- Login [Admin or PGR students only]

- Latest additions

- Simple search

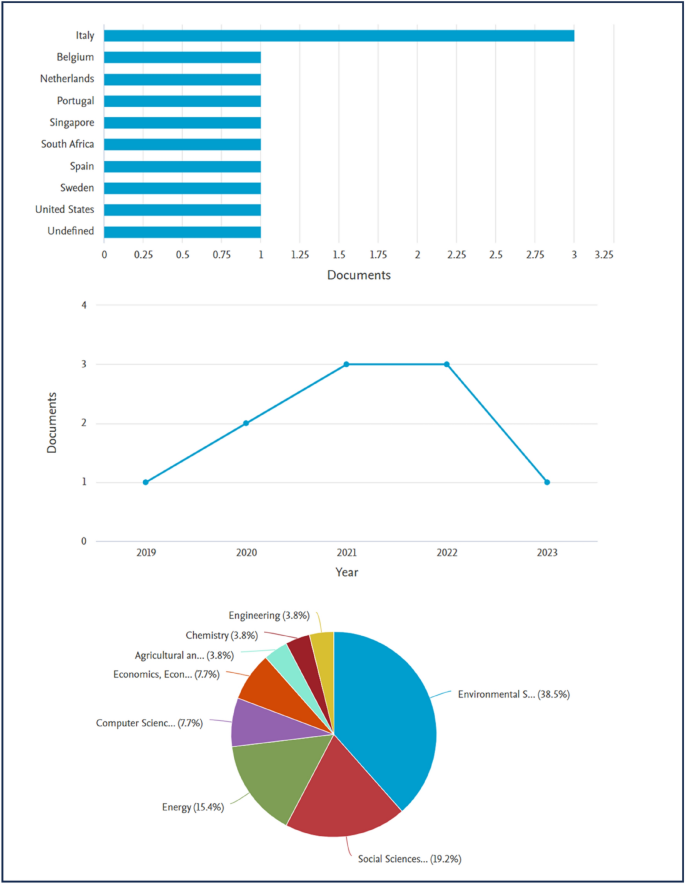

- Advanced search

- Browse by Year

- Browse by Subject

- Browse by Department

- Browse by Author

- Open access

- Repository policies

Circular supply chain management: A definition and structured literature review

--> DOI https://doi.org/10.1016/j.jclepro.2019.04.303

Circular economy is increasingly recognized as a better alternative to the dominant linear (take, make, and dispose) economic model. Circular Supply Chain Management (CSCM), which integrates the philosophy of the circular economy into supply chain management, offers a new and compelling perspective to the supply chain sustainability domain. Consequently, there is increasing research interest. However, a review of the extant literature shows that a comprehensive integrated view of CSCM is still absent in the extant literature. This prohibits a clear distinction compared to other supply chain sustainability concepts and hinders further progress of the field. In response, this research first classifies various terminologies related to supply chain sustainability and conceptualizes a unifying definition of CSCM. Using this definition as a base, it then conducts a structured literature review of 261 research articles on the current state of CSCM research. Based on the review results, the researchers call for further studies in the following directions that are important but received little or no attention: design for circularity, procurement and CSCM, biodegradable packaging, circular supply chain collaboration and coordination, drivers and barriers of CSCM, circular consumption, product liabilities and producer's responsibility, and technologies and CSCM.

Item Metadata

| Item Type: | Article |

|---|---|

| Uncontrolled Keywords: | Supply chain management; Circular economy; Circular supply chain; Circular supply chain management; Sustainable supply chain; Sustainability |

| Divisions: | |

| SWORD Depositor: | Unnamed user with email |

| Depositing User: | Unnamed user with email |

| Date Deposited: | 17 Nov 2020 14:43 |

| Last Modified: | 16 May 2024 20:20 |

| URI: |

Share and export

Available files, --> --> accepted version -->.

Filename: CSCM Review paper_JCLP_authors_copy.pdf

Licence: Creative Commons: Attribution-Noncommercial-No Derivative Works 3.0

View detailed statistics

- Skip to main content

- Accessibility information

- Enlighten Enlighten

- Publications

Enlighten Publications

- Latest Additions

- Browse by Author

- Browse by Year

- Browse by Journal

- Browse by Research Funder Name

- Browse by Colleges/Schools

- Open Access

In this section

Circular supply chain management: A definition and structured literature review

) (doi: 10.1016/j.jclepro.2019.04.303 )

Full text not currently available from Enlighten.

Circular economy is increasingly recognized as a better alternative to the dominant linear (take, make, and dispose) economic model. Circular Supply Chain Management (CSCM), which integrates the philosophy of the circular economy into supply chain management, offers a new and compelling perspective to the supply chain sustainability domain. Consequently, there is increasing research interest. However, a review of the extant literature shows that a comprehensive integrated view of CSCM is still absent in the extant literature. This prohibits a clear distinction compared to other supply chain sustainability concepts and hinders further progress of the field. In response, this research first classifies various terminologies related to supply chain sustainability and conceptualizes a unifying definition of CSCM. Using this definition as a base, it then conducts a structured literature review of 261 research articles on the current state of CSCM research. Based on the review results, the researchers call for further studies in the following directions that are important but received little or no attention: design for circularity, procurement and CSCM, biodegradable packaging, circular supply chain collaboration and coordination, drivers and barriers of CSCM, circular consumption, product liabilities and producer's responsibility, and technologies and CSCM.

| Item Type: | Articles |

|---|---|

| Additional Information: | This work was partially supported by National Natural Science Foundation of China (51875251, 71872072), Natural Science Foundation of Guangdong (China) (2016A030311041), Blue Fire Project (Huizhou) Industry-University-Research Joint Innovation Fund of Ministry of Education (China) (CXZJHZ201722), the Fundamental Research Funds for the Central Universities (China) (11618401). |

| Status: | Published |

| Refereed: | Yes |

| Glasgow Author(s) Enlighten ID: | |

| Authors: | Farooque, M., , Thürer, M., Qu, T., and Huisingh, D. |

| College/School: | |

| Journal Name: | |

| Publisher: | Elsevier |

| ISSN: | 0959-6526 |

| ISSN (Online): | 1879-1786 |

| Published Online: | 26 April 2019 |

| Related URLs: |

University Staff: Request a correction | Enlighten Editors: Update this record

| ID Code: | 306412 |

|---|---|

| Depositing User: | |

| Datestamp: | 15 Jan 2024 11:02 |

| Last Modified: | 15 Jan 2024 11:02 |

| Date of acceptance: | 23 April 2019 |

| Date of first online publication: | 26 April 2019 |

- Privacy Notice

- Accessibility Statement

The University of Glasgow is a registered Scottish charity: Registration Number SC004401

- DOI: 10.1016/J.JCLEPRO.2019.04.303

- Corpus ID: 159417811

Circular supply chain management: A definition and structured literature review

- Muhammad Farooque , A. Zhang , +2 authors D. Huisingh

- Published in Journal of Cleaner Production 1 August 2019

- Environmental Science, Business

Figures and Tables from this paper

407 Citations

Circular economy and supply chains: definitions, conceptualizations, and research agenda of the circular supply chain framework.

- Highly Influenced

- 19 Excerpts

Circular supply chain management: A state-of-art review and future opportunities

Main dimensions in the building of the circular supply chain: a literature review, interdisciplinary challenges in the circular supply chains: a systematic literature review., sustainable supply chain management in the route for a circular economy: an integrative literature review, circular supply chain management: a bibliometric analysis-based literature review, circular supply chain: literature review and theoretical framework, circular supply chain management and circular economy: a conceptual model, multi-dimensional circular supply chain management: a comparative review of the state-of-the-art practices and research, supply chain management for circular economy: conceptual framework and research agenda, 342 references, green supply-chain management: a state-of-the-art literature review.

- Highly Influential

- 11 Excerpts

From a literature review to a conceptual framework for sustainable supply chain management

Supply chain configurations in the circular economy: a systematic literature review, sustainable supply chain management: evolution and future directions, sustainable supply chain - a review of research fields and a proposition of future exploration, challenges in supply chain redesign for the circular economy: a literature review and a multiple case study, a review of sustainable supply chain management practices in canada, world class sustainable supply chain management: critical review and further research directions, a framework of sustainable supply chain management: moving toward new theory, theories in sustainable supply chain management: a structured literature review, related papers.

Showing 1 through 3 of 0 Related Papers

Published in Journal of Cleaner Production 2019

Muhammad Farooque A. Zhang M. Thürer T. Qu D. Huisingh

To read this content please select one of the options below:

Please note you do not have access to teaching notes, circular supply chain management: a bibliometric analysis-based literature review.

The International Journal of Logistics Management

ISSN : 0957-4093

Article publication date: 20 January 2023

Issue publication date: 28 April 2023

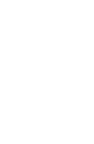

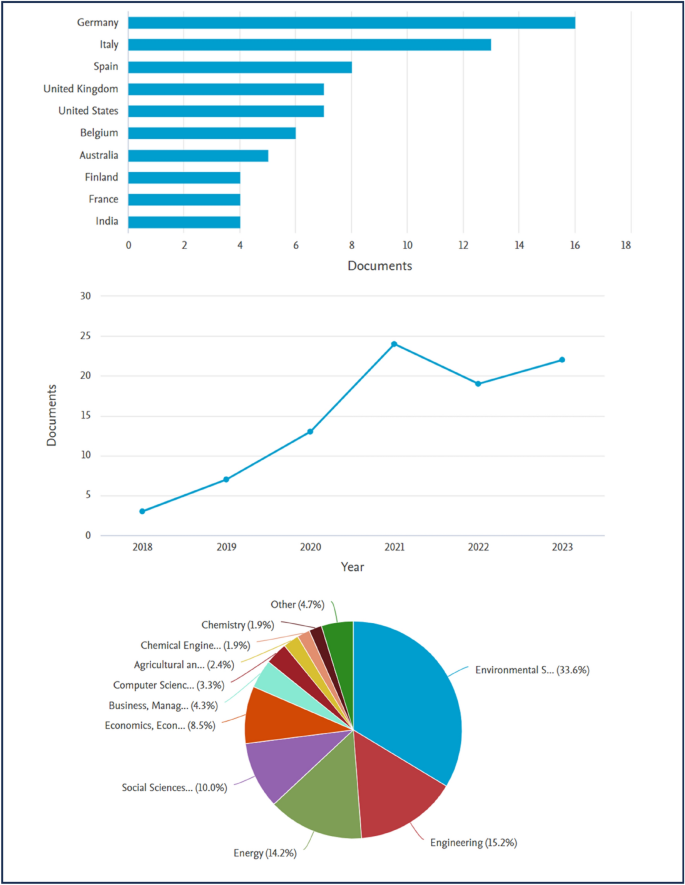

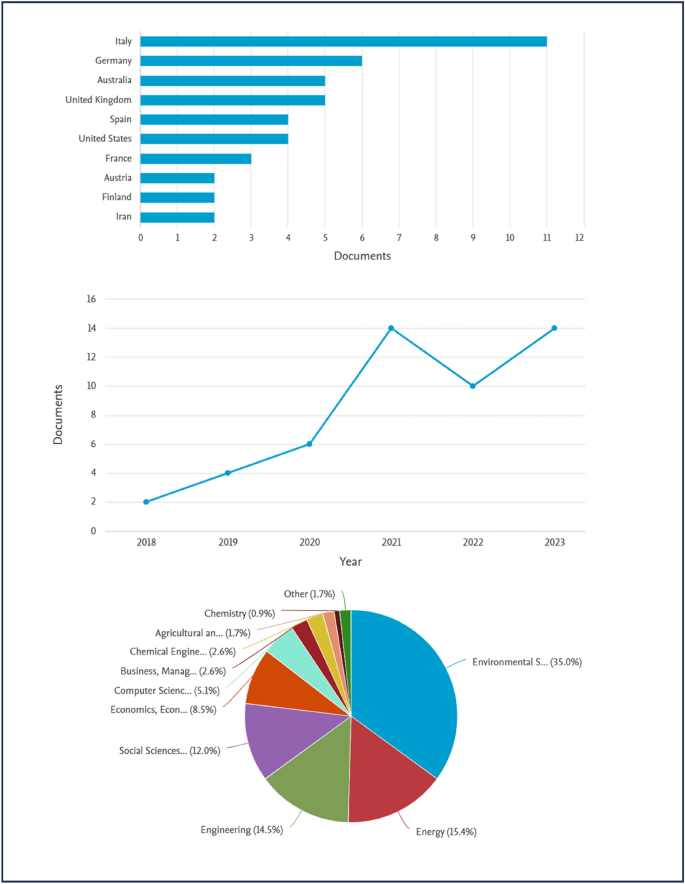

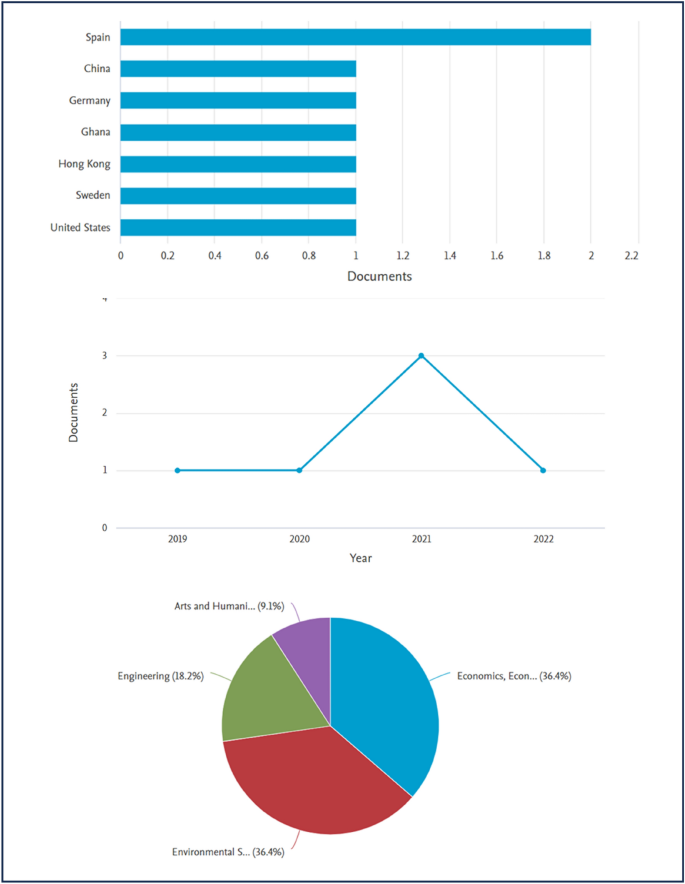

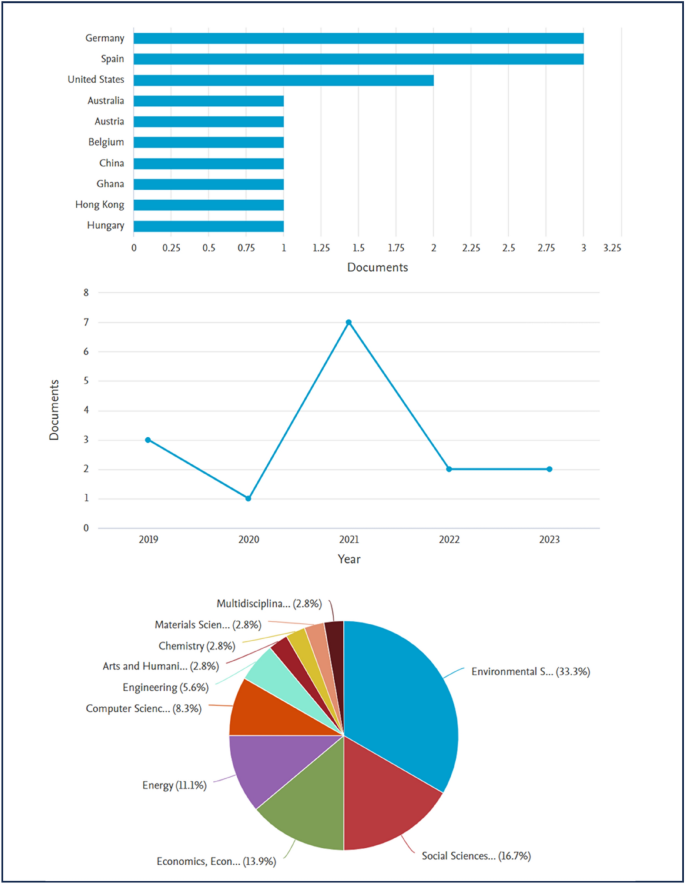

Supply chain management (SCM) research has contributed to the transition to a circular economy (CE). Still, confusions exist on the related terms, and no review has mapped out the development trends in the domain. This research clarifies the boundaries of the relevant concepts. Then, it conducts a comprehensive review of the circular SCM (CSCM) literature and identifies opportunities for future research.

Design/methodology/approach

Using relevant keywords, 1,130 journal articles published in December 31, 2021 were identified. Unlike the published reviews, which mainly relied on content analysis, this review uses bibliometric analysis tools, including citation analysis, co-citation analysis and cluster analysis. The review identifies general trends, influential researchers, high-impact publications, citation patterns and established and emergent research themes.

The extant CSCM literature includes five prominent clusters: (1) reverse channel optimization; (2) CSCM review and empirical studies; (3) closed-loop supply chain (CLSC) and consumers; (4) CLSC and inventory management and (5) CLSC and reverse logistics (RL). Significant research gaps exist in the use of secondary and longitudinal data, a wider range of theories, mixed-methods, multi-method, action research and behavioral experiment. The least researched topics include zero waste, industrial symbiosis, circular product design, sourcing and supply management and reuse.

Originality/value

This is the first bibliometric analysis-based literature review on CSCM. It clarifies the interrelated supply chain sustainability terms and thus reduces related confusion. It offers insights into the patterns in the CSCM literature and suggests important research directions.

- Circular economy

- Circular supply chain management

- Closed-loop supply chain management

- Sustainable supply chain management

- Literature review

Acknowledgements

Funding: Dr. Abraham Zhang acknowledges partial funding support from the 2020 Endeavour Fund, Ministry of Business, Innovation and Employment of New Zealand (Project title: Āmiomio Aotearoa - A Circular Economy for the Wellbeing of New Zealand).

Zhang, A. , Duong, L. , Seuring, S. and Hartley, J.L. (2023), "Circular supply chain management: a bibliometric analysis-based literature review", The International Journal of Logistics Management , Vol. 34 No. 3, pp. 847-872. https://doi.org/10.1108/IJLM-04-2022-0199

Emerald Publishing Limited

Copyright © 2023, Emerald Publishing Limited

Related articles

All feedback is valuable.

Please share your general feedback

Report an issue or find answers to frequently asked questions

Contact Customer Support

Circular supply chain management: A definition and structured literature review

Chat with Paper: Save time, read 10X faster with AI

Citation Count

Barriers to smart waste management for a circular economy in China

Circular supply chain management: a state-of-art review and future opportunities, blockchain-based life cycle assessment: an implementation framework and system architecture, a typology of circular start-ups: an analysis of 128 circular business models, digital supply chain model in industry 4.0, content analysis: an introduction to its methodology, from a literature review to a conceptual framework for sustainable supply chain management, green supply‐chain management: a state‐of‐the‐art literature review, a review on circular economy: the expected transition to a balanced interplay of environmental and economic systems, a framework of sustainable supply chain management: moving toward new theory, related papers (5), frequently asked questions (10), q1. what contributions have the authors mentioned in the paper "circular supply chain management: a definition and structured literature review" .

In response, this research first classifies various terminologies related to supply chain sustainability and conceptualizes a unifying definition of CSCM. Using this definition as a base, it then conducts a structured literature review of 261 research articles on the current state of CSCM research. Based on the review results, the researchers call for further studies in the following directions that are important but received little or no attention: design for circularity, procurement and CSCM, biodegradable packaging, circular supply chain collaboration and coordination, drivers and barriers of CSCM, circular consumption, product liabilities and producer ’ s responsibility, and technologies and CSCM.

Q2. What have the authors stated for future works in "Circular supply chain management: a definition and structured literature review" ?

Based on the review results, Table 5 outlines the importance of each research direction, the extent of relevant knowledge gap, potential impact of conducting research in the research direction, and the urgency for further research. Packaging solutions based on biodegradable materials deserve much future research and investments for enhancing the rate of transition to CEs. Given that many consumers are unwilling to return used products ( van Weelden et al., 2016 ), it is important to study strategies and incentives for changing consumer behaviors to support the cause of circularity. Future research is needed to investigate the feasibility and effectiveness of an extended producer responsibility legislation ( King et al., 2006 ; Zhu et al., 2010 ) to hold producers accountable for their products, even long after a sale to end customers.

Q3. What are the main characteristics of the PSSs?

The PSSs exemplify a range of business models from being ‘product orientatedwith a few extra services included’ to more ‘result-oriented’ services with no predeterminedproduct involved (Hobson, 2016; Yang et al., 2018).

Q4. What is the role of steel scrap in the recycling process?

Giventhe recyclable nature of the material itself, steel scrap is an important resource for steelmakingwhich can be recovered from products (Wübbeke and Heroth, 2014; Broadbent, 2016; Dienerand Tillman, 2016).

Q5. What is the definition of green logistics?

‘Green logistics’ is recognized as producing and distributing goodsin a sustainable way, taking account of environmental and social factors.

Q6. What is the main factor that influences consumers’ motivations regarding mobile phones consumption in Austria?

Wieser and Tröger (2016) studied consumers’motivations regarding mobile phones consumption in Austria using dimensions such as thetiming of replacement, repair, and reuse of mobile phones.

Q7. What are the frequently used methods in different studies?

Conceptual/Theoretical model (43 papers) and Literature review (38) are the second and thirdmost frequently used methods in different studies, respectively.

Q8. What did the authors do to reduce subjectivity?

Tominimize subjectivity, the authors: (i) cross-checked results; and, (ii) conducted regularmeetings among themselves to resolve any emerging inconsistencies in interpreting the results.

Q9. What are the possible remedies to the lack of metal recycling?

On the other hand, betterregulations and effective use of taxation, encouraging R&D in metals, establishment ofextended producer responsibilities systems (Mo et al., 2009; Gumley, 2014) and use of robustforecasting models (Gauffin et al., 2016) were discussed as the possible remedies to the lackof metal recycling.

Q10. What is the definition of sustainable supply chain management?

this closely mirrors the definition of sustainable supply chain management:“the management of material, information and capital flows as well as cooperation amongcompanies along the supply chain while taking goals from all three dimensions of sustainabledevelopment, i.e., economic, environmental and social, into account which are derived fromcustomer and stakeholder requirements” (Seuring and Müller, 2008, p.1700).

Trending Questions (1)

Circular Supply Chain Management (CSCM), which integrates the philosophy of the circular economy into supply chain management, offers a new and compelling perspective to the supply chain sustainability domain.

Literature review on circular supply chain management

- Article contents

- Figures & tables

- Supplementary Data

- Peer Review

- Reprints and Permissions

- Cite Icon Cite

- Search Site

Ishaan Dey , Gunjan Soni , Gaurav Kumar Badhotiya; Literature review on circular supply chain management. AIP Conf. Proc. 8 May 2023; 2521 (1): 040014. https://doi.org/10.1063/5.0113696

Download citation file:

- Ris (Zotero)

- Reference Manager

The circular economy is becoming acknowledged as a superior alternative to the current linear economic paradigm (take, make, and dispose). A fresh and convincing approach offers the supply chain area with durability, which includes the idea of the circular economy in supply chain management. Consequently, research interest is increasing. A survey of current literature indicates nevertheless that there is currently no complete integrated CSCM perspective of the available material. This prohibits a clear difference and prevents future advances in the sector in comparison to other sustainable supply chain approaches. This research also distinguishes distinct terms related to the supply chain robustness and conceptualizes a common meaning of the CSCM. The conclusion shows that CSCM development needs enough opening and room for exploration using sophisticated quantitative analysis method, highly developed techniques of optimization, automatic multiple criteria judgment call procedures, and professional algorithms. CSCM research must further uncover performance indicators, barriers, new circular business models and creative structures. This study will also encourage scholars to uncover new aspects in the CSCM area.

Sign in via your Institution

Citing articles via, publish with us - request a quote.

Sign up for alerts

- Online ISSN 1551-7616

- Print ISSN 0094-243X

- For Researchers

- For Librarians

- For Advertisers

- Our Publishing Partners

- Physics Today

- Conference Proceedings

- Special Topics

pubs.aip.org

- Privacy Policy

- Terms of Use

Connect with AIP Publishing

This feature is available to subscribers only.

Sign In or Create an Account

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Circular supply chain management: A definition and structured literature review

2019, Journal of Cleaner Production

Related Papers

Sustainability

Monrudee Theeraworawit

Since the mid-2010s, the circular economy has emerged as a key conceptual lever in corporate efforts to achieve greater environmental sustainability. Corporations have increasingly drawn upon the circular economy perspective in efforts to rethink sustainable supply chain management practices. This new corporate approach to sustainable supply chain management is evident in an emerging literature that has yet to be fully documented. In this systematic review of research, bibliometric methods were applied to a database of 709 Scopus-indexed documents. Author co-citation analysis identified four schools of thought comprising the intellectual structure of this literature: Sustainable Production and Environmental Management, Sustainable Supply Chain Management, Reverse Supply Chain Management, and Circular Economy. Synthesis of these themes suggests that the adoption of a circular economy perspective is transforming sustainable supply chain management in two important ways. First, this pe...

Patricia Guarnieri

Sustainable supply chain management (SSCM) considers social, environmental, and economic dimensions of sustainability. In the context of the pandemic, organizations must face consequences striking the wider dimensions of sustainability. Thus, after the COVID-19 pandemic, how will the value chains collaborate for the transition from a traditional (linear) to a Circular Economy? From this question, in this paper, we analyze the international papers that connect sustainable supply chain management (SSCM) with circular economy (CE). We conducted an Integrative Literature Review based on the Web of Science and Scopus databases from 2010 to 2020, using the Methodi Ordinatio protocol to classify the papers. The 37 best-ranked papers were analyzed thoroughly. The results show the prominent authors, institutions, the network relationship between authors, the evolution of publications, and the leading journals. The content of these articles was categorized and discussed about the changes in t...

Brazilian journal of operations & production management

Jeniffer Nadae

Goal: To analyze the publications on circular economy and supply chain using a systematic review of the literature and bibliometric analysis, the study was designed to answer the question: How is the international scientific production about Circular Economy and Supply Chain characterized? For such an answer it was found that the first published article was on the subject date from 2006 and 2013 there was a steady increase in the number of publications. Many publications mentioned the use of CE in the supply chain through the management of the green supply chain. The country with more publications about the area in the United Kingdom with 19,1% of papers. Moreover, publications are generally about IT product and service supply chains. Design/Methodology/Approach: Systematic literature review based on bibliometric theory and social network analysis, linking Circular Economy and Supply Chain. Results: The articles do not point to studies on a specific supply chain, but only stress the...

Resources Conservation and Recycling

Jos Van Hillegersberg

Journal of Theoretical and Applied Electronic Commerce Research

pooja trivedi

Circular Supply Chain Management (CSCM) incorporates the economy concept into supply chain concepts, which gives the supply chain sustainability domain an innovative and convincing viewpoint. The challenging factors in the circular economy are cooperation, trust, and transparency. Therefore, to achieve sustainable results, collaboration, and openness between organizations within networks and value chains are required. This paper explores the sustainability success using the Sustainable Circular Business Model (SCBM) to incorporate the principle at an operational level and suggest a structure for combining Circular Business Model (CBM) and CSCM for sustainable growth. The proposed structure shows how various circular business structures power the global supply chain in multiple loops. The circular business models differ according to the difficulty of the Circular Supply Chain (CSC) and the value proposition. Proposed SCBM shows that circular market and supply chain aid in reaching go...

Sri Sudha Vijay Keshav Kolla

The concept of the circular economy (CE) is receiving encouraging attention among scholars and practitioners, as a convenient solution to move away from the linear economy concept without neglecting the goals of sustainable development. The main goals of the CE are the closing of resource loops and the keeping of resources in the system for as long as possible at the highest utility level. However, as a result of the lack of internationally accepted definitions of the CE and several unsolved barriers, an excessive and inconsistent number of different CE applications exist. Most fields are mainly focusing on making a linear system circular instead of applying the CE principles in a holistic way. This paper presents a strategy to close the mentioned inconsistency gap, by contrasting currently discussed CE barriers and goals and thereof deriving two areas with a need for action (1. identifying the needed collection, sorting, and recovery infrastructure, and 2. developing circular produ...

International Journal of Production Research

Gianmarco Bressanelli

Despite companies face several challenges when redesigning their supply chain for the Circular Economy, the literature lacks a systematisation of such challenges and of the ways to overcome them. Through a systematic literature review, this paper identifies and systematises 24 challenges that may hamper a supply chain redesign for the Circular Economy. Sixteen among these challenges are well known from research in related topics. On the contrary, the remaining eight are relatively new or take a different relevance within the Circular Economy context. A multiple case study in the household appliance supply chain is carried out, to explore how these challenges appear in practice and how companies may tackle them. The cases analysed involve actors at different supply chain levels, and findings suggest that a great degree of vertical integration by one actor in the supply chain is not a necessary condition for Circular Economy implementation. The empirical study, in conjunction with the literature analysis, leads to the development of a framework linking the challenges to specific levers that companies may pursue to overcome them. The framework can be seen as a reference for managers undertaking the path towards Circular Economy

Production Planning & Control

Luciano Batista

Frontiers in Sustainability

Valentina G H Schmitt

The circular economy can protect companies against resource scarcity and price volatility, creating opportunities for the development of innovative and efficient methods of production and consumption. It also involves the creation of local jobs, opportunities for social integration, energy savings and the prevention of irreversible damage, as a result of consuming resources faster than the Earth's resilience. https://www.frontiersin.org/research-topics/20122/circular-business-models-and-strategies-the-key-to-sustainable-business-and-innovative-supply-chai 1/4

Production Planning & Control

Amrik Sohal

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

RELATED PAPERS

Circular Economy and Sustainability

Diego Vazquez-Brust

SUNIL K LUTHRA

Proceedings of the 22nd Cambridge International Manufacturing Symposium

Fabio F A Pollice

The Asian Institute of Research

shaharia pavel

Francesco Di Maio

Madushan madhava Jayalath

Yiğit Kazançoğlu

Journal of Cleaner Production

Steve Evans

Európai Tükör

Katalin Erdei-Derschner

David João Camocho

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Examining the response to covid-19 in logistics and supply chain processes: insights from a state-of-the-art literature review and case study analysis.

1. Introduction

- RQ1 (scientific): How have researchers studied the impact of COVID-19 on logistics and supply chain processes? Which industrial sectors were mostly studied and why? Which additional topics can be related to COVID-19 and logistics/supply chain?

- RQ2 (practical): What effects of COVID-19 on logistics and supply chain processes were experienced by companies?

2. Materials and Methods

2.1. systematic literature review, 2.1.1. sample creation, 2.1.2. descriptive analyses, 2.1.3. paper classification.

- Macro theme: sustainability, resilience, risk, information technology, economics, performance, planning and food security. This classification represents paper’s core topic.

- Industrial sector: aerospace, agri-food, apparel, automotive, construction, e-commerce, electronic, energy, fast-moving consumer goods, food, healthcare, logistics, manufacturing and service.

- Data collection method: questionnaire/interview, third-party sources or case study. This classification represents the method used by the authors to collect the data useful to their study.

- Research method: statistical, decision-making, simulation, empirical, literature review or economic. This category describes the tool used by the authors to conduct the study and reach the related goals.

- Specific method, e.g., descriptive statistics, structural equation modeling (SEM), multi-criteria decision making (MCDM), etc.; this feature describes more accurately the type of work carried out by the authors and the tools used.

- Country: it reflects the geographical area in which the study was carried out, in terms, for instance, of the country in which a sample of people has been interviewed or where empirical data were collected, or where the simulation was set. This method of classification, although more elaborated, was preferred over traditional approaches, in which the country of the study is defined based merely on the affiliation of the first author of the paper, because the exact knowledge of the country in which the study was carried out is, for sure, a more representative source of information about the research. This is true in general, but it is even more important for this subject matter, as the management of the COVID-19 pandemic was made on a country or regional basis, with significant differences from country to country; knowing the exact location of the study helps in better interpreting the research outcomes. Possible entries in this field also include “multiple countries” and “not specified”, with the obvious meanings of the terms.

2.1.4. Cross-Analyses

2.1.5. interrelated aspects, 2.2. case study, 2.2.1. data collection.

- Economic data: some key economic data were retrieved from the company’s balance sheet, from 2019 up to the latest available document, which refers to 2022.

- Organizational data: these data describe changes in the operational, decision-making and business structure of the company in terms, e.g., of number of employees hired, number of drivers, etc.

- The related data were collected and elaborated between July and September 2023.

2.2.2. Survey Phase

2.2.3. analysis and summary, 3. results—systematic literature review, 3.1. descriptive statistics, 3.2. common classification fields, 3.2.1. macro theme, 3.2.2. industrial sector, 3.2.3. data collection method, 3.2.4. research method, 3.2.5. country, 3.3. cross-analyses, 3.3.1. macro theme vs. industrial sector, 3.3.2. research method vs. macro theme, 3.4. interrelated aspects, 4. results—case study, 4.1. company overview, 4.2. pre-covid-19 period, 4.3. covid-19 period, 4.4. post-covid-19 period, 4.5. analysis and summary.

- Strengths : at present, Company A benefits from a robust network of relationships with customers and suppliers (e.g., drivers), which was leveraged during the pandemic period to provide a rapid response to the increased request by the consumers. The company has also leveraged the usage of digital technologies, which made logistics activities more efficient and, again, allowed the company to respond to consumer demand in the pandemic period.

- Weaknesses : Company A has suffered from low economic results, in particular in the post-COVID-19 period, mainly due to the high production costs. Efforts must be made by the company to reduce expenses. At the same time, however, the service level, in terms of delivery lead time or on-time delivery, should be safeguarded.

- Opportunities : the growth of e-commerce, experienced in the COVID-19 period but expected to last over time, creates opportunities for increasing the volume of items handled by Company A. Indeed, the survey phase demonstrated that the company’s consumers have shifted towards the usage of online sales; hence, the company could consider investing in this area to increase its market share. By leveraging the e-commerce logistics and diversifying service, expansions could also be possible at an international level. Even if the company has already embraced the implementation of digital technologies, some emerging technologies (e.g., drones or advanced traceability systems) could also be introduced for further improving the logistics efficiency. Finally, sustainability is another opportunity to be leveraged, because of the current push towards the adoption of environmental-friendly logistics solutions. Examples of those solutions include a reduction in CO 2 emissions, and the usage of electric vehicles or zero-impact materials.

- Threats : the growth of e-commerce can be seen as an opportunity, but because many logistics companies have already entered this field, the sector is characterized by very high competition, which could limit the market share of Company A; this could instead be seen as a threat needing to be properly managed. Another threat comes from the increased cost of fuel, which, for sure, for a logistics company plays an important role in determining the cost of the transport activities (also, having previously observed that the company suffered from a limited revenue in recent years). This factor could further push towards the adoption of environmentally friendly transport modes (e.g., electric vehicles), which have been previously mentioned as an opportunity for leveraging in the logistics sector.

5. Conclusions

5.1. answer to the research questions, 5.2. scientific and practical implications, 5.3. suggestions for future research directions, author contributions, institutional review board statement, informed consent statement, data availability statement, conflicts of interest.

- Christopher, M. Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service Financial Times ; Pitman Publishing: London, UK, 1998; ISBN 0 273 63049 0. [ Google Scholar ]

- Gechevski, D.; Kochov, A.; Popovska-Vasilevska, S.; Polenakovik, R.; Donev, V. Reverse Logistics and Green Logistics Way to Improving the Environmental Sustainability. Acta Tech. Corviniensis-Bull. Eng. 2016 , 9 , 63. [ Google Scholar ]

- Mbang, A. A New Introduction to Supply Chains and Supply Chain Management: Definitions and Theories Perspective. Int. Bus. Res. 2011 , 5 , 194–207. [ Google Scholar ] [ CrossRef ]

- Jones, T.C.; Riley, D.W. Using Inventory for Competitive Advantage through Supply Chain Management. Int. J. Phys. Distrib. Mater. Manag. 1985 , 15 , 16–26. [ Google Scholar ] [ CrossRef ]

- Monczka, R.M.; Trent, R.J.; Handfield, R.B. Purchasing and Supply Chain Management ; South Western Educational Publishing: Natorp Blvd Cincinnati, OH, USA, 2002; ISBN 0-324-02315-4. [ Google Scholar ]

- Belhadi, D.; Peiffer-Smadja, N.; Lescure, F.-X.; Yazdanpanah, Y.; Mentré, F.; Laouénan, C. A Brief Review of Antiviral Drugs Evaluated in Registered Clinical Trials for COVID-19. MedRxiv 2020 . [ Google Scholar ] [ CrossRef ]

- Shen, Z.; Sun, Y. Strengthening Supply Chain Resilience during COVID-19: A Case Study of JD.Com. J. Oper. Manag. 2021 , 69 , 359–383. [ Google Scholar ] [ CrossRef ]

- Dohale, V.; Verma, P.; Gunasekaran, A.; Ambilkar, P. COVID-19 and Supply Chain Risk Mitigation: A Case Study from India. Int. J. Logist. Manag. 2023 , 34 , 417–442. [ Google Scholar ] [ CrossRef ]

- Mishra, P.K. COVID-19, Black Swan Events and the Future of Disaster Risk Management in India. Prog. Disaster Sci. 2020 , 8 , 100137. [ Google Scholar ] [ CrossRef ]

- Badhotiya, G.K.; Soni, G.; Jain, V.; Joshi, R.; Mittal, S. Assessing Supply Chain Resilience to the Outbreak of COVID-19 in Indian Manufacturing Firms. Oper. Manag. Res. 2022 , 15 , 1161–1180. [ Google Scholar ] [ CrossRef ]

- Mahmoud, M.A.; Mahmoud, A.; Abubakar, S.L.; Garba, A.S.; Daneji, B.A. COVID-19 Operational Disruption and SMEs’ Performance: The Moderating Role of Disruption Orientation and Government Support. Benchmark. Int. J. 2022 , 29 , 2641–2664. [ Google Scholar ] [ CrossRef ]

- Aldrighetti, R.; Battini, D.; Ivanov, D. Increasing Supply Chain Resilience through Efficient Redundancy Allocation: A Risk-Averse Mathematical Model. Ifac-papersonline 2021 , 54 , 1011–1016. [ Google Scholar ]

- Tang, O.; Nurmaya Musa, S. Identifying Risk Issues and Research Advancements in Supply Chain Risk Management. Int. J. Prod. Econ. 2011 , 133 , 25–34. [ Google Scholar ] [ CrossRef ]

- Rinaldi, M.; Murino, T.; Gebennini, E.; Morea, D.; Bottani, E. A Literature Review on Quantitative Models for Supply Chain Risk Management: Can They Be Applied to Pandemic Disruptions? Comput. Ind. Eng. 2022 , 170 , 108329. [ Google Scholar ] [ CrossRef ]

- Corallo, A.; Lazoi, M.; Lezzi, M.; Luperto, A. Cybersecurity Awareness in the Context of the Industrial Internet of Things: A Systematic Literature Review. Comput. Ind. 2022 , 137 , 103614. [ Google Scholar ] [ CrossRef ]

- Rinaldi, M.; Bottani, E. How Did COVID-19 Affect Logistics and Supply Chain Processes? Immediate, Short and Medium-Term Evidence from Some Industrial Fields of Italy. Int. J. Prod. Econ. 2023 , 262 , 108915. [ Google Scholar ] [ CrossRef ]

- Chowdhury, P.; Paul, S.K.; Kaisar, S.; Moktadir, M.A. COVID-19 pandemic related supply chain studies: A systematic review. Transp. Res. Part E—Logist. Transp. Rev. 2021 , 148 , 102271. [ Google Scholar ] [ CrossRef ]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning supply chains using blockchain-enabled circular economy and COVID-19 experiences. Sustain. Prod. Consum. 2021 , 27 , 10–22. [ Google Scholar ] [ CrossRef ]

- Kraus, S.; Clauss, T.; Breier, M.; Gast, J.; Zardini, A.; Tiberius, V. The economics of COVID-19: Initial empirical evidence on how family firms in five European countries cope with the corona crisis. Int. J. Entrep. Behav. Res. 2020 , 26 , 1067–1092. [ Google Scholar ] [ CrossRef ]

- De Vet, J.M.; Nigohosyan, D.; Ferrer, J.N.; Gross, A.K.; Kuehl, S.; Flickenschild, M. Impacts of the COVID-19 Pandemic on EU Industries. 2021. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2021/662903/IPOL_STU(2021)662903_EN.pdf (accessed on 29 April 2024).

- Manuj, I.; Mentzer, J.T. Global Supply Chain Risk Management. J. Bus. Logist. 2008 , 29 , 133–155. [ Google Scholar ] [ CrossRef ]

- Ali, I.; Golgeci, I.; Arslan, A. Achieving Resilience through Knowledge Management Practices and Risk Management Culture in Agri-Food Supply Chains. Supply Chain. Manag. Int. J. 2023 , 28 , 284–299. [ Google Scholar ] [ CrossRef ]

- Madhavika, N.; Jayasinghe, N.; Ehalapitiya, S.; Wickramage, T.; Fernando, D.; Jayasinghe, V. Operationalizing Resilience through Collaboration: The Case of Sri Lankan Tea Supply Chain during Covid-19. Qual. Quant. 2023 , 57 , 2981–3018. [ Google Scholar ] [ CrossRef ]

- Aman, S.; Seuring, S. Analysing Developing Countries Approaches of Supply Chain Resilience to COVID-19. Int. J. Logist. Manag. 2023 , 34 , 909–934. [ Google Scholar ] [ CrossRef ]

- Maharjan, R.; Kato, H. Resilient Supply Chain Network Design: A Systematic Literature Review. Transp. Rev. 2022 , 42 , 739–761. [ Google Scholar ] [ CrossRef ]

- Zidi, S.; Hamani, N.; Kermad, L. Antecedents and Enablers of Supply Chain Reconfigurability and Their Effects on Performance. Int. J. Adv. Manuf. Technol. 2022 , 120 , 3027–3043. [ Google Scholar ] [ CrossRef ]

- Nabipour, M.; Ülkü, M.A. On Deploying Blockchain Technologies in Supply Chain Strategies and the COVID-19 Pandemic: A Systematic Literature Review and Research Outlook. Sustainability 2021 , 13 , 10566. [ Google Scholar ] [ CrossRef ]

- Rokicki, T.; Bórawski, P.; Bełdycka-Bórawska, A.; Szeberényi, A.; Perkowska, A. Changes in Logistics Activities in Poland as a Result of the COVID-19 Pandemic. Sustainability 2022 , 14 , 10303. [ Google Scholar ] [ CrossRef ]

- Figura, J.; Gądek-Hawlena, T. The Impact of the COVID-19 Pandemic on the Development of Electromobility in Poland. The Perspective of Companies in the Transport-Shipping-Logistics Sector: A Case Study. Energies 2022 , 15 , 1461. [ Google Scholar ] [ CrossRef ]

- Baldrighi, E.; Monferdini, L.; Bottani, E. The Response to COVID-19 in Logistics and Supply Chain Processes: Evidence from a Review of the Literature. In Proceedings of the International Conference on Harbour, Maritime and Multimodal Logistics Modelling and Simulation, Athens, Greece, 18–20 September 2023. [ Google Scholar ]

- Bottani, E.; Monferdini, L. Studies related to Covid-19 in logistics and supply chain processes (2021–2023). Mendeley Data 2024 , V1. [ Google Scholar ] [ CrossRef ]

- Kesmodel, U.S. Cross-Sectional Studies—What Are They Good For? Acta Obstet. Gynecol. Scand. 2018 , 97 , 388–393. [ Google Scholar ] [ CrossRef ]

- Thompson, M.L.; Myers, J.; Kriebel, D. Prevalence Odds Ratio or Prevalence Ratio in the Analysis of Cross Sectional Data: What Is to Be Done? Occup. Environ. Med. 1998 , 55 , 272–277. [ Google Scholar ] [ CrossRef ]

- Robson, C. Real World Research: A Resource for Social Scientists and Practitioner-Researchers ; Blackwell Publishing: Hoboken, NJ, USA, 1993; ISBN 978-0-631-17689-3. [ Google Scholar ]

- Yin, R. Case Studies. Int. Encycl. Soc. Behav. Sci. 2015 , 2 , 194–201. [ Google Scholar ] [ CrossRef ]

- Wohlin, C. Case Study Research in Software Engineering—It Is a Case, and It Is a Study, but Is It a Case Study? Inf. Softw. Technol. 2021 , 133 , 106514. [ Google Scholar ] [ CrossRef ]

- Grabot, B.; Vallespir, B.; Samuel, G.; Bouras, A.; Kiritsis, D. Advances in Production Management Systems: Innovative and Knowledge-Based Production Management in a Global-Local World: IFIP WG 5.7 International Conference, APMS 2014, Ajaccio, France, 20–24 September 2014, Proceedings, Part II ; Springer: Berlin/Heidelberg, Germany, 2014; Volume 439, ISBN 3-662-44736-3. [ Google Scholar ]

- Alicke, K.; Azcue, X.; Barriball, E.; Supply-Chain Recovery in Coronavirus Times—Plan for Now and the Future. McKinsey & Company. 2020. Available online: https://www.mckinsey.com (accessed on 29 April 2024).

- Ivanov, D. Supply Chain Viability and the COVID-19 Pandemic: A Conceptual and Formal Generalisation of Four Major Adaptation Strategies. Int. J. Prod. Res. 2021 , 59 , 3535–3552. [ Google Scholar ] [ CrossRef ]

- Adobor, H.; McMullen, R.S. Supply Chain Resilience: A Dynamic and Multidimensional Approach. Int. J. Logist. Manag. 2018 , 29 , 1451–1471. [ Google Scholar ] [ CrossRef ]

- Singh, C.S.; Soni, G.; Badhotiya, G.K. Performance Indicators for Supply Chain Resilience: Review and Conceptual Framework. J. Ind. Eng. Int. 2019 , 15 , 105–117. [ Google Scholar ] [ CrossRef ]

- Mohammed, A.; Jabbour, A.B.L.D.S.; Diabat, A. COVID-19 Pandemic Disruption: A Matter of Building Companies’ Internal and External Resilience. Int. J. Prod. Res. 2023 , 61 , 2716–2737. [ Google Scholar ] [ CrossRef ]

- El Khoury, R.; Nasrallah, N.; Atayah, O.F.; Dhiaf, M.M.; Frederico, G.F. The Impact of Green Supply Chain Management Practices on Environmental Performance during COVID-19 Period: The Case of Discretionary Companies in the G-20 Countries. Benchmark. Int. J. 2022 . ahead of print . [ Google Scholar ] [ CrossRef ]

- Sharma, V.; Singh, A.; Rai, S.S. Disruptions in Sourcing and Distribution Practices of Supply Chains Due to COVID-19 Pandemic: A Sustainability Paradigm. J. Glob. Oper. Strateg. Sourc. 2022 , 15 , 235–261. [ Google Scholar ] [ CrossRef ]

- Karmaker, C.L.; Bari, A.B.M.M.; Anam, M.Z.; Ahmed, T.; Ali, S.M.; de Jesus Pacheco, D.A.; Moktadir, M.A. Industry 5.0 Challenges for Post-Pandemic Supply Chain Sustainability in an Emerging Economy. Int. J. Prod. Econ. 2023 , 258 , 108806. [ Google Scholar ] [ CrossRef ]

- Paul, A.; Shukla, N.; Trianni, A. Modelling Supply Chain Sustainability Challenges in the Food Processing Sector amid the COVID-19 Outbreak. Socio-Econ. Plan. Sci. 2023 , 87 , 101535. [ Google Scholar ] [ CrossRef ]

- Siuta, K.; Kaszyński, D. The Principal-Agent Problem in Supply Chain Management—The Simulation Based Framework. Control. Cybern. 2021 , 50 , 195–221. [ Google Scholar ] [ CrossRef ]

- Kumar, P.; Singh, S.S.; Pandey, A.K.; Singh, R.K.; Srivastava, P.K.; Kumar, M.; Dubey, S.K.; Sah, U.; Nandan, R.; Singh, S.K.; et al. Multi-Level Impacts of the COVID-19 Lockdown on Agricultural Systems in India: The Case of Uttar Pradesh. Agric. Syst. 2021 , 187 , 103027. [ Google Scholar ] [ CrossRef ]

- Atayah, O.F.; Dhiaf, M.M.; Najaf, K.; Frederico, G.F. Impact of COVID-19 on Financial Performance of Logistics Firms: Evidence from G-20 Countries. J. Glob. Oper. Strateg. Sourc. 2022 , 15 , 172–196. [ Google Scholar ] [ CrossRef ]

- Israfilov, N.; Druzyanova, V.; Ermakova, M.; Sinitsyna, A. Key Directions for Transforming Supply Chain Management in Emerging Markets during the PostCOVID-19 Pandemic Period. Oper. Supply Chain. Manag. 2023 , 16 , 498–508. [ Google Scholar ] [ CrossRef ]

- Dwivedi, A.; Chowdhury, P.; Paul, S.K.; Agrawal, D. Sustaining Circular Economy Practices in Supply Chains during a Global Disruption. Int. J. Logist. Manag. 2023 , 34 , 644–673. [ Google Scholar ] [ CrossRef ]

- Ghadge, D.A.; Er, M.; Ivanov, D.; Chaudhuri, A. Visualisation of Ripple Effect in Supply Chains under Long-Term, Simultaneous Disruptions: A System Dynamics Approach. Int. J. Prod. Res. 2021 , 60 , 1987547. [ Google Scholar ] [ CrossRef ]

- Eldem, B.; Kluczek, A.; Bagiński, J. The COVID-19 Impact on Supply Chain Operations of Automotive Industry: A Case Study of Sustainability 4.0 Based on Sense–Adapt–Transform Framework. Sustainability 2022 , 14 , 5855. [ Google Scholar ] [ CrossRef ]

- Gui, D.; Wang, H.; Yu, M. Risk Assessment of Port Congestion Risk during the COVID-19 Pandemic. J. Mar. Sci. Eng. 2022 , 10 , 150. [ Google Scholar ] [ CrossRef ]

- Brdulak, H.; Brdulak, A. Challenges and Threats Faced in 2020 by International Logistics Companies Operating on the Polish Market. Sustainability 2021 , 13 , 359. [ Google Scholar ] [ CrossRef ]

- Paul, S.K.; Chowdhury, P.; Chowdhury, M.T.; Chakrabortty, R.K.; Moktadir, M.A. Operational Challenges during a Pandemic: An Investigation in the Electronics Industry. Int. J. Logist. Manag. 2023 , 34 , 336–362. [ Google Scholar ] [ CrossRef ]

- Klein, M.; Gutowska, E.; Gutowski, P. Innovations in the T&L (Transport and Logistics) Sector during the COVID-19 Pandemic in Sweden, Germany and Poland. Sustainability 2022 , 14 , 3323. [ Google Scholar ] [ CrossRef ]

- Mishrif, A.; Khan, A. Technology Adoption as Survival Strategy for Small and Medium Enterprises during COVID-19. J. Innov. Entrep. 2023 , 12 , 53. [ Google Scholar ] [ CrossRef ]

- Ishak, S.; Shaharudin, M.R.; Salim, N.A.M.; Zainoddin, A.I.; Deng, Z. The Effect of Supply Chain Adaptive Strategies During the COVID-19 Pandemic on Firm Performance in Malaysia’s Semiconductor Industries. Glob. J. Flex. Syst. Manag. 2023 , 24 , 439–458. [ Google Scholar ] [ CrossRef ]

- Hendijani, R.; Norouzi, M. Supply Chain Integration and Firm Performance in the COVID-19 Era: The Mediating Role of Resilience and Robustness. J. Glob. Oper. Strateg. Sourc. 2023 , 16 , 337–367. [ Google Scholar ] [ CrossRef ]

- Vilko, J.; Hallikas, J. Impact of COVID-19 on Logistics Sector Companies. Int. J. Ind. Eng. Oper. Manag. 2024 , 6 , 25–42. [ Google Scholar ] [ CrossRef ]

- Palouj, M.; Lavaei Adaryani, R.; Alambeigi, A.; Movarej, M.; Safi Sis, Y. Surveying the Impact of the Coronavirus (COVID-19) on the Poultry Supply Chain: A Mixed Methods Study. Food Control 2021 , 126 , 108084. [ Google Scholar ] [ CrossRef ]

- Ali, I.; Arslan, A.; Khan, Z.; Tarba, S. The Role of Industry 4.0 Technologies in Mitigating Supply Chain Disruption: Empirical Evidence From the Australian Food Processing Industry. IEEE Trans. Eng. Manag. 2021 , 71 , 10600–10610. [ Google Scholar ] [ CrossRef ]

- Grigorescu, I.; Popovici, E.-A.; Damian, N.; Dumitraşcu, M.; Sima, M.; Mitrică, B.; Mocanu, I. The Resilience of Sub-Urban Small Farming in Bucharest Metropolitan Area in Response to the COVID-19 Pandemic. Land Use Policy 2022 , 122 , 106351. [ Google Scholar ] [ CrossRef ]

- Perrin, A.; Martin, G. Resilience of French Organic Dairy Cattle Farms and Supply Chains to the Covid-19 Pandemic. Agric. Syst. 2021 , 190 , 103082. [ Google Scholar ] [ CrossRef ]

- Coopmans, I.; Bijttebier, J.; Marchand, F.; Mathijs, E.; Messely, L.; Rogge, E.; Sanders, A.; Wauters, E. COVID-19 Impacts on Flemish Food Supply Chains and Lessons for Agri-Food System Resilience. Agric. Syst. 2021 , 190 , 103136. [ Google Scholar ] [ CrossRef ]

- Ababulgu, N.; Abajobir, N.; Wana, H. The Embarking of COVID-19 and the Perishable Products’ Value Chain in Ethiopia. J. Innov. Entrep. 2022 , 11 , 34. [ Google Scholar ] [ CrossRef ]

- Eileen Bogweh, N.; Lutomia, C. COVID-19 Challenges to Sustainable Food Production and Consumption: Future Lessons for Food Systems in Eastern and Southern Africa from a Gender Lens. Sustain. Prod. Consum. 2021 , 27 , 2208–2220. [ Google Scholar ] [ CrossRef ]

- Igberi, C.; Omenyi, L.; Osuji, E.; Egwu, P.; Ibrahim-olesin, S. Comparative Analysis of the Sustainable Dimensions of Food Security with COVID-19 and Climate Change: A Case Study. Int. J. Adv. Appl. Sci. 2022 , 9 , 9–15. [ Google Scholar ] [ CrossRef ]

- Mugabe, P.A.; Renkamp, T.M.; Rybak, C.; Mbwana, H.; Gordon, C.; Sieber, S.; Löhr, K. Governing COVID-19: Analyzing the Effects of Policy Responses on Food Systems in Tanzania. Agric. Food Secur. 2022 , 11 , 47. [ Google Scholar ] [ CrossRef ]

- Nunes, M.; Abreu, A.; Bagnjuk, J.; Nunes, E.; Saraiva, C. A Strategic Process to Manage Collaborative Risks in Supply Chain Networks (SCN) to Improve Resilience and Sustainability. Sustainability 2022 , 14 , 5237. [ Google Scholar ] [ CrossRef ]

- World Economic Forum (WEF). How to Rebound Stronger from COVID-19—Resilience in Manufacturing and Supply Systems ; World Economic Forum: Cologny, Switzerland, 2020. [ Google Scholar ]

- Zulkiffli, S.N.; Zaidi, N.F.; Padlee, S.F.; Sukri, N.K. Eco-Innovation Capabilities and Sustainable Business Performance during the COVID-19 Pandemic. Sustainability 2022 , 14 , 7525. [ Google Scholar ] [ CrossRef ]

- Moosavi, J.; Hosseini, S. Simulation-Based Assessment of Supply Chain Resilience with Consideration of Recovery Strategies in the COVID-19 Pandemic Context. Comput. Ind. Eng. 2021 , 160 , 107593. [ Google Scholar ] [ CrossRef ]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply Chain Risk Management: A Literature Review. Int. J. Prod. Res. 2015 , 53 , 1030467. [ Google Scholar ] [ CrossRef ]

- Dogbe, C.S.K.; Iddris, F.; Duah, E.; Boateng, P.A.; Kparl, E.M. Analyzing the Health Supply Chain Risks during COVID-19 Pandemic: The Moderating Role of Risk Management. Cogent Bus. Manag. 2023 , 10 , 2281716. [ Google Scholar ] [ CrossRef ]

- Shenoi, V.; Dath, S.; Rajendran, C. Supply Chain Risk Management in Indian Manufacturing Industries: An Empirical Study and a Fuzzy Approach ; Springer Nature Switzerland: Cham, Switzerland, 2021; pp. 107–145. ISBN 978-3-030-69264-3. [ Google Scholar ]

- Jifar, W.; Geneti, G.; Dubale, S. The Impact of COVID-19 on Pharmaceutical Shortages and Supply Disruptions for Non-Communicable Diseases Among Public Hospitals of South West, Oromia, Ethiopia. J. Multidiscip. Healthc. 2022 , 15 , 1933–1943. [ Google Scholar ] [ CrossRef ]

- Goodarzian, F.; Taleizadeh, A.; Ghasemi, P.; Abraham, A. An Integrated Sustainable Medical Supply Chain Network during COVID-19 ; Elsevier: Amsterdam, The Netherlands, 2021; Volume 100. [ Google Scholar ]

- Bump, J.B.; Friberg, P.; Harper, D.R. International Collaboration and Covid-19: What Are We Doing and Where Are We Going? BMJ 2021 , 372 , n180. [ Google Scholar ] [ CrossRef ]

- Abu-Elmagd, K.; Fung, J.; Bueno, J.; Martin, D.; Madariaga, J.R.; Mazariegos, G.; Bond, G.; Molmenti, E.; Corry, R.J.; Starzl, T.E. Logistics and Technique for Procurement of Intestinal, Pancreatic, and Hepatic Grafts from the Same Donor. Ann. Surg. 2000 , 232 , 680–687. [ Google Scholar ] [ CrossRef ]

- Fu, H.; Ke, G.Y.; Lian, Z.; Zhang, L. 3PL Firm’s Equity Financing for Technology Innovation in a Platform Supply Chain. Transp. Res. Part E Logist. Transp. Rev. 2021 , 147 , 102239. [ Google Scholar ] [ CrossRef ]

- Ferrari, P. The Reasons for the Success of Freight Rail Transport through the Swiss Alps|Le Ragioni del Successo del Trasporto Ferroviario delle Merci Attraverso le Alpi Svizzere. Ing. Ferrov. 2019 , 74 , 9–26. [ Google Scholar ]

- Hess, A.-K.; Schubert, I. Functional Perceptions, Barriers, and Demographics Concerning e-Cargo Bike Sharing in Switzerland. Transp. Res. Part D Transp. Environ. 2019 , 71 , 153–168. [ Google Scholar ] [ CrossRef ]

- Eurostat Sustainable Development in the European Union: Monitoring Report on Progress towards the SDGS in an EU Context ; Publications office of the European Union: Maastricht, The Netherlands, 2017; ISBN 92-79-72288-3.

- European Union. European Union Horizon 2020 in Brief. In The EU Framework Programme for Research and Innovation ; European Union: Maastricht, The Netherlands, 2014. [ Google Scholar ]

- Stoll, J.; Harrison, H.; De Sousa, E.; Callaway, D.; Collier, M.; Harrell, K.; Jones, B.; Kastlunger, J.; Kramer, E.; Kurian, S.; et al. Alternative Seafood Networks During COVID-19: Implications for Resilience and Sustainability. Front. Sustain. Food Syst. 2021 , 5 , 614368. [ Google Scholar ] [ CrossRef ]

- Tendall, D.; Joerin, J.; Kopainsky, B.; Edwards, P.; Shreck, A.; Le, Q.B.; Krütli, P.; Grant, M.; Six, J. Food System Resilience: Defining the Concept. Glob. Food Secur. 2015 , 6 , 17–23. [ Google Scholar ] [ CrossRef ]

- Li, D.; Wang, X.; Chan, H.K.; Manzini, R. Sustainable Food Supply Chain Management. Int. J. Prod. Econ. 2014 , 152 , 1–8. [ Google Scholar ] [ CrossRef ]

- Neven, D. Developing Sustainable Food Value Chains ; FAO: Rome, Italy, 2014; ISBN 92-5-108481-5. [ Google Scholar ]

- Mishra, D.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R. Supply Chain Performance Measures and Metrics: A Bibliometric Study. Benchmarking Int. J. 2018 , 25 , 932–967. [ Google Scholar ] [ CrossRef ]

- Guersola, M.; Pinheiro de Lima, E.; Steiner, M. Supply Chain Performance Measurement: A Systematic Literature Review. Int. J. Logist. Syst. Manag. 2018 , 31 , 109. [ Google Scholar ] [ CrossRef ]

- Perdana, T.; Onggo, B.; Sadeli, A.; Chaerani, D.; Achmad, A.; Rahayu, F.; Gong, Y. Food Supply Chain Management in Disaster Events: A Systematic Literature Review. Int. J. Disaster Risk Reduct. 2022 , 79 , 103183. [ Google Scholar ] [ CrossRef ]

- Rahbari, M.; Arshadi Khamseh, A.; Mohammadi, M. Robust Optimization and Strategic Analysis for Agri-Food Supply Chain under Pandemic Crisis: Case Study from an Emerging Economy. Expert Syst. Appl. 2023 , 225 , 120081. [ Google Scholar ] [ CrossRef ]

- Singh, R.; Sinha, V.; Joshi, P.; Kumar, M. Modelling Agriculture, Forestry and Other Land Use (AFOLU) in Response to Climate Change Scenarios for the SAARC Nations. Environ. Monit. Assess. 2020 , 192 , 1–18. [ Google Scholar ] [ CrossRef ]

- Divergences, N.G. World Economic Outlook. 2023. Available online: https://www.imf.org/en/Publications/WEO/Issues/2023/10/10/world-economic-outlook-october-2023 (accessed on 29 April 2024).

- Ponomarov, S.; Holcomb, M. Understanding the Concept of Supply Chain Resilience. Int. J. Logist. Manag. 2009 , 20 , 124–143. [ Google Scholar ] [ CrossRef ]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of Internal Integration, Supply Chain Partnership, Supply Chain Agility, and Supply Chain Resilience on Sustainable Advantage. Sustainability 2021 , 13 , 5460. [ Google Scholar ] [ CrossRef ]

- Zidi, S.; Hamani, N.; Kermad, L. New Metrics for Measuring Supply Chain Reconfigurability. J. Intell. Manuf. 2022 , 33 , 2371–2392. [ Google Scholar ] [ CrossRef ]

- Zhang, S.; Wang, H.; Li, G.; Wang, J. Modeling of the Resilient Supply Chain System from a Perspective of Production Design Changes. Front. Eng. Manag. 2023 , 10 , 96–106. [ Google Scholar ] [ CrossRef ]

- Brundtland, G.H. World Commission on Environment and Development. Environ. Policy Law 1985 , 14 , 26–30. [ Google Scholar ]

- Yao, Q.; Liu, J.; Sheng, S.; Fang, H. Does Eco-Innovation Lift Firm Value? The Contingent Role of Institutions in Emerging Markets. J. Bus. Ind. Mark. 2019 . ahead of print . [ Google Scholar ] [ CrossRef ]

- Althaf, S.; Babbitt, C.W. Disruption Risks to Material Supply Chains in the Electronics Sector. Resour. Conserv. Recycl. 2021 , 167 , 105248. [ Google Scholar ] [ CrossRef ]

- Zeng, X.; Mathews, J.A.; Li, J. Urban Mining of E-Waste Is Becoming More Cost-Effective than Virgin Mining. Environ. Sci. Technol. 2018 , 52 , 4835–4841. [ Google Scholar ] [ CrossRef ]

- Nosalska, K.; Piątek, Z.; Mazurek, G.; Rządca, R. Industry 4.0: Coherent Definition Framework with Technological and Organizational Interdependencies. J. Manuf. Technol. Manag. [ CrossRef ]

- Munongo, S.; Pooe, D. Small and Medium Enterprises’ Adoption of 4IR Technologies for Supply Chain Resilience during the COVID-19 Pandemic. J. Transp. Supply Chain. Manag. 2022 , 14 , 747. [ Google Scholar ] [ CrossRef ]

- Kumar, A.; Singh, R.K. Supply Chain Management Practices, Retail Outlets Attributes and Organisational Performance: A Case of Organised Food Retailers in India. J. Glob. Oper. Strateg. Sourc. 2023 , 16 , 568–589. [ Google Scholar ] [ CrossRef ]

- Nisar, Q.A.; Haider, S.; Ameer, I.; Hussain, M.S.; Gill, S.S.; Usama, A. Sustainable Supply Chain Management Performance in Post COVID-19 Era in an Emerging Economy: A Big Data Perspective. Int. J. Emerg. Mark. 2022; ahead of print . [ Google Scholar ] [ CrossRef ]

- Miljenović, D.; Beriša, B. Pandemics Trends in E-Commerce: Drop Shipping Entrepreneurship during COVID-19 Pandemic. Pomorstvo 2022 , 36 , 31–43. [ Google Scholar ] [ CrossRef ]

- Laborde, D.; Martin, W.; Swinnen, J.; Vos, R. COVID-19 Risks to Global Food Security. Science 2020 , 369 , 500–502. [ Google Scholar ] [ CrossRef ]

- Yearbook, F.S. World Food and Agriculture ; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; Volume 15. [ Google Scholar ]

- Kim, B.; Kim, G.; Kang, M. Study on Comparing the Performance of Fully Automated Container Terminals during the COVID-19 Pandemic. Sustainability 2022 , 14 , 9415. [ Google Scholar ] [ CrossRef ]

- ISO 9001:2015 ; Quality Management Systems-Requirements. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://committee.iso.org/standard/62085.html (accessed on 13 June 2024).

Click here to enlarge figure

| Source | No. of Papers | Scimago Ranking |

|---|---|---|

| Sustainability (Switzerland) | 10 | Q1–Q2 |

| International Journal of Logistics Management | 6 | Q1 |

| Journal of Global Operations and Strategic Sourcing | 5 | Q2 |

| Agricultural Systems | 5 | Q1 |

| Benchmarking | 4 | Q1 |

| International Journal of Production Research | 3 | Q1 |

| Research Method | No. of Papers |

|---|---|

| ANOVA | 2 |

| Contingency analysis and frequency analysis | 1 |

| Cronbach’s alpha | 1 |

| Descriptive statistics | 8 |

| Econometric | 1 |

| Hypothesis test | 5 |

| Keyword analysis | 1 |

| Logistic regression—R software | 1 |

| Partial Least Square (PLS) | 1 |

| PLS-SEM | 11 |

| Random forest regression | 1 |

| Regression | 3 |

| SEM | 9 |

| Descriptive statistics, bias and common method variance test, multiple regression analysis and mediation test | 1 |

| Analysis with SPSS and Nvivo | 1 |

| Best Worst Method | 1 |

| Decision-Making Trial and Evaluation Laboratory (DEMATEL) | 1 |

| DEMATEL—Maximum mean de-entropy (MMDE) | 1 |

| Fuzzy | 10 |

| ISM | 1 |

| ISM-Bayesian network (BN) | 1 |

| ISM-Cross-Impact Matrix Multiplication Applied to Classification (MICMAC) | 1 |

| Multi-Attribute Decision Making (MADM) | 1 |

| Multi-Attribute Utility Theory (MAUT) | 1 |

| Multi-Criteria Decision Methods (MCDM) | 6 |

| SWOT analysis | 2 |

| Total Interpretive Structural Modelling (TISM) + MICMAC analysis | 1 |

| Case study | 7 |

| Framework and case study | 1 |

| Product design changes (PDC)—domain modelling | 1 |

| Qualitative | 5 |

| ABC analysis | 2 |

| Poisson pseudo-maximum likelihood (PPML) | 1 |

| Method of stochastic factor economic–mathematical analysis | 1 |

| Discrete Event Simulation (DES) | 1 |

| System dynamics approach | 1 |

| Multi-period simulation | 1 |

| Industrial Sector | No. of Papers |

|---|---|

| Logistics | 13 |

| Manufacturing | 4 |

| Food | 4 |

| Automotive | 3 |

| Agri-food | 3 |

| Industrial Sector | No. of Papers |

|---|---|

| Logistics | 10 |

| Food | 7 |

| Agri-food | 6 |

| Manufacturing | 6 |

| Healthcare | 2 |

| Electronic | 2 |

| Industrial Sector | No. of Papers |

|---|---|

| Logistics | 9 |

| Food | 3 |

| Agri-food | 3 |

| Manufacturing | 2 |

| The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Share and Cite

Monferdini, L.; Bottani, E. Examining the Response to COVID-19 in Logistics and Supply Chain Processes: Insights from a State-of-the-Art Literature Review and Case Study Analysis. Appl. Sci. 2024 , 14 , 5317. https://doi.org/10.3390/app14125317

Monferdini L, Bottani E. Examining the Response to COVID-19 in Logistics and Supply Chain Processes: Insights from a State-of-the-Art Literature Review and Case Study Analysis. Applied Sciences . 2024; 14(12):5317. https://doi.org/10.3390/app14125317

Monferdini, Laura, and Eleonora Bottani. 2024. "Examining the Response to COVID-19 in Logistics and Supply Chain Processes: Insights from a State-of-the-Art Literature Review and Case Study Analysis" Applied Sciences 14, no. 12: 5317. https://doi.org/10.3390/app14125317

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

Measuring Circularity in Life Cycle Management: A Literature Review

- REVIEW PAPERS

- Open access

- Published: 25 June 2024

Cite this article

You have full access to this open access article

- Vincenzo Basile ORCID: orcid.org/0000-0001-8776-0915 1 ,

- Nunzia Petacca 1 &

- Roberto Vona ORCID: orcid.org/0000-0002-4633-030X 1

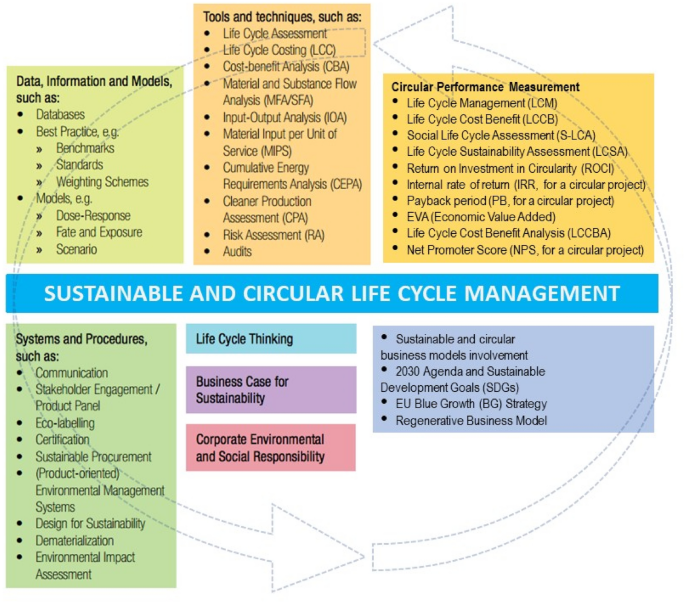

Circularity has emerged as a pivotal concept in the realm of sustainable resource management and business operations. Resource exhaustion and environmental degradation propelled by globalization and the culture of consumerism have intensified the focus on the concept of the circular economy around the world. Nevertheless, the evaluation and quantification of circularity achievements remain uncommon in corporate practices. This article employs a systematic literature review to delve into circularity measurements in the managerial life cycle. Key approaches emerging from the academic literature are examined, including life cycle costing, life cycle assessment, life cycle cost–benefit, life cycle benefit analysis, and life cycle sustainability assessment. The review seeks to offer a comprehensive overview of the methodologies employed to assess circularity in corporate processes, highlighting current challenges and opportunities for effective implementation. We adopt a conceptual model of sustainable and circular life cycle management based on specific performance indicators that allow the environmental, social, and economic impact of processes to be assessed throughout the life cycle of products or services. The implementation of Sustainable and Circular Life Cycle Management from a managerial perspective could support firms to eradicate and quantify waste, preserve the inherent value of products and materials, encourage the adoption of renewable energies, and eliminate harmful chemicals.

Avoid common mistakes on your manuscript.

Introduction

As the world grapples with the urgent need to measure sustainability, flexible systems are emerging as promising approaches to resource optimisation and circularity (Sushil & Dinesh, 2022 ). In particular, the flexibility issue has become central to the flexible management system (D’Adamo et al., 2024 ), mainly in the last 2 years in the manufacturing industry (Tootell et al., 2023 ) and in sustainable business development (Litvinova et al., 2023 ). By embracing adaptability and responsiveness, these systems could effectively manage the flow of materials, energy, and information throughout their lifespan, minimizing waste and maximizing resource utilization (Singh et al., 2023 ). Harnessing the power of flexibility in Life Cycle Management (LCM) offers a transformative path towards a more sustainable future (Sushil, 2015 ). LCM encompasses the entire life cycle of a product, from its design and production to its use, maintenance, end-of-life treatment, and recycling. By integrating flexibility into each stage of LCM, businesses and organizations can unlock a wealth of opportunities to reduce their environmental footprint and promote sustainable practices. Considering this transformative scenario, the primary goal of the European Green Deal is to achieve climate neutrality by 2050. This plan focuses on identifying leading companies in the field of green technologies and products while simultaneously stimulating the development of new markets for products that promote recycling and have a climate-neutral impact. The central objective is to develop an economy based on circularity, with a particular focus on biodiversity conservation and the creation of an equitable and socially just transition process. Europe has positioned itself as a leader in both the industrial and political spheres to drive global change. Moreover, according to Saidani et al. ( 2022 ), elevating the degree of circularity within the economy enhances the chances of attaining the Sustainable Development Goals (SDGs) outlined by the United Nations (UN, 2015), especially in terms of responsible production and consumption (SDG 12). The need to promote such change arises from the evidence in the Global Resources Outlook 2019 (Oberle et al., 2019 ) that global annual resource extraction tripled from 1970 to 2017 and continues to rise. Resource extraction and transformation account for more than 90% of both biodiversity loss and water imbalances (UNEP IRP, 2019), and despite the circular economy (CE) action plan initiated by the European Commission in 2015, a mere 12% of the materials utilised by industries within the European Union are sourced from recycling. Full implementation of circular processes has only been applied to nine per cent of the global economy, leaving ample room for improvement. Over the last decade, the notion of a CE has garnered increased interest from governments, businesses, researchers, and politicians and has been perceived as a fundamental step towards achieving sustainable development (Corona et al., 2019 ). Globally, the circular economy is recognized for its ability to promote resource efficiency (Ellen MacArthur Foundation, 2015 ). Through practices such as reuse, recycling, and regeneration, it maximizes the value of products and materials, reducing waste and contributing to mitigating climate change (European Environment Agency, 2020 ). In the European context, the circular economy is gaining prominence as a key strategy for achieving sustainability goals. The European Union has developed ambitious plans, such as the Circular Economy Action Plan, to transition towards a more circular economy (European Commission, 2020 ). This includes measures to promote eco-design, resource efficiency, and waste reduction across member states. Italy, with its rich cultural and industrial heritage, is well-positioned to embrace the principles of the circular economy. Key sectors such as fashion, automotive, and furniture can benefit from adopting circular practices, improving resource efficiency, and reducing production costs (Pozzo, 2021 ). The Italian government has also recognized the importance of the circular economy through policies such as the National Strategy for the Circular Economy, providing a strategic framework for transitioning towards a more sustainable and resource-efficient economy (Italian Ministry of Economic Development, 2017 ). For Italian businesses, embracing the circular economy offers tangible benefits. Besides the economic savings resulting from resource efficiency and waste reduction, there are also opportunities for market differentiation and brand reputation enhancement (Carlisle & Faulkner, 2005 ). Furthermore, innovation in product design and sustainable business models (Basile et al., 2021a , 2021b ) can create new business opportunities (Boston Consulting Group, 2019 ). The circular economy represents a significant opportunity to promote sustainability and economic prosperity, both globally, within Europe, and in the Italian context. Businesses that adopt circular economy principles can benefit from cost savings, market differentiation opportunities, and regulatory compliance, positioning themselves for long-term success in an increasingly circular economy (PricewaterhouseCoopers, 2021 ). While there are numerous accredited definitions of the CE, and despite the introduction of the concept many decades ago, a specific definition and conceptual framework remain subjects of ongoing debate and uncertainty, as highlighted by Reike et al. ( 2018 ). In a recent literature review (Kirchherr et al., 2017 ), 114 interpretations of the CE were identified from various sources, including peer-reviewed articles, policy papers, and consulting reports. As the World Economic Forum argues, “ The circular economy is a model of economic development that aims to rethink how we create economic value. Instead of a “take, make, dispose” philosophy, it promotes a “take, make, reuse, repair, recycle” perspective ” (World Economic Forum, 2014 ). In addition, the European Commission explains that “ The circular economy focuses on waste reduction, material reuse, and recycling, as well as the regeneration of natural systems. This results in economic and environmental benefits, such as increased competitiveness and supply chain security, greater economic resilience to shocks, and a reduction in greenhouse gas emissions and pollution ” (European Commission, 2015 ).

The most widely recognized definition of the CE was formulated by the Ellen MacArthur Foundation ( 2013 ): “ A circular economy is a regenerative system in which materials and resources retain their value and utility for as long as possible, and waste and resource usage is minimized. It involves the extraction of materials, production, use, and regeneration, aiming to keep products, components, and materials at their highest value and utility at every stage of their lifecycle ”. The measurement of circularity is important in managerial disciplines because it is connected to several fundamental dimensions of the success of organizations and businesses. Circularity involves the adoption of practices and business models focused on diminishing environmental impact, promoting resource efficiency, preventing waste, and emphasizing the value of reuse and recycling. In other words, circular management aims to create a more sustainable and long-term economy. The measuring of circularity helps companies identify and monitor their environmental impact. With a better understanding of how resources are used and managed, organizations can reduce pollution, waste production, and natural resource depletion. The adoption of circular practices can lead to a more efficient use of resources, thereby reducing operational costs. For example, reusing and recycling can decrease the need to purchase new raw materials, thereby contributing to cost savings. Companies distinguished by their circular management can gain a competitive advantage, as consumers and business partners are increasingly attentive to sustainability and prefer to do business with environmentally responsible organizations. Companies adopting circular business models tend to be more resilient to fluctuations in raw material prices and environmental shocks, as they have a greater capacity to adapt to resource-related challenges. This work aims to examine, through a systematic literature review, the various approaches proposed so far to investigate the measurement of circularity in the managerial life cycle. Furthermore, it aims to provide guidelines for defining the dimensions and variables to consider in the development of a comprehensive methodology to measure and evaluate the degree of circularity of a system throughout its life cycle. The article is structured as follows: Sect. " Method and research model " describes the research methodology and criteria employed to analyse documents related to performance assessment in the context of the CE. Section " Measuring circularity in life cycle management " presents the results of the review, highlighting the approaches that have been presented thus far as well as the differences and similarities in these specific fields. Section " Results " first discusses the limitations of the various approaches and highlights the theoretical implications for performance evaluation in the CE. Finally, Sect. " Theoretical implications " concludes the contribution, presenting the main observations and outlining future research suggestions.

Circularity and Life Cycle Management for Flexible Firms

Measuring circularity in LCM is crucial to fostering flexibility and enhancing an organisation’s ability to adapt to changing market demands and environmental conditions (Saidani et al., 2017 ). By tracking key circularity metrics (CMs), such as material reuse rates, the proportion of waste diversion, and energy efficiency, organizations can gain valuable insights into their resource consumption patterns and identify areas for improvement (Corona et al., 2019 ). This information empowers decision-makers to make informed choices about product design, manufacturing processes, and waste management strategies, enabling them to transition towards more circular business models. Specifically, circularity measurement helps organisations:

Reduce Material Dependency (Gebhardt et al., 2022 ). By quantifying the materials that are used and reused, organizations can identify specific areas where they can decrease their dependence on virgin resources, thus minimizing their environmental footprint. This flexibility allows them to adapt to fluctuations in resource availability and cost, ensuring a secure and sustainable supply chain.

Improve Waste Management Efficiency (Kurdve et al., 2015 ). Tracking waste generation and diversion rates provides organizations with actionable data to optimize their waste management practices, enabling them to pinpoint the most effective waste reduction and recycling strategies, thereby diminishing the volume of waste directed to landfills and redirecting resources back into the production cycle. This flexibility enhances their ability to comply with environmental regulations and demonstrate their commitment to sustainable practices.