a high-level view of your process, but you must also know the daily details. The ClickUp Daily Production Report Template is an excellent addition to your product development process , giving your team space to update everyone on daily events.

Using the template within the ClickUp platform allows you to create real-time insights and progress tracking for more efficient reporting and better decision-making.

The Daily Production Report Template offers total customization, including status, fields, and multiple view options to incorporate it with your workflow. It’s a great way to maintain oversight, provide accountability, and create transparent collaboration with your production team.

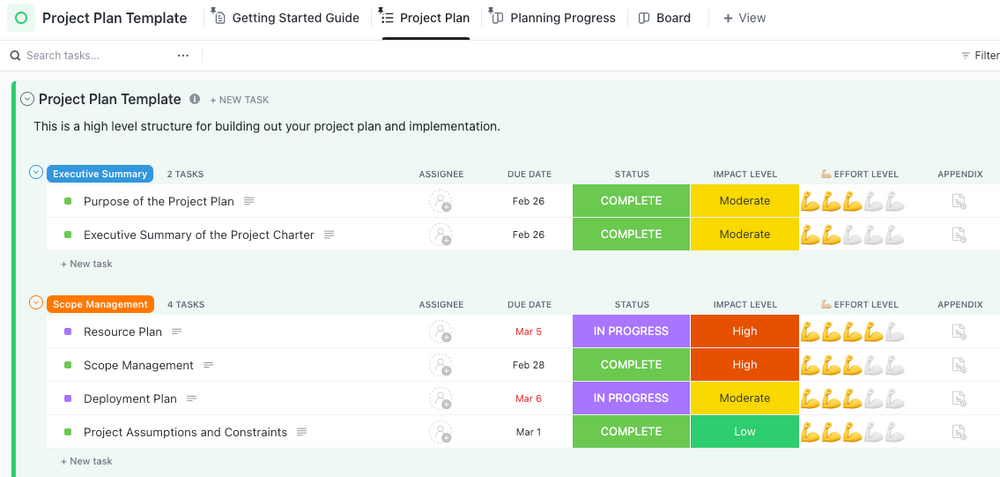

For those working specifically within the manufacturing industry, the ClickUp Manufacturing Project Plan Template will streamline the planning and organization process. The template has space for project objectives , manufacturing tasks, resource allocation, progress tracking, and more.

Execute your projects more effectively and efficiently while optimizing your budget and resources. With careful planning and this functional template, you’ll reduce operation costs and make your production line more profitable.

It’s a great addition to your ClickUp ecosystem and a perfect addition if you already use ClickUp as a CRM platform for manufacturers . Add this template to your current ClickUp lineup and see how it strengthens your manufacturing plans, making them faster and more cost-effective.

Learn about the best manufacturing schedule software !

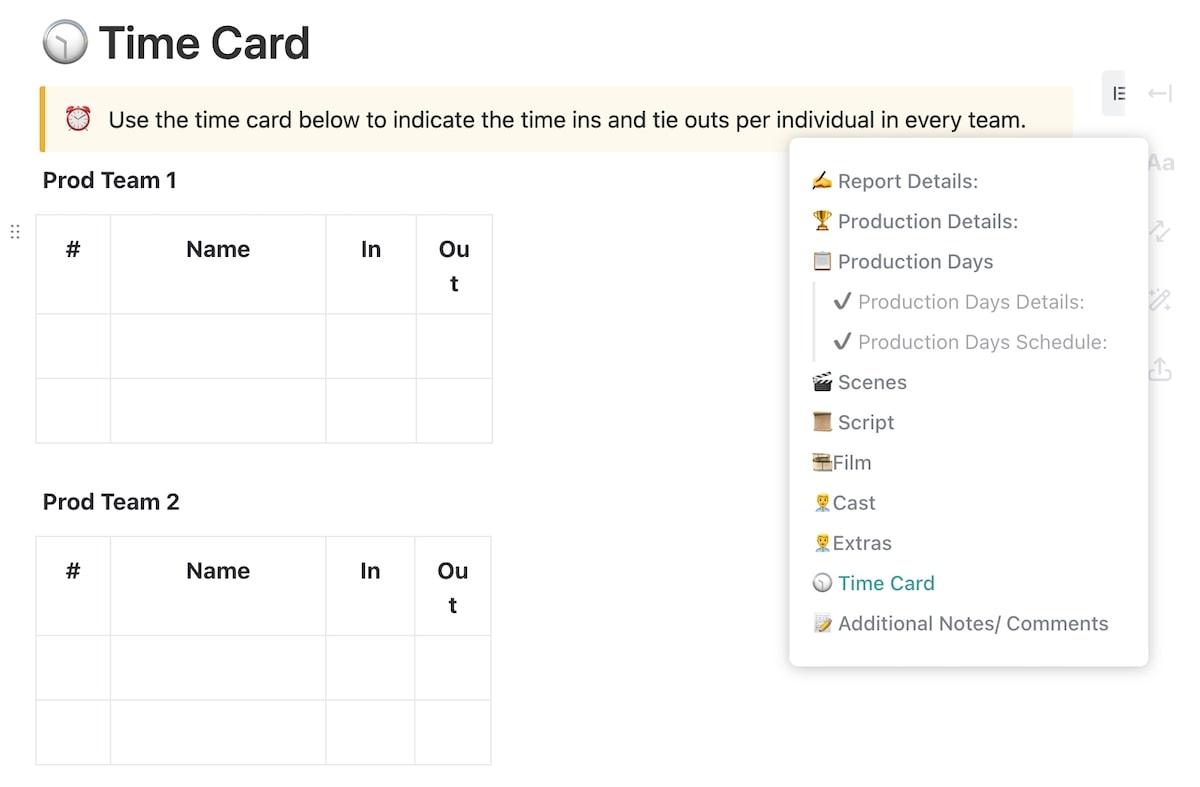

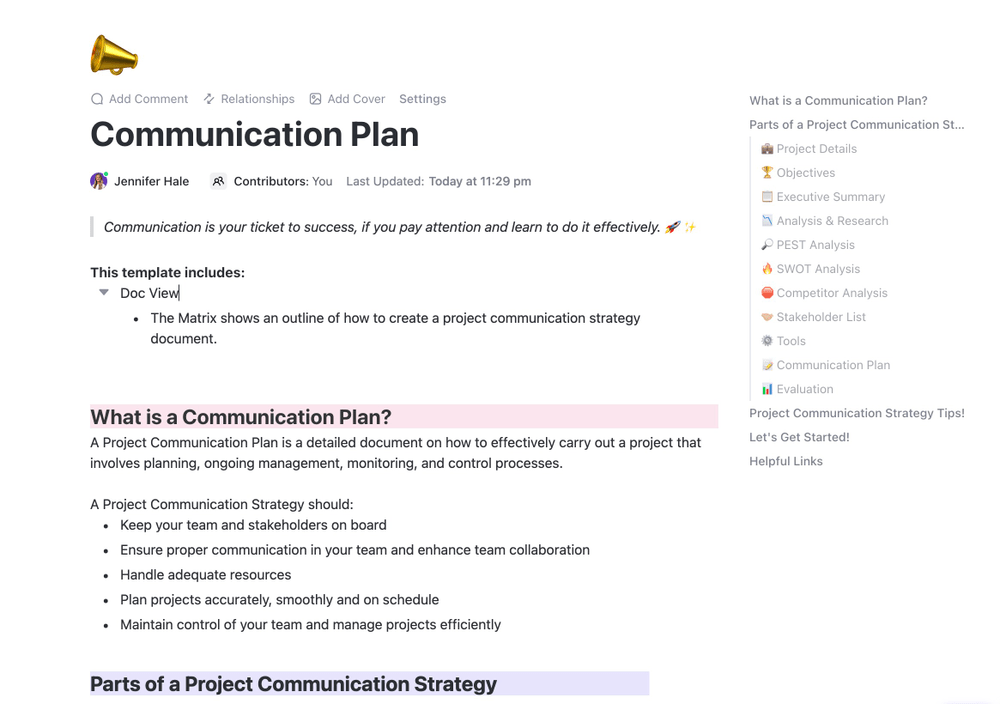

Our next free production schedule template is the ClickUp Manufacturing Communication Plan Template for better coordination and team collaboration, so you’ll avoid misunderstandings that may cause delays in the manufacturing processes.

This template helps you establish better communication paths between departments, suppliers, and stakeholders to keep information flowing and ensure everyone gets the same regular updates. Using this template, you’ll be able to document critical decisions and actions so everyone stays on the same page.

No matter the size of your operation, this template is a must-have in your collection of product management tools .

If your team operates on an Agile project management approach, sprint planning is a big part of your production plan. Make sprint planning more efficient with the ClickUp Sprint Planning Template . The template’s design makes it easier to plan each sprint, bringing clarity to a task regardless of complexity.

Use the platform’s many visualization features to create easy-to-read task planning and schedules because it plugs into ClickUp seamlessly. ClickUp’s collaborative features also make it easy for your team to keep the planning template current, so any project manager or team member can monitor progress throughout the sprint lifecycle and know where the team is at with every task on the list.

Are you looking for a way to keep your development team on track? The ClickUp Development Schedule Template is the resource you need, no matter what you’re working on and what stage of development you’re in.

The template streamlines creating a schedule with visual task management, collaborative features, real-time updates, and automated reminders. This keeps your team on track with tasks and ensures they meet deliverable deadlines.

The Development Schedule Template provides stakeholders with real-time updates. It’s a great way to update them on progress so they have the information they need at any time. With everything in one central hub, they can easily check progress while allowing the development team to continue working on their tasks.

You have an idea. Now, you need a plan to build it. The ClickUp Build Plan Template helps you organize your resources, timelines, and milestones to create a comprehensive plan for making your idea a reality.

From concept to launch, the build plan template becomes a roadmap where you can visualize tasks and progress while getting real-time updates from your team. It’s perfect for gaining clarity in each project development phase. It helps you set realistic deadlines while using internal and external resources wisely.

ClickUp’s free Build Plan Template offers plenty of customization options, including statuses, fields, and views, so you can tweak the template to suit the needs of your team. Use this template to create innovative plans for your next big idea.

This resource also works as a film production schedule template to align all departments and partners on development!

Are you trying to plan your next big software release? Keep your team on the same page with the ClickUp Release Planning Template . This is an alternative production planning template for those within the software development business. ClickUp designed the template to help oversee the launch of new software, giving you a way to organize your release plan strategically.

Start with plotting tasks, milestones, and dependencies to anticipate and remove potential bottlenecks. The template provides an insight into your team’s progress through each phase and helps you coach them to better performance.

From software inception to final deployment, the template creates a central hub for release planning, making it a seamless, collaborative effort. Take control over your release cycles and make them more efficient and effective for everyone involved.

If you’re looking for Excel templates, Simple Sheets has you covered. Its Excel Production Schedule template allows you to manage every aspect of your production process, from supply chain to operation rates, custom orders, and more.

Simple Sheets has carefully designed the spreadsheet with smart auto-population to save you from too much manual entry. Excel-savvy users can customize the spreadsheet to closely meet their team’s workflow process.

If you opt for this template, you’ll get all the benefits of working in the Excel environment, such as analyzing data and creating helpful charts to maximize efficiencies. The template is compatible with Google Sheets, too!

Track All the Production Activities and Resources in ClickUp

A great production schedule can be the backbone of your operation. It transforms the most complex processes into organized management steps. With a well-planned production schedule, you can oversee the timely delivery of goods and services while optimizing your resources and keeping everyone accountable for their responsibilities.

If you’re ready to take your production planning to the next level, check out ClickUp.

This productivity platform has a vast library of free templates to help you plan and organize your next project, whether refining an old project or developing something from the ground up. You can track tasks, allocate resources, and create timelines while working in a collaborative platform that puts communication and transparency first.

Revolutionize your production process on the ClickUp platform today!

Questions? Comments? Visit our Help Center for support.

Receive the latest WriteClick Newsletter updates.

Thanks for subscribing to our blog!

Please enter a valid email

- Free training & 24-hour support

- Serious about security & privacy

- 99.99% uptime the last 12 months

- Case Studies

- Free Coaching Session

Production Plan in Business Plan: A Comprehensive Guide to Success

Last Updated:

May 27, 2024

In any business venture, a solid production plan is crucial for success. A production plan serves as a roadmap that outlines the steps, resources, and strategies required to manufacture products or deliver services efficiently. By carefully crafting a production plan within a business plan, entrepreneurs can ensure optimal utilisation of resources, timely delivery, cost efficiency, and customer satisfaction. In this article, we will delve into the intricacies of creating an effective production plan in a business plan , exploring its key components, strategies, and the importance of aligning it with overall business objectives .

Key Takeaways on Production Plans in Business Planning

- A production plan : a detailed outline that guides efficient product manufacturing or service delivery.

- Importance of a production plan : provides a roadmap for operations, optimises resource utilisation, and aligns with customer demand.

- Key components : demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance.

- Strategies : lean manufacturing, JIT inventory, automation and technology integration, supplier relationship management, and continuous improvement.

- Benefits of a well-executed production plan : improved efficiency, reduced costs, enhanced product quality, and increased profitability.

What is a Production Plan?

A production Seamless Searches plan is a detailed outline that specifies the processes, resources, timelines, and strategies required to convert raw materials into finished goods or deliver services. It serves as a blueprint for the entire production cycle, guiding decision-making and resource allocation. The production plan considers factors such as demand forecasting, capacity planning, inventory management, and quality assurance to ensure efficient operations and optimal customer satisfaction.

Why is a Production Plan Important in a Business Plan?

The inclusion of a production plan in a business plan is vital for several reasons. First and foremost, it provides a clear roadmap for business operations, helping entrepreneurs and managers make informed decisions related to production processes. A well-developed production plan ensures that resources are utilised efficiently, minimising wastage and optimising productivity. This is particularly important for any startup platform aiming to streamline its production processes and achieve sustainable growth.

Additionally, a production plan allows businesses to align their production capabilities with customer demand. By forecasting market trends and analysing customer needs, businesses can develop a production plan that caters to current and future demands, thus avoiding overstocking or understocking situations.

Furthermore, a production plan helps businesses enhance their competitive advantage. By implementing strategies such as lean manufacturing and invoice automation , companies can streamline their production processes, reduce costs, improve product quality, and ultimately outperform competitors.

Key Components of a Production Plan

To create an effective production plan, it is crucial to consider several key components. These components work together to ensure efficient operations and successful fulfilment of customer demands. Let's explore each component in detail.

Demand Forecasting

Demand forecasting is a critical aspect of production planning. By analysing historical data, market trends, and customer behaviour, businesses can predict future demand for their products or services. Accurate demand forecasting allows companies to optimise inventory levels, plan production capacity, and ensure timely delivery to customers.

One approach to demand forecasting is quantitative analysis, which involves analysing historical sales data to identify patterns and make predictions. Another approach is qualitative analysis, which incorporates market research, customer surveys, and expert opinions to gauge demand fluctuations. By combining both methods, businesses can develop a robust demand forecast, minimising the risk of underproduction or overproduction. Utilising a free notion template for demand forecasting can further streamline this process, allowing businesses to organise and analyse both quantitative and qualitative data efficiently in one centralised location.

Capacity Planning

Capacity planning involves determining the optimal production capacity required to meet projected demand. This includes assessing the production capabilities of existing resources, such as machinery, equipment, and labour, and identifying any gaps that need to be addressed. By conducting a thorough capacity analysis, businesses can ensure that their production capacity aligns with customer demand, avoiding bottlenecks or excess capacity.

An effective capacity plan takes into account factors such as production cycle times, labour availability, equipment maintenance, and production lead times. It helps businesses allocate resources efficiently, minimise production delays, and maintain a consistent level of output to meet customer expectations.

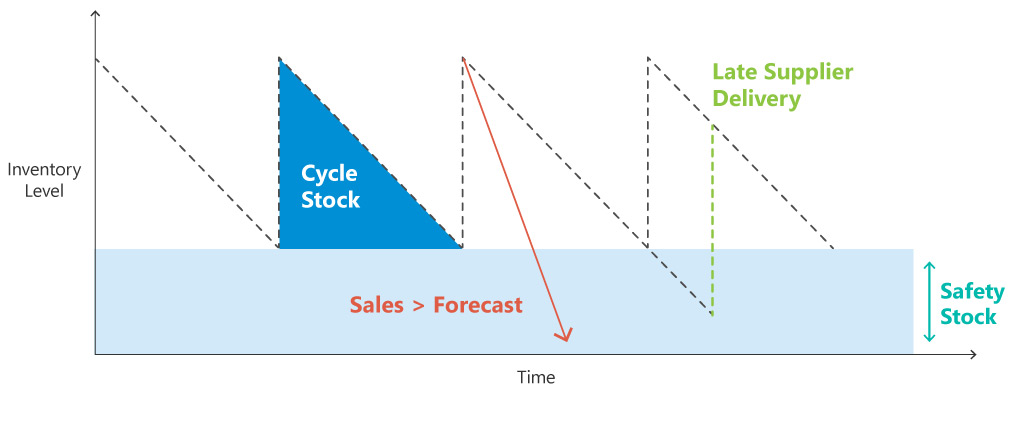

Inventory Management

Efficient inventory management is crucial for a successful production plan. It involves balancing the cost of holding inventory with the risk of stockouts. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring that sufficient stock is available to fulfil customer orders.

Inventory management techniques, such as the Economic Order Quantity (EOQ) model and Just-in-Time (JIT) inventory system, help businesses strike the right balance between inventory investment and customer demand. These methods consider factors such as order frequency, lead time, and carrying costs to optimise inventory levels and minimise the risk of excess or insufficient stock.

Resource Allocation

Resource allocation plays a pivotal role in a production plan. It involves assigning available resources, such as labour, materials, and equipment, to specific production tasks or projects. Effective resource allocation ensures that resources are utilised optimally, avoiding underutilisation or overutilisation.

To allocate resources efficiently, businesses must consider factors such as skill requirements, resource availability, project timelines, and cost constraints. By conducting a thorough resource analysis and implementing resource allocation strategies, businesses can streamline production processes, minimise bottlenecks, and maximise productivity.

Quality Assurance

Maintaining high-quality standards is essential for any production plan. Quality assurance involves implementing measures to monitor and control the quality of products or services throughout the production process. By adhering to quality standards and conducting regular inspections, businesses can minimise defects, ensure customer satisfaction, and build a positive brand reputation.

Quality assurance techniques, such as Total Quality Management (TQM) and Six Sigma , help businesses identify and rectify any quality-related issues. These methodologies involve continuous monitoring, process improvement, and employee training to enhance product quality and overall operational efficiency.

In addition to the core components of a production plan, it's also important for businesses to consider the broader aspects of their business strategy, including marketing and advertising. Understanding the costs and returns of different marketing approaches is crucial for comprehensive business planning. For instance, direct response advertising costs can vary significantly, but they offer the advantage of measurable responses from potential customers. This type of advertising can be a valuable strategy for businesses looking to directly engage with their target audience and track the effectiveness of their marketing efforts.

Strategies for Developing an Effective Production Plan

Developing an effective production plan requires implementing various strategies and best practices. By incorporating these strategies into the production planning process, businesses can optimise operations and drive success. Let's explore some key strategies in detail.

Lean Manufacturing

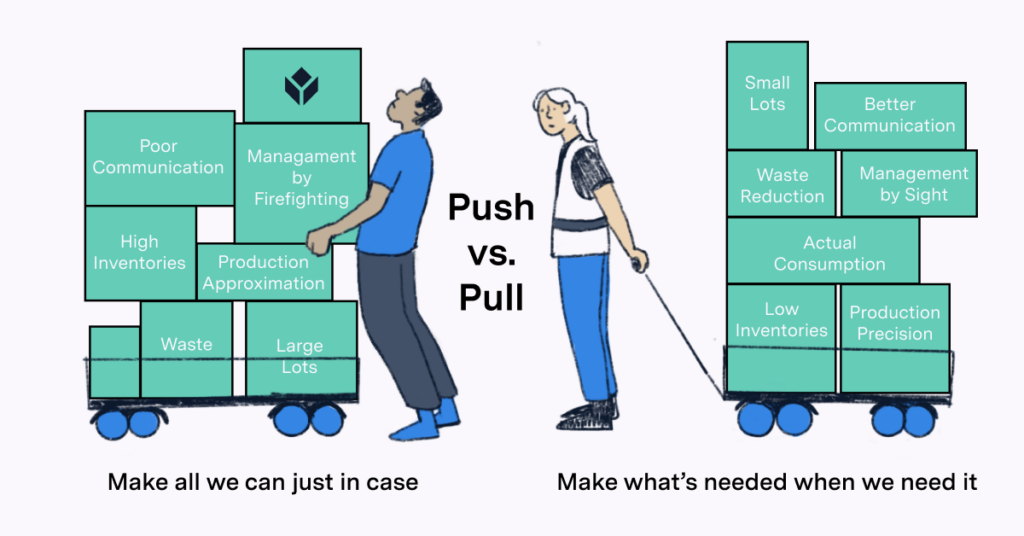

Lean manufacturing is a systematic Seamless Searches approach aimed at eliminating waste and improving efficiency in production processes. It emphasises the concept of continuous improvement and focuses on creating value for the customer while minimising non-value-added activities.

By adopting lean manufacturing principles, such as just-in-time production, standardised work processes, and visual management, businesses can streamline operations, reduce lead times, and eliminate unnecessary costs. Lean manufacturing not only improves productivity but also enhances product quality and customer satisfaction.

Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory is a strategy that aims to minimise inventory levels by receiving goods or materials just when they are needed for production. This strategy eliminates the need for excess inventory storage, reducing carrying costs and the risk of obsolete inventory.

By implementing a JIT inventory system, businesses can optimise cash flow, reduce storage space requirements, and improve overall supply chain efficiency. However, it requires robust coordination with suppliers, accurate demand forecasting, and efficient logistics management to ensure timely delivery of materials.

Automation and Technology Integration

Automation and technology integration play a crucial role in modern production planning, as well as mobile app development . By leveraging technology, businesses can streamline processes, enhance productivity, and reduce human error. Automation can be implemented in various aspects of production, including material handling, assembly, testing, and quality control.

Continuous Improvement

Continuous improvement is a fundamental principle of effective production planning. It involves regularly evaluating production processes, identifying areas for improvement, and implementing changes to enhance efficiency and quality.

By fostering a culture of continuous improvement, businesses can drive innovation, optimise resource utilisation, and stay ahead of competitors. Techniques such as Kaizen, Six Sigma, and value stream mapping can help businesses identify inefficiencies, eliminate waste, and streamline production workflows.

Frequently Asked Questions (FAQs)

What is the role of a production plan in business planning.

A1: A production plan plays a crucial role in business planning by providing a roadmap for efficient production processes. It helps align production capabilities with customer demand, optimise resource utilisation, and ensure timely delivery of products or services.

How does a production plan affect overall business profitability?

A2: A well-developed production plan can significantly impact business profitability. By optimising production processes, reducing costs, and enhancing product quality, businesses can improve their profit margins and gain a competitive edge in the market.

What are the common challenges faced in production planning?

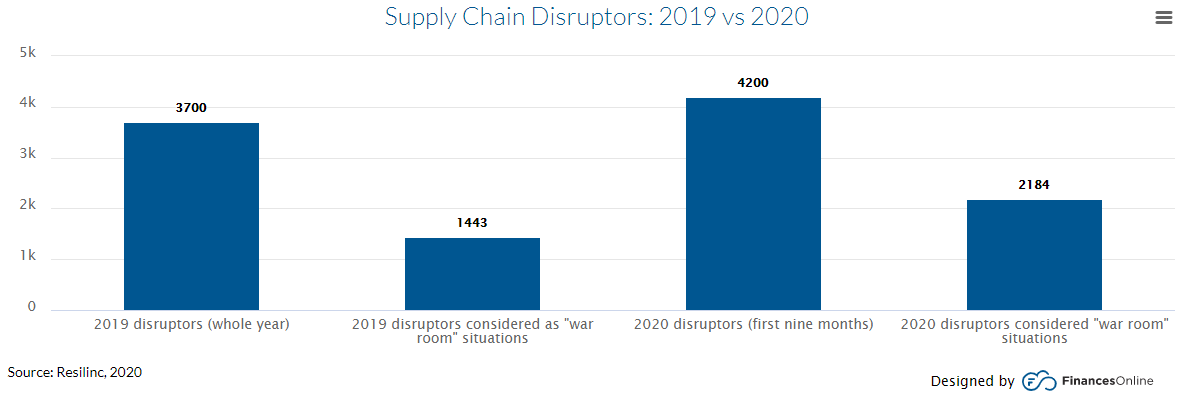

A3: Production planning can present various challenges, such as inaccurate demand forecasting, capacity constraints, supply chain disruptions, and quality control issues. Overcoming these challenges requires robust planning, effective communication, and the implementation of appropriate strategies and technologies.

What is the difference between short-term and long-term production planning?

A4: Short-term production planning focuses on immediate production requirements, such as daily or weekly schedules. Long-term production planning, on the other hand, involves strategic decisions related to capacity expansion, technology investments, and market expansion, spanning months or even years.

How can a production plan be adjusted to accommodate changes in demand?

A5: To accommodate changes in demand, businesses can adopt flexible production strategies such as agile manufacturing or dynamic scheduling. These approaches allow for quick adjustments to production levels, resource allocation, and inventory management based on fluctuating customer demand.

In conclusion, a well-crafted production plan is essential for business success. By incorporating a production plan into a comprehensive business plan, entrepreneurs can optimise resource utilisation, meet customer demands, enhance product quality, and drive profitability. Through effective demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance, businesses can streamline production processes and gain a competitive edge in the market.

People Also Like to Read...

Are You Ready For Your Expansion Plans?

How To Build Your Digital Marketing Plan

© 2016 - 2024 Robin Waite. All rights reserved.

Production planning and scheduling for manufacturing

Production planning and scheduling is essential to increase your manufacturing efficiency. Adjust your production schedule based on inventory, resources, and orders. Learn how with Katana.

James Humphreys

Production scheduling is essential for growing manufacturing operations to take their production to the next level. If you’re looking to maximize efficiency on your shop floor, you need a way to optimize your production planning and scheduling.

Nowadays, your scaling manufacturing business has many options for finding production planning software explicitly crafted for manufacturers.

This guide will provide you with a comprehensive understanding of manufacturing scheduling and how it can help you allocate your resources efficiently and cost-effectively to meet customer orders. So, read on to learn how to improve production scheduling in your scaling manufacturing business.

What’s the difference between planning and scheduling?

Production planning and scheduling are two key activities in manufacturing and operations management. Although closely related, they involve different aspects of the production process. Let’s take a closer look at the difference between these two concepts.

What is production planning?

Production planning is an important process that involves strategic decision-making to determine the optimal production strategy, resource allocation, and scheduling to meet customer demand and organizational objectives. It encompasses a comprehensive analysis of what products should be produced, in what quantities, and when.

By considering market demand, sales forecasts, and internal capabilities, production planning ensures efficient utilization of resources while maintaining a competitive edge in the market. This process plays a vital role in aligning the overall business strategy with the operational aspects of production, enabling companies to meet customer expectations, maximize productivity, and achieve their desired outcomes.

The main objectives of production planning include:

- Forecasting customer demand and market trends

- Setting production goals and objectives

- Determining the types and quantities of products to be produced

- Identifying the necessary resources (materials, equipment, labor, etc.)

- Allocating resources efficiently

- Developing manufacturing schedules and timelines

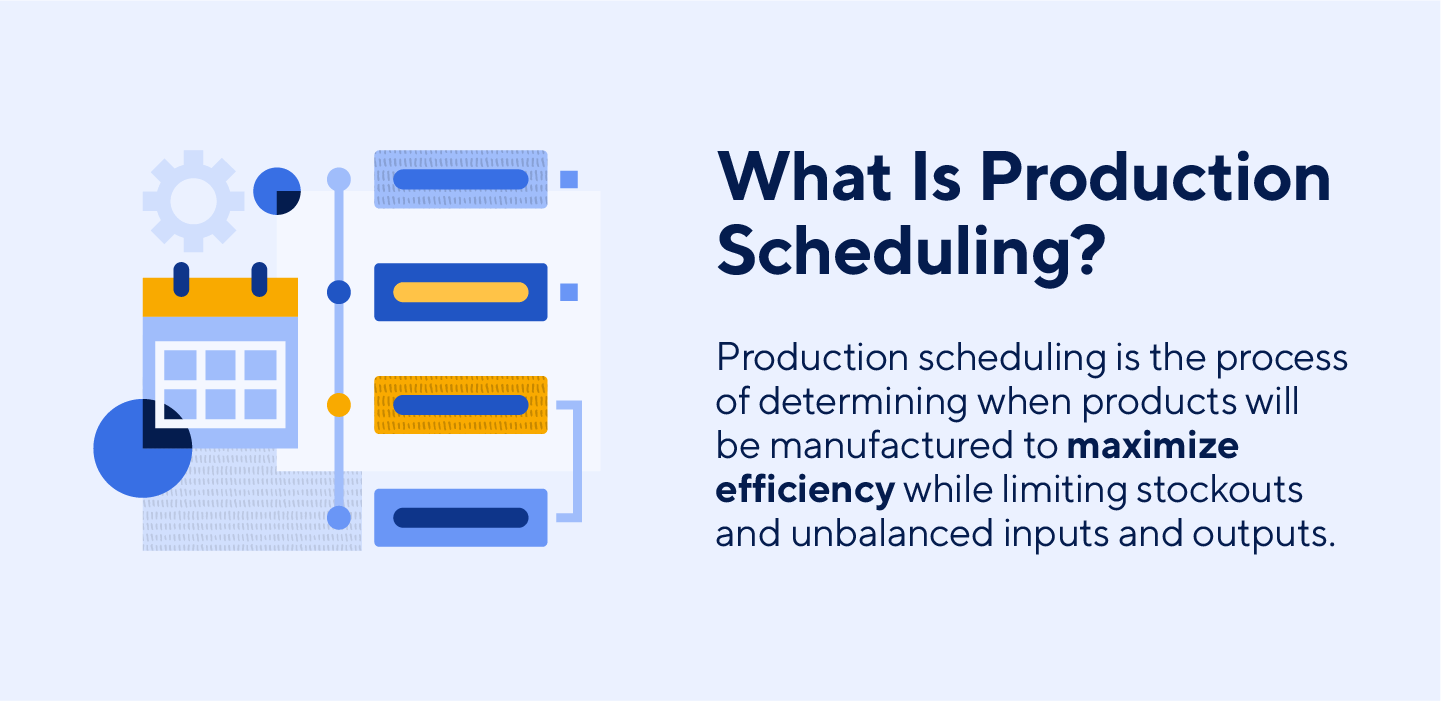

What is production scheduling?

Production scheduling is a vital process that entails the creation of a comprehensive and detailed timetable outlining the specific order and timing of production activities. It involves making critical decisions on when each task or operation should commence and conclude, taking into account resource availability, constraints, and dependencies.

By considering factors such as machine availability, labor capacity, and material availability, production scheduling aims to optimize efficiency and streamline workflow.

This process ensures that production tasks are executed in a coordinated manner, minimizing idle time, maximizing resource utilization, and ultimately facilitating the timely delivery of products.

Effective manufacturing scheduling plays a pivotal role in enhancing productivity, reducing costs, and maintaining a smooth and well-organized production process.

The primary objectives of production scheduling include:

- Sequencing the order of production tasks

- Assigning resources (equipment, labor, etc.) to specific tasks

- Minimizing idle time and maximizing resource utilization

- Adapting to changes in customer demand or unforeseen disruptions

- Ensuring timely delivery of products

In summary, production planning focuses on the big picture and long-term decisions to ensure that production activities align with the overall business strategy and customer demand. On the other hand, production scheduling focuses on short-term decisions that aim to optimize efficiency, minimize costs, and maintain a smooth workflow within the production process.

Both planning and scheduling are essential for effective production management and meeting customer demands efficiently.

The importance of production planning and scheduling

Production planning and scheduling are crucial aspects of a business’ operations and have significant importance for several reasons:

- Meeting customer demands — Effective manufacturing planning and scheduling ensure timely delivery of products in the required quantities, avoiding stockouts , minimizing lead times, and enhancing customer satisfaction.

- Optimal resource utilization — Proper planning and scheduling enable businesses to allocate resources efficiently, minimizing idle time, reducing costs, and maximizing productivity, leading to improved operational efficiency and resource utilization.

- Cost control — Accurate demand forecasting and efficient scheduling help avoid overproduction, minimize inventory holding costs, reduce setup times, eliminate bottlenecks, and optimize resource use, contributing to cost savings.

- Improved production efficiency — Effective planning streamlines production processes, eliminates inefficiencies, and reduces waste, optimizing production flow, reducing cycle times, and increasing overall efficiency.

- Timely decision-making — Well-defined plans facilitate informed decisions on resource allocation, production priorities, and capacity management, enabling adaptation to changes and ensuring timely production.

- Coordination and collaboration — Manufacturing planning and scheduling involve cooperation between departments, enhancing communication, improving coordination, and achieving a synchronized production process, reducing delays and enhancing operational efficiency.

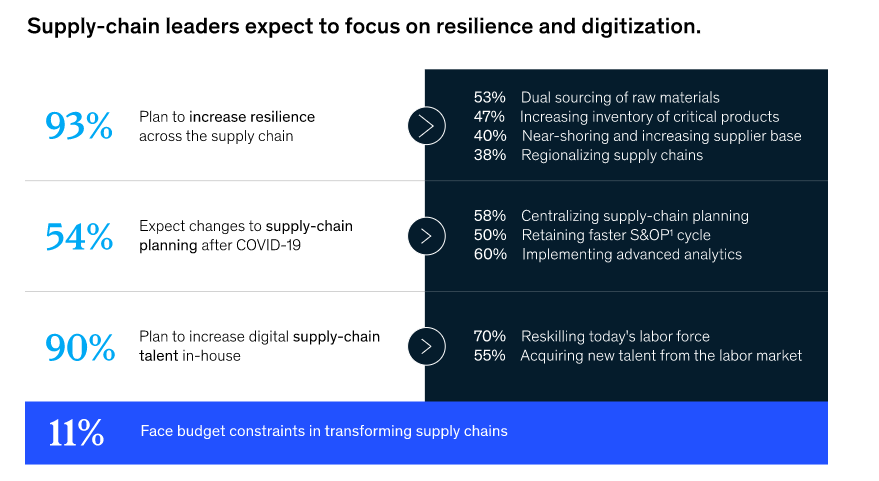

- Scalability and growth — Well-designed production plans and schedules lay the foundation for handling increased demand, expanding operations, and adapting to market conditions. This helps to facilitate scalability and capitalizing on growth opportunities.

- Continuous improvement — Monitoring production performance, analyzing data, and evaluating schedules help identify areas for improvement, driving continuous optimization and maintaining a competitive edge.

So, if you want to ensure timely delivery, optimal resource utilization, cost control, improved efficiency, and scalability, you need to have a solid production plan.

5 stages of production planning and scheduling

Production planning and scheduling involve a systematic approach to ensure efficient and timely production of goods. The best way to achieve this is by dividing the process into four distinct stages, each serving a specific purpose.

These stages provide a structured framework for organizations to plan, schedule, and control their production processes effectively. Let’s explore each stage in detail.

1. Demand forecasting and capacity planning

The first production planning and scheduling stage involves demand forecasting and capacity planning.

Demand forecasting entails estimating future customer demand based on historical data, market trends, and other relevant factors. It helps organizations determine the expected demand volume and patterns for their products.

To forecast demand, you need to incorporate a variety of data, including:

- Historical sales performance

- Local and national taxes and regulations

- Current manufacturing trends and predictions

- Technological advancements

Learning and understanding your product demand will help you make the best choices when arranging and improving your operations.

Once the demand is forecasted, capacity planning comes into play.

It involves evaluating the production capacity and capabilities of the organization to determine if it can meet the projected demand. Factors such as workforce availability, equipment capacity, and facility constraints are taken into account during this stage.

The goal is to align the production capacity with the anticipated demand to avoid underutilization or overburdening of resources.

2. Material planning and procurement

The second stage focuses on inventory control , including material planning and procurement. In this stage, organizations identify the raw materials, components, and resources required for production. The quantities needed are determined based on the manufacturing schedule and demand forecast.

Efficient material planning ensures the timely availability of materials while minimizing inventory costs and the risk of shortages or excess stock.

Establishing strong supplier relationships is essential during this stage to ensure a reliable supply chain. Organizations collaborate with suppliers to coordinate delivery schedules, negotiate pricing, and maintain consistent quality standards.

Effective material planning and procurement help optimize production flow and prevent disruptions in the supply chain.

3. Scheduling and resource allocation

The third stage involves detailed scheduling and resource allocation. It focuses on creating a comprehensive production timeline and sequence of activities to ensure smooth operations.

Scheduling involves assigning tasks to different workstations or production lines, considering factors such as equipment availability, setup times, and dependencies between jobs.

Resource allocation is another crucial aspect of this stage. It entails determining the optimal allocation of labor, equipment, and other resources to specific production tasks. Balancing workloads, considering skill levels, and maximizing resource utilization are key considerations during resource allocation.

The goal is to create an efficient schedule that minimizes idle time, bottlenecks, and unnecessary delays.

4. Production control and monitoring

The fourth stage revolves around production control and monitoring. Once production is underway, it is essential to track work progress, ensure adherence to the planned schedule, and maintain quality standards. Production control is all about monitoring the production process, identifying deviations or bottlenecks, and taking corrective actions as necessary.

Efficient production control relies on real-time data collection, performance measurement, and analysis. It enables organizations to identify issues, make adjustments, and optimize the production flow. This stage also includes quality control measures to ensure the final output meets the required standards and customer expectations.

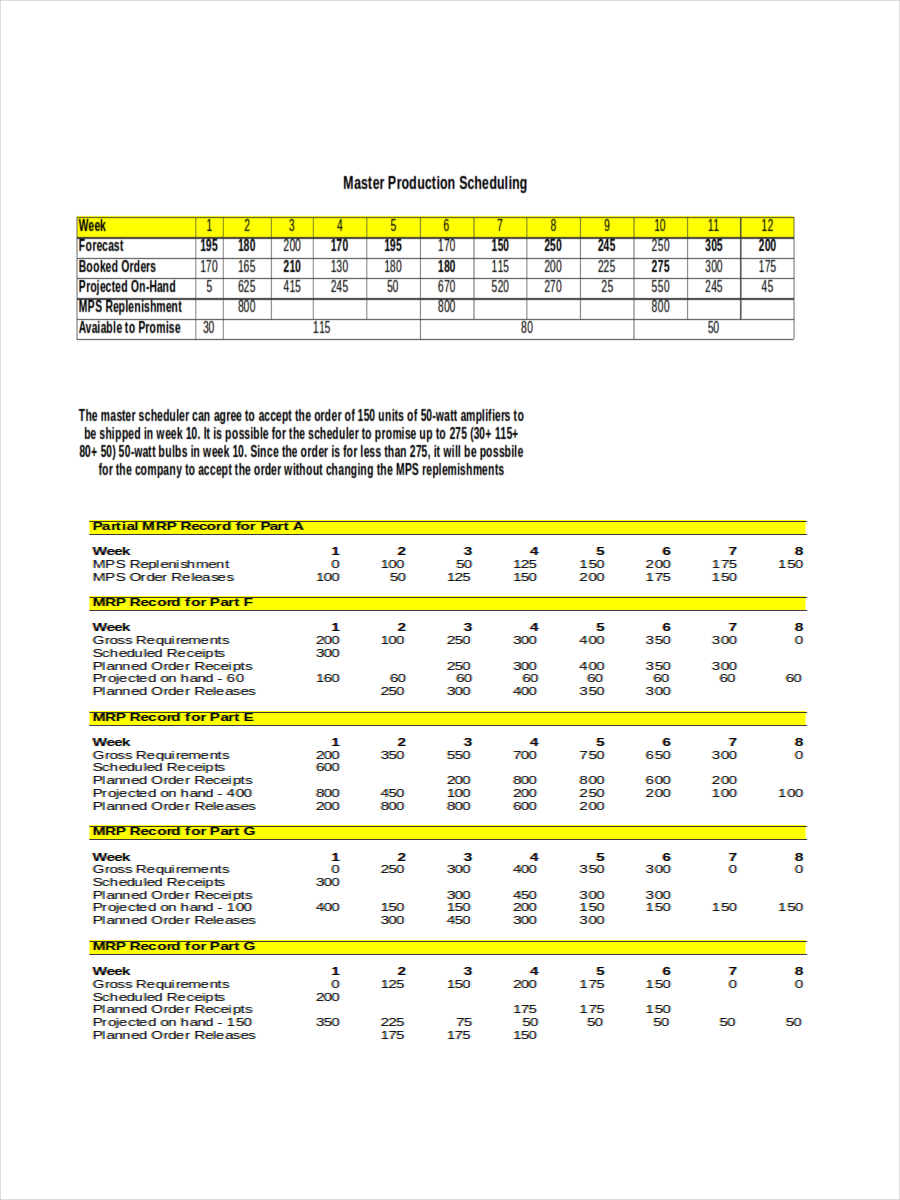

5. Master production schedules

Once your manufacturing plan looks achievable, you can progress to the next step, producing a master production schedule , the ultimate document for production.

Your master production schedule (MPS) will detail how many items need to be produced within a certain period. Most manufacturers use manufacturing technology to create an MPS that will provide real-time data and allow manufacturers to make production changes on the fly.

By effectively controlling and monitoring the production process, organizations can improve productivity, minimize waste, and ensure timely delivery of products to customers.

Download a production schedule template

Download this free production schedule template for Excel to create an efficient and accurate production plan for your business.

A simple production plan example

Imagine a small but modest workshop with five artisans making psychedelic T-shirts.

Each artisan works eight hours a day, from Monday to Friday. They follow a make-to-stock workflow in a job shop setting. It takes 2 hours to produce a single T-shirt.

The max capacity of this Funkadelic business is 200 hours .

In this scenario, the annual hippie fest is fast approaching — and looking at your historical data collection — the T-shirt makers expect to see a surge in sales. Last year they were overwhelmed, so this year, they have decided to put together a quick manufacturing plan a week before they expect an increase in demand. They also want to have a safety stock level of ten for each of their items.

As per their initial plan, they won’t be able to meet production requirements, but they can now use this knowledge to readjust their current production plan. They decide to limit the production of Far Out T-shirts to 40 and Peace T-shirts to 8 .

They can still meet the forecasted demand with the modified plan by sacrificing some of the safety stock.

However, this plan put their operations and resources at 100% capacity . If one of the artisans calls in sick on Wednesday evening, the max capacity for the week falls to 176 hours . When planning production, a rule of thumb is to have 20% free to give yourself wiggle room if a problem occurs.

The key factors to consider when scheduling production

Production planning is vital for any manufacturing business. Even basic products need a clear and defined flow to turn them from raw materials into quality goods. If you don’t follow this flow or your production quality control checklist , your products will surely drop in quality. Without a proper process, your standardized practices will be forgotten.

So, when scheduling the production, what are the key factors to consider?

Crew management

Use your team well.

Your people are a valuable asset to your business. They play a key part in manufacturing process optimization. Make it your business to know your people, including their strengths and weaknesses. This way, you can assign each team member to the most suitable tasks and machines.

If someone is sick or goes on holiday, you have the additional capacity to make up for the temporary loss.

Effective production planning allows you to get the most out of your people and machines. Every team member knows the tasks assigned to them and what their expected output is. Keeping tabs on this process lets you compensate for shortfalls and keep up with high demand.

Running at capacity

Is your workshop constantly running at 100% of its output?

It only takes a minor bump to bring things to a grinding halt. Capacity planning helps to make sure you’re not running at max capacity. If you do receive an unusually large order or two, you will be glad you prepared.

The same goes for your team, as they have enough resources to do their job on time.

Raw materials

Frequent stalls in production planning mean paying team members and machines to stand by.

Integrating a robust MRP or manufacturing ERP software into your business can help ensure you always have the required raw materials available. This means:

- You never have to push back production because of supply order delays or stockouts.

- Priority deadlines do not have to be set back due to undersupply.

- There’s no need to constantly step over excess raw materials on your shop floor.

If done right, warehousing and transport costs won’t skyrocket due to oversupply. As a bonus, every team member always has something to do as they work with your available materials.

Workshop logistics

The logistical flow of each part of your manufacturing process also requires consideration. This may not seem so important, but you would be surprised. Many production lines have come grinding to a halt as one weak link has been placed on the wrong stage.

Pushing machines and people to unsuitable locations can harm efficiency.

Sometimes, what seems like common sense could be harmful to your flow. It takes careful analysis to determine how materials, resources, people, and supplies travel around your shop floor.

It may be that a more efficient layout or order exists for your business. Sometimes a small change can make a world of difference to your production schedule.

Problem-solving

Trial-and-error problem-solving costs your business money through each failed attempt.

Overordering or overproducing is a band-aid solution, as this leads to extra costs or staff burnout. You need effective production planning software to track your flow and find manufacturing scheduling issues to get to the root of a problem.

Know your manufacturing processes

Understanding manufacturing planning and scheduling allow you to oversee your manufacturing methodically to overcome production issues easily.

Track and manage everything effectively, and everything should run like clockwork. Effective manufacturing scheduling makes it easier to do everything by the book — it is set out clearly for your whole team and is available 24/7.

Production planning KPIs

Now you know everything there is to know about putting together your production plan — the next step is understanding how to measure its effectiveness. Here are some KPIs to track to get you started:

- Manufacturing costs — Track how much it costs to produce an item by looking into raw materials, utilities, salaries, rent, etc.

- Capacity utilization rate — You don’t want resources running at max capacity, but you don’t want machinery or workstations sitting idle.

- Planned production vs. actual hours — This will help you better understand how long it takes to produce an item or uncover any issues which lead to delays on your shop floor.

- Employee utilization (productivity) — The same as your capacity rate. The only difference is that you don’t want to overwork them. Make sure you schedule your human resources reasonably to void burnout.

- Takt time — A lean manufacturing concept that looks into the actual time it takes to produce a single unit of item.

This checklist will guide you in creating your business analytics to observe your production and develop plans to make them even more efficient.

But, as you can tell, doing this is a long and arduous process, and many scaling manufacturers turn to automation to help them with this task.

How to optimize production scheduling

Optimizing production scheduling involves maximizing efficiency, minimizing costs, and ensuring timely delivery of products. Below you’ll find some strategies for optimizing manufacturing scheduling.

Demand-driven scheduling

Incorporate demand-driven scheduling by aligning manufacturing schedules with customer demand. Use accurate demand forecasting to determine the required production volume and adjust schedules accordingly. This approach helps avoid overproduction or underproduction and reduces excess inventory or stockouts.

Utilize advanced scheduling techniques

Employ advanced scheduling techniques such as finite capacity scheduling, just-in-time (JIT) scheduling, or theory of constraints (TOC) to optimize production schedules. These techniques consider capacity constraints, setup times, and dependencies between tasks to create efficient and realistic schedules.

Optimize resource allocation

Ensure optimal utilization of resources by assigning tasks based on skill levels, availability, and efficiency. Consider the capabilities and capacities of equipment, machinery, and workforce while allocating resources. Efficient resource allocation minimizes idle time, reduces bottlenecks, and improves overall productivity.

Minimize changeovers and setup times

Reduce changeover and setup times by implementing strategies like single-minute exchange of die (SMED). Streamlining changeover processes allows faster transitions between different product configurations, enabling shorter production runs and increased flexibility.

Implement real-time monitoring

Utilize real-time monitoring systems and production control tools to track progress, identify bottlenecks, and make data-driven decisions. Real-time data provides insights into the actual status of production, enabling prompt adjustments and proactive problem-solving.

Prioritize critical tasks

Identify critical tasks or processes that significantly impact the overall production timeline. Prioritize these and allocate resources accordingly to ensure timely completion. Focusing on critical tasks minimizes the risk of delays in the entire production process.

Consider production constraints

Take into account any constraints that may affect production scheduling, such as limited capacity, equipment maintenance schedules, or supplier lead times. By incorporating these constraints into the scheduling process, you can avoid scheduling conflicts and optimize production flow.

Implement lean manufacturing principles

Apply lean manufacturing principles such as just-in-time production , continuous flow, and waste reduction techniques to optimize production scheduling. Eliminate non-value-added activities, reduce inventory, and optimize process flows to improve overall efficiency.

Embrace technology

Utilize production scheduling software or manufacturing execution systems (MES) with advanced planning and scheduling capabilities. These tools automate the scheduling process, optimize resource allocation, and provide real-time visibility into production activities, enabling better decision-making and scheduling optimization.

Continuous improvement

Foster a culture of continuous improvement by regularly reviewing and analyzing production schedules, performance metrics, and feedback. Identify areas for improvement, implement changes, and monitor the impact of these adjustments. Continuously striving for optimization ensures ongoing efficiency gains in production scheduling.

By implementing these strategies, organizations can optimize their production scheduling processes, enhance operational efficiency, minimize costs, and deliver products on time, ultimately improving customer satisfaction and competitiveness.

Production planning and scheduling mistakes

Production planning and scheduling mistakes can lead to inefficiencies, delays, increased costs, and customer dissatisfaction. Let’s review some common mistakes to avoid in manufacturing planning and scheduling.

Inaccurate demand forecasting

Failing to accurately forecast customer demand can result in overproduction or underproduction. Overproduction leads to excess inventory and increased carrying costs , while underproduction can result in stockouts and missed sales opportunities. It is important to gather and analyze relevant data, consider market trends, and collaborate with sales and marketing teams to improve demand forecasting accuracy.

Insufficient capacity planning

Inadequate evaluation of production capacity can lead to resource constraints and bottlenecks. If the production capacity does not align with the forecasted demand, it can result in missed deadlines, backlogs, and delays in fulfilling customer orders. Conducting regular capacity assessments and considering factors such as equipment maintenance, workforce availability, and facility constraints are essential for effective manufacturing capacity planning .

Poor material planning

Inaccurate material planning can cause disruptions in the production process. Insufficient stock of raw materials or components can halt production, while excessive inventory ties up capital and increases storage costs. Utilizing efficient inventory management systems, establishing reliable supplier relationships, and continuously monitoring material requirements are crucial to avoid material planning errors.

Inefficient scheduling

Inefficient scheduling can lead to production issues, increased setup times, and idle resources. Poor task sequencing, inadequate consideration of setup times, and neglecting resource availability can result in unnecessary delays and production bottlenecks. Utilizing advanced scheduling techniques, considering the dependencies between tasks, and optimizing resource allocation is vital for efficient scheduling.

Lack of flexibility

Failure to incorporate flexibility in manufacturing planning and scheduling can make it challenging to adapt to unforeseen events or changes in demand. Market fluctuations, machine breakdowns, and supplier delays can disrupt the planned schedule. It is important to build contingency plans, have backup suppliers, and maintain buffer capacity to accommodate unexpected disruptions and maintain operational continuity.

Ignoring feedback and continuous improvement

Neglecting to gather feedback from the production floor, customer feedback, and performance metrics can hinder process improvement.

Regularly reviewing production performance, analyzing data, and actively seeking feedback from relevant stakeholders can help identify areas for improvement and drive continuous optimization in production planning and scheduling.

Lack of communication and collaboration

Poor communication and collaboration among departments can lead to misalignment and delays. Production planning and scheduling require coordination among different teams, including sales, operations, procurement, and logistics.

Clear communication channels, regular cross-functional meetings, and shared visibility of information are essential for effective collaboration and synchronization of activities.

By avoiding these common production planning and scheduling mistakes and adopting best practices, organizations can enhance their operational efficiency, minimize costs, and improve customer satisfaction by consistently delivering products on time and as per requirements.

Can you use Excel for production planning?

The absence of affordable production planning software has led to many manufacturers using inefficient spreadsheets .

There are three main problems with this approach:

- Spreadsheets are slow — It may be better than doing it with a pen and paper, but Excel is still too labor-intensive.

- Spreadsheets are error-prone — They are vulnerable to mistakes that cause confusion, production delays, and business-disrupting problems.

- Spreadsheets are static — They do not update automatically. This can lead to delays as changes are not communicated.

Many modern manufacturers are stuck with Excel because they can’t see better options.

This is understandable. Most manufacturers do not need the gargantuan flow diagrams and Gantt charts seen in large enterprise software. Shop-bought software like Excel seems like a quick and easy option.

But it is not powerful enough for using production management effectively.

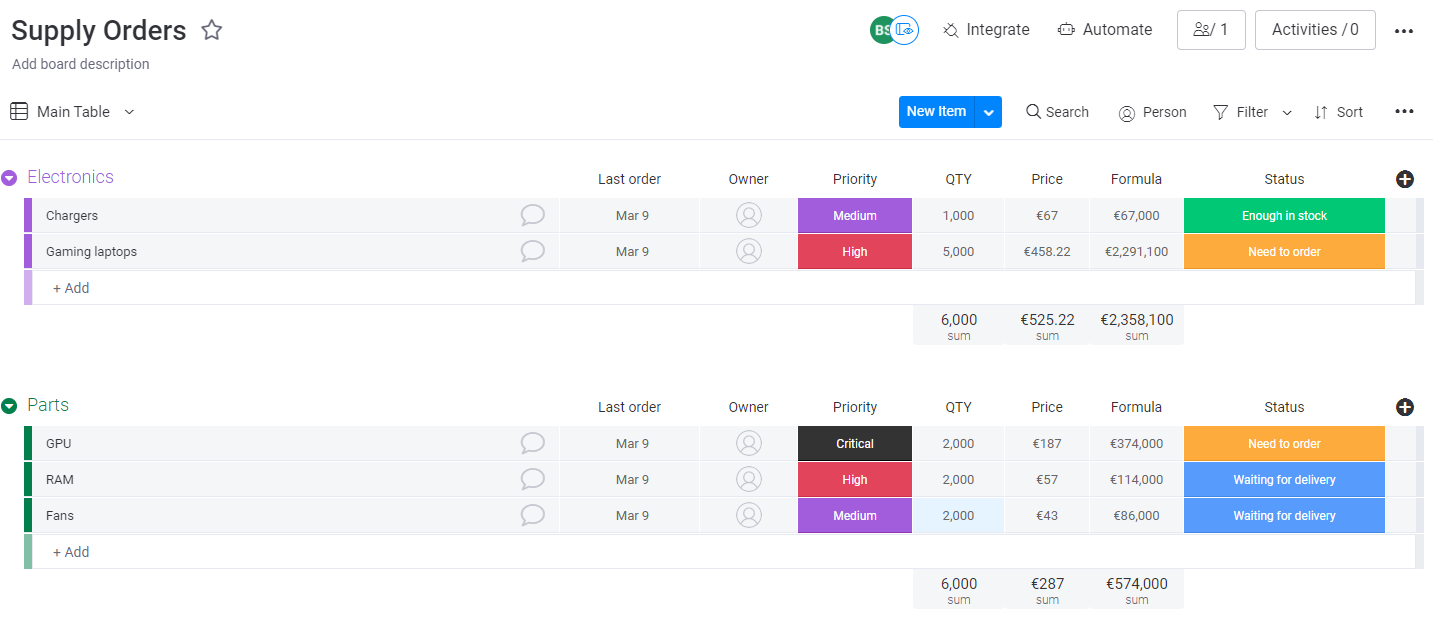

Production planning and scheduling with Katana

The best way to avoid production planning mistakes and implement different optimization techniques is through software. Katana is a cloud manufacturing platform that allows you to do all that and more. It offers advanced features with an intuitive interface, so you don’t need a 3-month boot camp to start using it.

Let’s have a look at what production planning with Katana looks like.

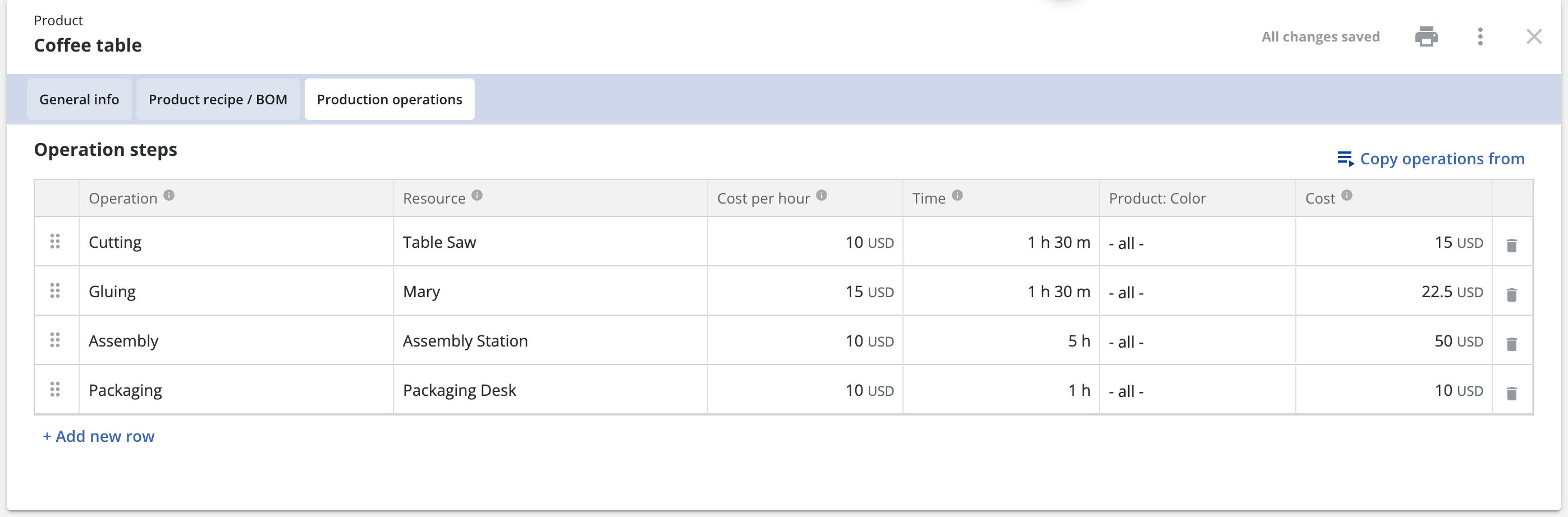

The Production operations tab lets you do production planning as it automatically assigns team members and workstations to each process your manufacturing orders require. It also calculates all the resources needed and associated costs.

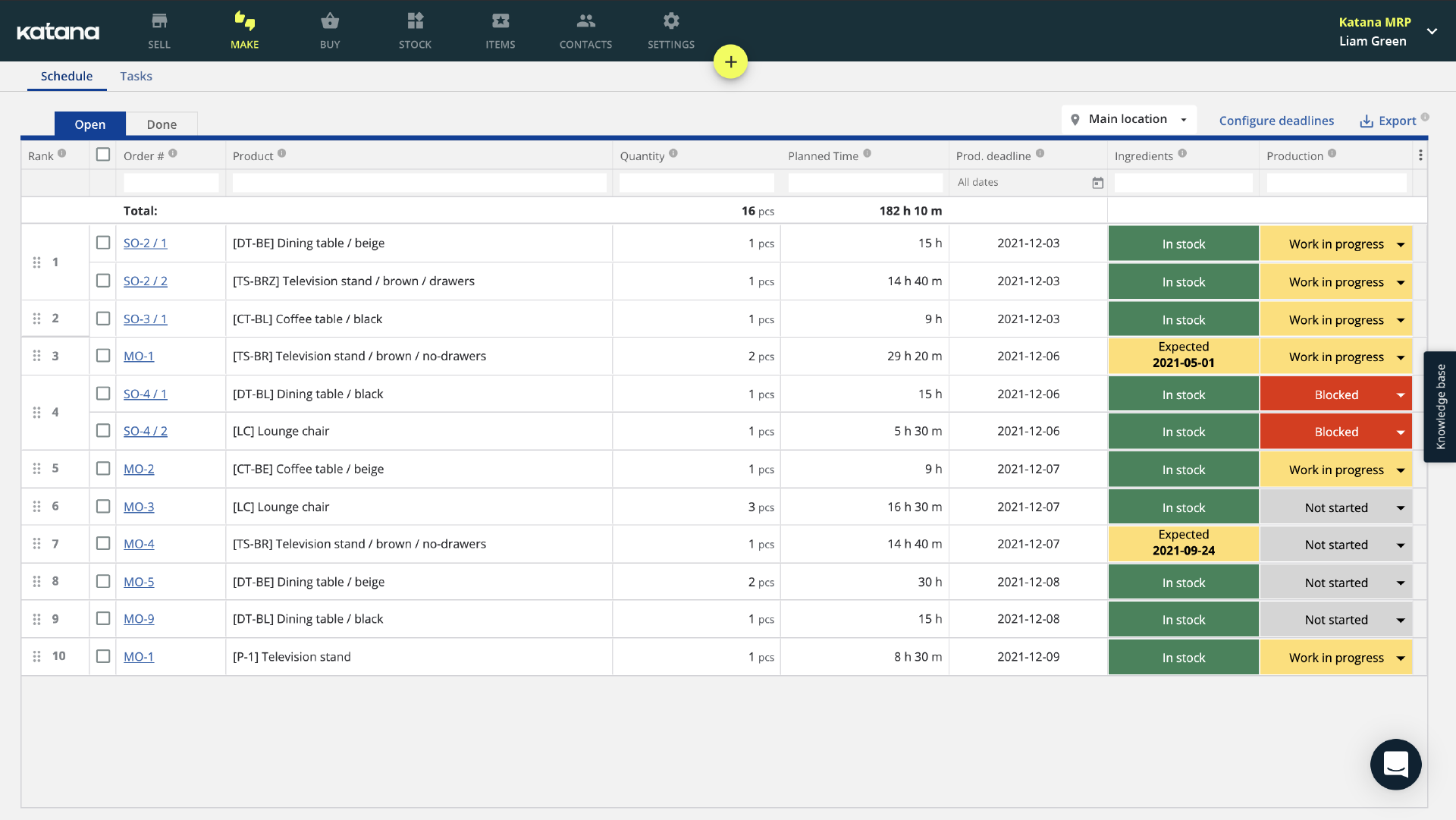

The Make screen lets you review all outstanding manufacturing tasks. If something comes up, or you want to change tack, simply reorganize your manufacturing queue, and Katana’s real-time master planner reallocates all resources to ensure the prioritized orders get out of the door first.

Production planning with Katana allows you to:

- Generate forecasts and plan inventory

- Prevent idle time in your workshop

- Significantly reduce scheduling errors

- Generate accurate, realistic deadlines

- Minimize inventory transport and storage costs

- Identify inefficiencies that could lead to production bottlenecks

- Gets products out the door and to customers on time

Take control of your production processes with Katana. Request a demo today to see it in action.

Table of contents

Get inventory trends, news, and tips every month, explore all categories, get visibility over your sales and stock.

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control

What Is a Production Schedule, and What Should It Include?

Discover the importance of a production schedule and its main components. Use Motion to create a comprehensive production schedule that meets deadlines.

As a business owner or manager, you know that time is money. That’s why having a well-planned production schedule is crucial to the success of your business, whether you’re producing cars, cakes, or content.

Often overlooked, this behind-the-scenes process is the heart of any production operation, orchestrating the seamless coordination between resources, tasks, and timelines.

While production scheduling has always been important, technological advancements and data-driven approaches have changed the game.

The old days of static spreadsheets and disjointed workflows are fading away. Now, a wave of innovation is empowering businesses to streamline their operations, minimize their downtime, and increase their productivity.

Ready to maximize output like never before? We’ll tell you how to create and implement a production schedule — and how Motion can help.

What is a production schedule?

A production schedule is a detailed plan that outlines the specific activities and timeline for producing goods or services. It is a crucial component of production management, helping businesses efficiently allocate resources and meet production targets.

In simple terms, a production schedule is like a to-do list for a business to make things. It is a plan that shows what needs to be done, when it should be done, and how long it will take to complete each task.

Imagine you have a bakery, and you want to make and sell different types of cakes. A production schedule would outline the specific steps and timings for making each cake.

For example, it might say that on Monday morning, you need to gather all the ingredients, and in the afternoon, you mix the batter. You bake the cakes on Tuesday, and on Wednesday, you decorate them. The schedule also includes when the cakes will be ready for sale.

A production schedule helps you organize your work and ensure everything happens smoothly. It helps you know what needs to be done next and how long it will take so that you can plan your resources accordingly.

That way, you can avoid running out of supplies, manage your time effectively, and deliver your project on time — satisfying your customers.

Considerations to make when creating a production schedule

There are a few factors you should consider when crafting a production schedule. Here are just a few of them:

Production capacity

How much can you produce within the given timeframe?

Production capacity is the maximum number of goods that you can produce within a given timeframe. Establishing this number before creating your schedule is important, as it will affect the timeline for each production run.

Demand forecast

How much demand do you think there will be for your product or service?

Estimating how much demand there will be for your product or service will help you to plan how much to produce at each step of the process. You can use past sales data, market research, and other information to make an educated guess.

How long will the process take, from the raw material procurement to the final product delivery?

Lead time is the amount of time it takes from when you order raw materials to when you deliver the final product. This factor can have a big impact on how long it takes to complete each run, so make sure to factor it in when creating your schedule.

Material availability

Do you have all the raw materials, components, and supplies you need?

Having all the items you need is vital to completing a run successfully. Unfortunately, only 22% of companies have a proactive supply chain, which means that most businesses struggle with material availability. So be sure to plan ahead before starting a new production run.

Equipment and machinery

Do you have the right equipment to manufacture your goods?

Make sure you have the correct tools and other equipment throughout the production schedule. Be sure to check that all of your equipment is functioning properly and that you have backups in case of breakdowns.

Labor availability and skills

Do you have the right number of people, and do they have the correct skills?

Having enough workers with the right skills helps ensure that production will run smoothly and finish on time.

What goes into a production schedule?

Creating a production schedule takes a bit of time and effort, but it’s worth it to ensure that you meet your long-term goals . Here is a list of information to include in your production schedule for timely delivery and quality outcomes:

Tasks and activities

This is the first and most crucial step in creating a production schedule. List all the tasks involved in the production process, from procuring the raw materials to shipping and packaging. That way, everyone involved in the process can understand what’s expected of them.

A good task manager can help you keep track of everything as you go along. Check out Motion’s Task Manager to help you stay on top of your tasks.

Sequence of operations

Next, determine the order in which you need to execute your tasks. Arranging the tasks in a logical sequence helps keep the production process moving smoothly and delays at bay.

Set start and end dates for each task or activity in the production schedule to keep everything on track. This allows everyone involved to keep the expected delivery date in mind and work to ensure that all tasks are completed on time.

Resource allocation

This part of creating a production schedule is about making sure the right people have the necessary resources at each stage. Ensure that everyone can do their tasks efficiently through either skilled labor or productivity tools .

Constraints and considerations

It’s highly unlikely that your production schedule will go off without a hitch. Even the most comprehensive plan can encounter hurdles, including unforeseen challenges or delays, at any time.

Make a list of constraints and considerations that could potentially derail your production schedule. These could relate to budget, legal requirements, customer demand, or market conditions. It’s a good idea to incorporate extra time to account for any unexpected events.

Benefits of creating a production schedule

Creating a production schedule has many benefits. Planning ahead lets your team accomplish more in less time.

Efficient use of resources

Up to 20% of every dollar spent in the manufacturing industry is wasted.

A well-designed production schedule can help you efficiently allocate resources, thus reducing wastage and overall costs.

Improved productivity

A production schedule acts as a kind of product roadmap that everyone on the team can follow in pursuit of a common work goal . With clearly defined roles and deadlines, team members know what’s expected of them and can work more efficiently and productively.

Delivering products on time

With a work schedule in place, your team will know exactly when each product will be ready for market. This can help you set realistic and achievable deadlines.

Team alignment

When every team member has access to a production schedule, they’re aware of each other’s workloads and can plan their work accordingly. This can help prevent confusion and optimize team productivity.

Using Motion to create a production schedule enhances team collaboration and coordination among team members. A centralized platform for task and deadline management is a great way to keep everyone aligned throughout the production process.

Continuous improvement

Your production schedule can provide insights into what’s working and what isn’t. You can use this information to make adjustments and improve the process in the future. This helps your team remain nimble and responsive to change, improving your organization’s resilience in the face of competitors.

One concrete example of continuous improvement in manufacturing comes from The Raymond Corporation . They implemented lean management techniques, such as defect reduction, visual management, and active quality control circles. Because of these initiatives, the company was able to double its production volume and increase overall quality by 35% over three years. Such remarkable growth in production efficiency could not have been achieved without a culture of continuous improvement.

More satisfied customers

Delivering quality goods on time and in full helps you build a good reputation among your customers. This can translate to repeat business and more referrals. When you prioritize quality and delivery, you give customers a reason to come back for more.

5 stages of production scheduling

Creating a clear and robust production schedule is easier when you break the process down into stages. The five stages of production scheduling are as follows:

1. Planning

Set production goals and assess the availability of resources to achieve them. You can then create a plan that outlines the specific steps you need to take to meet those goals.

Production planning is vital to ensuring that your team knows the direction in which they’re heading and that everyone is on the same page.

Routing involves identifying the operations required to produce each product and the most efficient production path. Carefully analyze every step in the production process, from gathering the raw materials to the product’s completion.

The goal here is to come up with a streamlined production process that minimizes waste, maximizes output, and meets the quality standards you set.

3. Scheduling

Essentially, this step involves creating a timeline to ensure that each stage of production is completed on time.

Assign start and end dates for each operation. Assess the production capacity needed for them, and ensure that resources are available as necessary.

4. Dispatching

Next, issue work orders to the production team and assign tasks to individual workers.

At this stage, it’s essential to ensure that each worker knows what they’re supposed to do during the process. Clear communication between team members is crucial to ensuring that everyone works effectively.

5. Execution

The fifth and final stage is execution.

At this stage, the team follows the production plan according to the schedule and work orders. You monitor progress and adjust the manufacturing schedule as needed to ensure that everything runs smoothly. The goal is to run an efficient production process, meet the quality standards you set, and produce output on time.

Keep your production schedule on track with Motion

A production schedule can make or break the success of any project. Luckily, there’s an easy and effective way to streamline the production scheduling process: Motion.

Motion automates the process of production scheduling, eliminating the tedious and time-consuming aspects of the job. With it, you can easily keep your team members informed and on track, ensuring that each step of the production process is completed on time and within budget.

Whether you’re new to project management or a seasoned professional, Motion can help take your operations to the next level. So why not give it a try today? Sign up for a free 7-day trial .

Related articles

13 Time Management Techniques to Boost Your Productivity

Understanding the Sprint Backlog and How to Use It

What Are Long-Term Goals? (+50 Examples & Tips to Achieve Them)

Put motion to the test., tech and media companies are talking about motion.

- Digital Marketing

- Apps & Website

The Ultimate Guide to Efficient Production Planning and Scheduling

- Key Takeaways

According to Statista, 85% of manufacturers consider production planning and scheduling software crucial for their operations in 2024.

Gartner’s latest report reveals that by 2024, AI-driven production planning solutions will reduce manufacturing downtime by 30% globally.

SEMrush data from 2024 shows that companies integrating advanced scheduling technologies experience a 25% increase in production efficiency.

Effective production planning and scheduling are vital for maximizing productivity, minimizing costs, and meeting customer demands efficiently.

Monitoring key performance indicators (KPIs) and leveraging data-driven insights drive continuous optimization and enhance competitiveness in the manufacturing landscape.

Have you ever wondered how products magically appear on store shelves exactly when you need them? Behind this seemingly effortless process lies the intricate art of production planning and scheduling. Picture a symphony where each note is meticulously orchestrated to create a harmonious melody. Similarly, production planning harmonizes demand forecasts, resource allocation, and scheduling to ensure products are available when and where they are needed. But what does it truly entail, and how does it shape the world of manufacturing?

Overview of Production Planning

- Definition and purpose of production planning

Production planning is the strategic process used in manufacturing to determine the what, when, and how of production. It involves forecasting demand, scheduling production activities, and allocating resources efficiently to meet market demands. The main goal is to optimize the use of resources, minimize production costs, and ensure timely delivery of products.

- Importance in the manufacturing process

- Central to the manufacturing process, production planning ensures resources are used efficiently, reducing waste and maximizing output.

- It helps in scheduling the production runs, maintaining inventory at optimal levels, and improving the overall productivity of the manufacturing unit.

- Proper planning can lead to increased production capacity, improved product quality, and higher customer satisfaction.

- Relationship between production planning and business strategy

- Production planning is tightly interwoven with business strategy, impacting a company’s ability to meet market demands and achieve financial targets.

- Strategic planning in production helps in aligning manufacturing goals with the business objectives, enhancing the ability to respond to competitive pressures and market opportunities.

- It supports long-term business success by ensuring that the manufacturing process is efficient, cost-effective, and aligned with the broader business goals.

The Production Planning Process

- Steps involved in production planning

- Identify Objectives: Establish clear goals for production, including quantity, quality, and timeline requirements.

- Demand Forecasting: Analyze market trends, historical data, and sales forecasts to predict future product demand.

- Resource Assessment: Evaluate the availability of resources such as materials, labor, and machinery needed for production.

- Capacity Planning: Determine the production capacity to meet forecasted demand, considering constraints like machine availability and labor skills.

- Process Design: Define the production process, including the sequence of operations, required equipment, and labor needs.

- Scheduling: Develop a detailed production schedule that outlines when and where each product will be manufactured.

- Execution: Implement the production plan, coordinating resources and monitoring the production process.

- Monitoring and Control: Track production progress, compare actual performance against the plan, and make adjustments as needed.

- Key phases from demand forecasting to final execution

- Demand Forecasting Phase: Involves analyzing past sales data, market trends, and economic indicators to predict future product demand.

- Planning Phase: Translates the forecasted demand into a viable production plan, determining the quantity of products to be produced and the required resources.

- Scheduling Phase: Involves creating a timeline for when each task in the production process should be completed.

- Execution Phase: The actual production takes place based on the planning and scheduling phases, with a focus on efficiency and adherence to the plan.

- Monitoring and Control Phase: Ongoing assessment of the production process to ensure it aligns with the plan, with adjustments made as necessary to address any issues.

- Role of technology in modern production planning

- Automation of Tasks: Technology automates repetitive tasks in the production planning process, increasing efficiency and reducing errors.

- Data Analysis and Forecasting: Advanced data analytics tools help in accurately forecasting demand and optimizing resource allocation.

- Real-time Monitoring: Modern systems provide real-time visibility into the production process, enabling quick decision-making and adjustments.

- Integration of Systems: Technology integrates various aspects of production planning, such as inventory management, procurement, and scheduling, for streamlined operations.

- Machine Learning and AI: These technologies are increasingly used to predict trends, automate scheduling, and optimize production processes for better outcomes.

Types of Production Planning

- Flow Production Planning and its Characteristics

- Definition : Flow production planning involves continuous movement of materials through the production process. This method is often used in large-scale manufacturing where products go through a series of steps and processes in a fixed sequence.

- Standardization : Products are usually standardized, allowing for a streamlined and efficient production process.

- Automation : High levels of automation are common, reducing manual labor and increasing consistency.

- Continuous Operation : Production runs continuously over long periods, optimizing machinery use and reducing setup times.

- High Volume : Suitable for high-volume production where demand is consistent and predictable.

- Cost Efficiency : Economies of scale can be achieved, lowering the per-unit cost of production.

- Mass Production Planning and its Efficiency

- Definition : Mass production planning is focused on producing large quantities of standardized products. It is characterized by the assembly line system where each worker or machine performs a specific task repetitively.

- Economies of Scale : Significant reduction in cost per unit as production volume increases.

- Standardized Products : Uniformity in products helps in streamlining the manufacturing process and reducing variability.

- Specialized Labor and Machinery : Workers and machines specialize in specific tasks, increasing speed and efficiency.

- Inventory Management : Often involves maintaining large inventories to ensure a continuous production flow.

- Time-Saving : The assembly line reduces the time taken from start to finish, enhancing overall productivity.

- Process Production Planning and its Application

- Definition : Process production planning is used in industries where production is continuous and the output is in the form of a product flow, such as chemicals, oil, and gas.

- Continuous Flow : Production occurs in a continuous, unbroken flow through a series of processes or operations.

- Chemical Processes : Commonly used in chemical manufacturing where raw materials undergo chemical reactions to form new products.

- Customization and Flexibility : Allows for some level of customization, depending on the complexity of the process and the end-product requirements.

- Quality Control : Rigorous quality control is essential to ensure that the output remains consistent and meets the required standards.

- Integration with Other Systems : Often integrated with other production and business planning systems to ensure smooth operations and efficient resource use.

Demand Forecasting and Product Demand Planning

- Techniques for predicting market demand

- Historical Sales Analysis: Examining past sales data to identify trends and patterns that can predict future demand.

- Market Research: Conducting surveys, interviews, and focus groups to gather information on consumer preferences and buying behaviors.

- Delphi Method: Using a panel of experts to forecast demand through iterative rounds of questioning and consensus building.

- Time Series Analysis: Employing statistical techniques to model and forecast future demand based on historical time series data.

- Econometric Modeling: Utilizing advanced statistical methods to forecast demand by considering various economic factors like GDP, unemployment rates, and consumer spending.

- Impact of demand forecasting on production planning

- Resource Allocation: Accurate demand forecasting helps in determining the required quantity of resources, including labor, materials, and machinery, ensuring they are adequately allocated to meet production needs.

- Inventory Management: Facilitates optimal inventory levels, preventing overstocking or stockouts, and reducing holding costs.

- Capacity Planning: Assists in planning the production capacity needed to meet future demand, helping in the decision-making process for expansion or downsizing.

- Lead Time Reduction: Enables better planning of the production schedule, reducing lead times and improving customer satisfaction.

- Risk Management: Provides a basis for identifying potential risks in the supply chain and developing strategies to mitigate them.

- Tools and software used in demand planning

- SAP Integrated Business Planning (SAP IBP): Offers advanced analytics for demand planning, helping businesses to make accurate forecasts and optimize inventory levels.

- Oracle Demand Management Cloud: Provides capabilities for demand sensing, shaping, and forecasting, helping to improve the accuracy of demand predictions.

- IBM Planning Analytics: Uses AI and machine learning to provide insights into demand trends, helping businesses to forecast demand more accurately.

- Microsoft Dynamics 365 Supply Chain Management: Includes demand forecasting features that allow for the creation of demand forecasts based on historical data.

- Anaplan: A cloud-based platform that provides tools for demand planning, allowing businesses to model different scenarios and their potential impacts on demand.

Material Requirement Planning (MRP)

- Understanding the MRP System

- What It Is: Material Requirement Planning (MRP) is a system used to manage manufacturing processes. It helps in planning and controlling inventory levels, production, and delivery schedules.

- Functionality: MRP calculates the materials needed for production and the timing to procure them. It uses data from production schedules, inventory records, and bill of materials (BOM) to ensure that materials are available for production and products are ready for delivery.