NEWS & INSIGHTS > Thought Leadership > A Case Study in Design for Manufacturing and Assembly

A Case Study in Design for Manufacturing and Assembly

Aug 06, 2021

U.S. Engineering

by Jeff Kiblen , Associate Vice President, U.S. Engineering Innovations

Design for Manufacturing and Assembly (DfMA) is one method U.S. Engineering Innovations (USEI) is implementing in our quest to reimagine ways to execute construction projects. I introduced DfMA and talked about how we’re using it in my first article in this series .

This article examines a recent project that used DfMA to produce a duct module component. Our design partners at Henderson Engineers worked with a client who was interested in using modular design and construction in their HVAC airside systems. Because of its potential for a repeatable floor plan, which could be mirrored for left and right applications, this project was a viable candidate for DfMA. We could design, manufacture and assemble the same duct modules for both configurations.

Design for Manufacturing and Assembly in Practice

Our process with Henderson began as an exercise to find a duct size that made the most effective use of USEI’s standard metal coil widths. The right size would drive out waste and maximize our machine capacities. Simultaneously, Henderson ran all the critical engineering calculations to establish the most flexible size module for their designs.

Once the basis of the design was established, our virtual construction teams consolidated the design content and coordinated with structure and ceiling to make everything fit within the envelope. They then converted that BIM content into buildable components for our shop floors.

Investment in Manufacturing Infrastructure

A key factor that enables us to work closely and seamlessly with our design partners on DfMA projects like this one is our commitment to improving our manufacturing infrastructure. For years we’ve invested in the machinery on the floors of our manufacturing facilities. We’ve invested in the software that communicates with that machinery. And we’ve invested in the teams that code the software and operate the machines.

Thanks to those investments, DfMA projects like this one are true joint efforts: we’re able to drive designs to work best within our machinery’s capabilities, all the while being completely attentive to meeting client needs.

As Henderson’s Sean Turner notes in his article about this case study, the owner’s goals in this case were to reduce costs and improve schedule. USEI helped achieve those goals by driving a common design and size for all of the owner’s store configurations and by performing 70+% of the mechanical work in our facility. As a result, we removed almost three weeks from the original build schedule.

A Sustainable Future in Construction

DfMA dramatically reduces the margin of error. From design to manufacturing to installation, the process is safer and more reliable than the traditional approach. But the process also improves sustainability, a topic USEI and Henderson take seriously. We work in a historically wasteful industry and are actively seeking out ways to minimize project excess. DfMA, in its effort to maximize efficiency, is a design-build method that reduces elements of the manufacturing process that end up in landfills.

Whether designing shipping frames that become the supplemental hanging steel on site after delivery, or repurposing modules like the ones we created on this project for completely different builds, we see DfMA as a method of sustainability. And we’ll continue to explore this approach on future builds.

Jeff Kiblen is Associate Vice President of U.S. Engineering Innovations and K-Malt, a wholly owned subsidiary. Starting as a pipefitter apprentice in Kansas City, he spent a decade in the field working his way up to superintendent. From there, because of his passion for technology and problem solving, he pivoted to virtual construction and building information modeling. Today he and his family reside in Colorado.

Related Posts

See where our innovative thinkers and expert collaborators can take you..

Want to create or adapt books like this? Learn more about how Pressbooks supports open publishing practices.

Chapter 1: Introduction to DFMA

The history of dfma.

Review the DFMA timeline below to become familiar with the most significant milestones leading to the development and use of DFMA in engineering practices. Select the arrow on the right side of the interactive timeline to progress through the decades. You can also select the icon in the upper right corner to expand your view.

So, what is DFMA?

Design for Manufacture and Assembly (DFMA) is an engineering methodology which focuses on reducing time-to-market and total production costs by prioritizing the following during the early design phases of the product life cycle.

- Ease of manufacture for the product’s parts.

- Simplified assembly of those parts into the final product

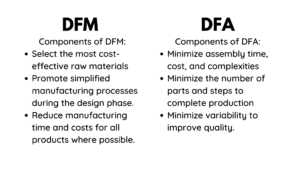

DFMA is comprised of two components: Design for Manufacturing (DFM) and Design for Assembly (DFA).

The goal is to design a product which makes the customer happy and is the lowest overall cost, but there are other factors as well:

- Best material for the process and product

- Minimum number of components

- Easy to acquire to the components

- Easy to assemble

- Easy to maintain the device

- Easy to recycle at the end of the product’s life

The product starts and ends with the customer. It could be called the voice of the customer, stakeholder input/analysis, customer request, scope of work, or critical quality requirements. Learn more about how to manufacture success by reviewing the following plan by David M. Vranson: A Plan for Manufacturing Success (2011)

Boothroyd Dewhurst, Inc. (2018). What is DFMA? [Video]. YouTube. https://www.youtube.com/watch?v=H6XtXCvhaec

Boothroyd Dewhurst, Inc. (2010). Case study: Desgin in cost reduction. Quality Magazine. Retrieved on May 8, 2023 from https://www.qualitymag.com/articles/84738-case-study-design-in-cost-reduction

DFMA (2023). How do you reduce cost while still achieving function, reliability, and time to market objectives? Retrieved on May 8, 2023 from https://www.dfma.com/

Dong, D., Zou, Y., Pan, H., Zhou, G., Feng, Y., & Tang, Y. (2023). DFMA-oriented modular and parametric design and secondary splitting of vertical PC components. Scientific Reports, 13. https://doi.org/10.1038/s41598-023-30192-z

Favi, C., Mandolini, M., Campi, F., Cicconi, P., Raffaeli, R., & Germani, M. (2021). Design for manufacturing and assembly: A method for rules classification. Advanances on Mechanics, Design Engineering, and Manufacturing III. https://doi.org/10.1007/978-3-030-70566-4_56

Formentini, G., Rodriguez, N., & Favi, C. (2022). Design for manufacturing and assembly methods in the product development process of mechanical products: A systematic literature review. The International Journal of Advanced Manufacturing Technology, 120. https://doi.org./10.1007/s00170-022-08837-6

Goldense, B. (2022). A history of design for manufacturing and assembly. MachineDesign. Retrieved on June 23, 2023 from https://www.machinedesign.com/automation-iiot/article/21213546/a-history-of-design-for-manufacturing-and-assembly

Liu, H., Zhang, Y., Lei, Z., Li, H., Han, S. (2021). Design for manufacturing and assembly: A BIM-Enabled generated framework for building panelization design. Smart Manufacturing for Industrialized Construction. https://doi.org/10.1155/2021/555455

Maverick, J. (2023). Is it more important for a company to lower costs or increase revenue? Investopedia. Retrieved on May 8, 2023 from https://www.investopedia.com/ask/answers/122214/company-it-more-important-lower-costs-or-increase-revenue.asp

de Oliveira, S., dos Santos, M., Kieling, A. (2021). The integration of DFMA and reverse engineering applied to a landing gear redesign. Journal of Engineering and Technology for Industrial Applications, 7 (31). https://doi.org/10.5935/jetia.v7i31.775

Roxas, C., Bautistia, C., Cruz, O., Dela Crus, R., De Pedro, J., Bungca, J., Lejano, B., & Ongpeng, J. (2023). Design for manufacturing and assembly and design for deconstruction in the construction industry: Challenges, trends, and developments. Buildings, 13 (5). https://doi.org/10.3390/buildings13051164

Siemens (2023). Design for manufacturing and assembly. Retrieved on May 8, 2023 from https://www.plm.automation.siemens.com/global/en/our-story/glossary/design-for-manufacturing-and-assembly-dfma/53982

Design for Manufacture and Assembly by Roberta Gagnon and Andrea Bearman is licensed under a Creative Commons Attribution 4.0 International License , except where otherwise noted.

Share This Book

Design for Manufacture and Assembly (DfMA)

Design for Manufacture & Assembly (DfMA) is an engineering design methodology designers and manufacturers should use to minimise cost and increase the quality of product designs.

Contents covered in this article

What is Design for Manufacture and Assembly?

DfMA is a design methodology that emphasises manufacturing simplicity and assembly efficiency. As a result, a product’s design can be improved to enable faster, safer, more cost-effective, and more efficient manufacturing and assembly.

Design for Manufacture and Assembly consists of two primary methodologies. One for manufacturing and another for assembly. They are Design for Manufacture (DFM) and Design for Assembly (DFA). DFM and DFA aim to optimise design while lowering labour, materials, and overhead costs.

What is Design for Manufacture?

DFM entails designing a product’s parts to be as simple to manufacture as possible. Therefore, choosing the most economical materials and production methods is essential, reducing the manufacturing process’s complexity.

Principles of DfM

- The parts should be made to fit within the tolerance limits of the manufacturing process .

- The part should be defined as a manufacturing process at an early stage

- Part features should be within the capabilities of the chosen manufacturing process

- A designer should explore and improve all manufacturing functions, including fabrication, assembly, testing, procurement, shipping, service, and repair of parts and assembly

What is Design for Assembly?

Dfa entails designing a product to be simple to assemble. It focuses on minimising the number of assembly operations and lowering the cost of product assembly.

Typical products go through the following stages and checks.

- Manufactured or procured

- Life cycle managed

Since each part you design and introduce has to go through the above stages, the cost of managing a single component adds up; hence reducing the part is the most significant function of the DFA.

Principles of Design for Assembly

Recommendation by Ulrich & Eppinger (1995)

- Reduce part count and part types

- Strive to eliminate adjustments

- Design parts to be self-aligning and self-locating

- Ensure adequate access and unrestricted vision

- Ensure the ease of handling of parts from bulk

- Minimise the need for reorientations during assembly

- Design parts that cannot be installed incorrectly

- Maximise part symmetry if possible or make parts asymmetric

- Eliminate processing steps

- Choose the appropriate economic scale for the process

- Standardise components and processes

- Adhere to “Black Box” component procurement (describe what the component has to do, not how to achieve it)

- Minimise system complexity

Advantages and Disadvantages of Design for Manufacture and Assembly

Advantages of dfma.

- Reduced waste

- Lower manufacturing

- Fewer design changes during the later stages of the design process

- DfMA significantly reduced the assembly cost by using fewer parts, requiring less labour, and using fewer unique parts.

Disadvantages of DfMA

- Prices rise due to high startup costs for factories and a lack of demand for mass-produced goods.

- Design for manufacture and assembly methodology is not always the cheapest option as it depends on quantity.

Design for Assembly classification system

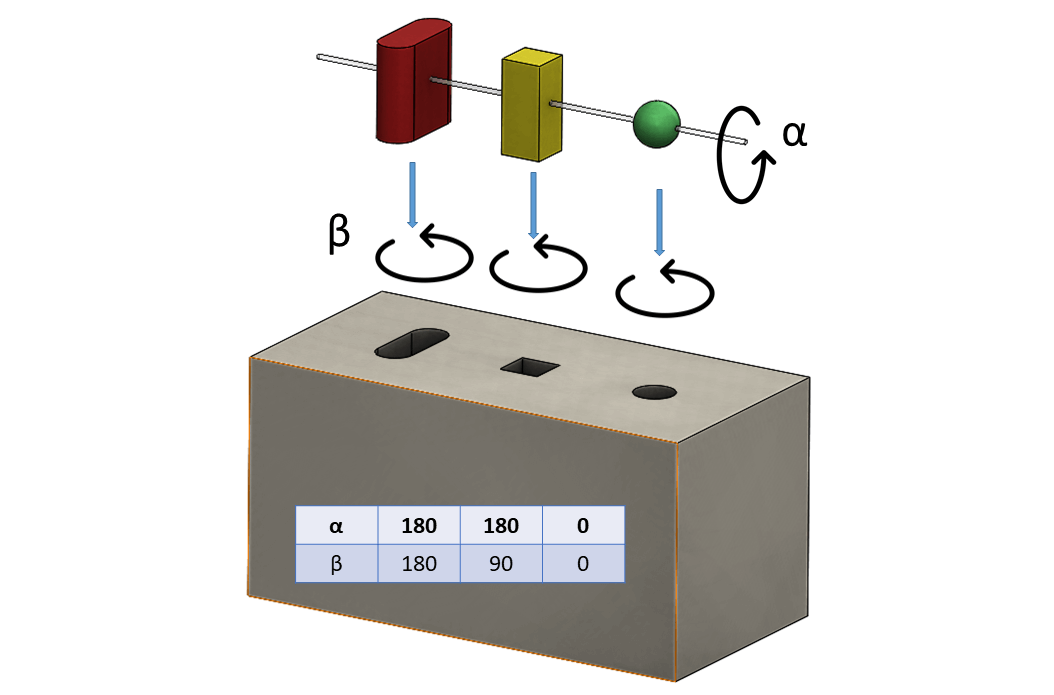

Design for Assembly (DFA) manual handling classification systematically quantifies how features affect the manual handling of parts during assembly.

What is the Design for assembly classification?

So what is Design for Assembly? It can be defined as a method of designing items with the simplicity of assembly in mind.

Design for assembly should be considered at all 4 stages of the product design process , especially during the embodiment stage of the design.

It’s difficult to analyze and compare design solutions systematically without a methodology to quantify an engineering product design. To overcome this issue Boothroyd and Dewhurst came up with a system to quantify a design using simple manual assembly techniques.

Boothroyd and Dewhurst’s classification system, systematically quantify how features affect the manual handling of the part during the assembly. They divided the classification and assembly method into two main categories. Manual handling and manual insertion and graded them according to how difficult it is to handle and insert by allocating time for each activity.

Full classification and definition can be found in their book (“Product design for manufacture and assembly” (Boothroyd Dewhurst Inc 1999)

Benefits of a DFA classification system

- It quantifies the process

- Quick results

- Simple and easy to use

- It eliminates subjective judgment during the design review

- Ideas, reasoning, and decision during this review can be documented

DFA Manual handling times

One hand without tools

| One hand | Parts are easy to grasp & manipulate | Parts present handling difficulties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Parts can be grasped and manipulated by one hand without the aid of grasping tools | Thickness > 2 mm | Thickness ≤ 2 mm | Thickness > 2 mm | Thickness ≤ 2 mm | |||||||

| Size > 15 mm | 6 mm ≤ Size > 15 mm | Size | Size ≤ 6 mm | Size > 15 mm | 6 mm ≤ Size > 15 mm | Size | Size ≤ 6 mm | ||||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| (α + β) | 1.13 | 1.43 | 1.88 | 1.69 | 2.18 | 1.84 | 2.17 | 2.65 | 2.45 | 2.98 | |

| 360° ≤ (α + β) | 1.5 | 1.8 | 2.25 | 2.06 | 2.55 | 2.25 | 2.57 | 3.06 | 3 | 3.38 | |

| 540° ≤ (α + β) | 1.8 | 2.1 | 2.55 | 2.36 | 2.85 | 2.57 | 2.9 | 3.38 | 3.18 | 3.7 | |

| (α + β) = 720 ° | 3 | 1.95 | 2.25 | 2.7 | 2.51 | 3 | 2.73 | 3.06 | 3.55 | 3.34 | 4 |

Table 1. DFA Manual handling times – one hand without tools (Boothroyd, Dewhurst, & Knight, 2011)

One hand with tools

| One hand with grasping aids | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Parts can be grasped and manipulated by one handle but only with the use of grasping tools | Parts need tweezers for grasping and manipulation | Parts need standard tools other than tweezers | Parts need special tools for grasping and manipulation | |||||||||

| Parts can be manipulated without optical magnification | Parts require optical magnification for manipulation | |||||||||||

| Parts are easy to grasp and manipulate | Parts present handling difficulties (a) | Parts are easy to grasp and manipulate | Parts present handling difficulties (a) | |||||||||

| Thickness > 0.25 mm | Thickness ≤ 0.25 mm | Thickness > 0.25 mm | Thickness ≤ 0.25 mm | Thickness > 0.25 mm | Thickness ≤ 0.25 mm | Thickness > 0.25 mm | Thickness ≤ 0.25 mm | |||||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| α≤180° | 0≤β≤180° | 4 | 3.6 | 6.85 | 4.35 | 7.6 | 5.6 | 8.35 | 6.35 | 8.6 | 7 | 7 |

| β=360° | 5 | 4 | 7.25 | 4.75 | 8 | 6 | 8.75 | 6.75 | 9 | 8 | 8 | |

| α=360° | α≤β≤80° | 6 | 4.8 | 8.05 | 5.55 | 8.8 | 6.8 | 9.55 | 7.55 | 9.8 | 8 | 9 |

| β=360° | 7 | 5.1 | 8.35 | 5.85 | 9.1 | 7.1 | 9.55 | 7.85 | 10.1 | 9 | 10 | |

Table 2. DFA Manual handling times – one hand with tools (Boothroyd, Dewhurst, & Knight, 2011)

With both hands

| Two hands for manipulation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Parts severely nest or tangle or are flexible but can be grasped and lifted by one hand ( with the use of grasping tools if necessary)(b) | Parts present no additional handling difficulties | Parts present additional handling difficulties (Sticky, delicate, slippery etc) (a) | ||||||||

| α ≤ 180° | α = 360° | α ≤ 180° | α = 360° | |||||||

| Size > 15 mm | 6 mm ≤ Size > 15 mm | Size | Size ≤ 6 mm | Size > 15 mm | 6 mm ≤ Size > 15 mm | Size | Size ≤ 6 mm | |||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| 8 | 4.1 | 4.5 | 5.1 | 5.6 | 6.75 | 5 | 5.25 | 5.85 | 6.35 | 7 |

Table 3. DFA Manual handling times – one hand with tools (Boothroyd, Dewhurst, & Knight, 2011)

Both hands and assistance for large parts

| Two hands or assistance required for large size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Two hands or persons or mechanical assistance required for grasping and transporting parts | Parts can be handled by one person without mechanical assistance | Parts severely nest or tangle or are flexible (b) | Two persons or mechanical assistance required for parts manipulation | ||||||||

| Parts do not severely nest or tangle and are not flexible | |||||||||||

| Part weight | |||||||||||

| Parts are easy to grasp and manipulate | Parts present handling difficulties (a) | Parts are easy to grasp and manipulate | Parts present handling difficulties (a) | ||||||||

| α ≤ 180° | α = 360° | α ≤ 180° | α = 360° | α ≤ 180° | α = 360° | α ≤ 180° | α = 360° | ||||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| 9 | 2 | 3 | 2 | 3 | 3 | 4 | 4 | 5 | 7 | 9 | |

Table 4. DFA Manual handling times – one hand with tools (Boothroyd, Dewhurst, & Knight, 2011)

Boothroyd, G., Dewhurst, P., & Knight, W. A. (2011). Product design for Manufacture and Assembly. London: CRC Press.

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > Manufacturing Engineering

Applications of Design for Manufacturing and Assembly

Book metrics overview

9,151 Chapter Downloads

Impact of this book and its chapters

Total Chapter Downloads on intechopen.com

Total Chapter Views on intechopen.com

Book Citations

Total Chapter Citations

Academic Editor

Technical University of Cluj-Napoca , Romania

Published 03 January 2019

Doi 10.5772/intechopen.75475

ISBN 978-1-78984-936-3

Print ISBN 978-1-78984-935-6

eBook (PDF) ISBN 978-1-83881-825-8

Copyright year 2019

Number of pages 100

The book entitled Application of Design for Manufacturing and Assembly aims to present applicable research in the field of design, manufacturing, and assembly realized by researchers affiliated to well-known institutes. The book has a profound interdisciplinary character and is addressed to researchers, engineers, PhD students, graduate and undergraduate students, teachers, and other readers inter...

The book entitled Application of Design for Manufacturing and Assembly aims to present applicable research in the field of design, manufacturing, and assembly realized by researchers affiliated to well-known institutes. The book has a profound interdisciplinary character and is addressed to researchers, engineers, PhD students, graduate and undergraduate students, teachers, and other readers interested in assembly applications. I am confident that readers will find interesting information and challenging topics of high academic and scientific level within this book. The book presents case studies focused on new design for special parts using the principles of Design for Manufacturing and Assembly (DFMA), strategies that minimize the defects in design and manufacturing applications, special devices produced to replace human activity, multiple criteria analysis to evaluate engineering solutions, and the advantages of using the additive manufacturing technology to design the next generation of complex parts, in different engineering fields.

By submitting the form you agree to IntechOpen using your personal information in order to fulfil your library recommendation. In line with our privacy policy we won’t share your details with any third parties and will discard any personal information provided immediately after the recommended institution details are received. For further information on how we protect and process your personal information, please refer to our privacy policy .

Cite this book

There are two ways to cite this book:

Edited Volume and chapters are indexed in

Table of contents.

By Ancuţa Carmen Păcurar

By Ilesanmi Afolabi Daniyan and Khumbulani Mpofu

By Prashant Reddy Gangidi

By Martha Roselia Contreras Valenzuela, Alejandro David Guzmán, Diana Lagunas, Gerardo Vera Dimas, Alina Martínez Oropeza, Viridiana León-Hernández, Alber Eduardo Duque Alvarez and Roy López Sesenes

By Jonathan Becedas and Andrés Caparrós

By Ruta Miniotaite

IMPACT OF THIS BOOK AND ITS CHAPTERS

9,151 Total Chapter Downloads

2,467 Total Chapter Views

5 Crossref Citations

1 Web of Science Citations

19 Dimensions Citations

Order a print copy of this book

Available on

Delivered by

£100 (ex. VAT)*

Hardcover | Printed Full Colour

FREE SHIPPING WORLDWIDE

* Residents of European Union countries need to add a Book Value-Added Tax Rate based on their country of residence. Institutions and companies, registered as VAT taxable entities in their own EU member state, will not pay VAT by providing IntechOpen with their VAT registration number. This is made possible by the EU reverse charge method.

As an IntechOpen contributor, you can buy this book for an Exclusive Author price with discounts from 30% to 50% on retail price.

Log in to your Author Panel to purchase a book at the discounted price.

For any assistance during ordering process, contact us at [email protected]

Related books

Pulp and paper processing.

Edited by Md. Salim Newaz Kazi

Sustainable Drying Technologies

Edited by Jorge Del Real Olvera

Abrasive Technology

Edited by Anna Rudawska

Design and Manufacturing

Edited by Evren Yasa

Mass Production Processes

Edited by Anil Akdogan

Advances in 3D Printing

Edited by Ashutosh Sharma

Smart Manufacturing

Edited by Tan Yen Kheng

Infrared Spectroscopy

Edited by Theophile Theophanides

Frontiers in Guided Wave Optics and Optoelectronics

Edited by Bishnu Pal

Abiotic Stress in Plants

Edited by Arun Shanker

Call for authors

Submit your work to intechopen.

Design for manufacturing and assembly methods in the product development process of mechanical products: a systematic literature review

- Critical Review

- Open access

- Published: 14 March 2022

- Volume 120 , pages 4307–4334, ( 2022 )

Cite this article

You have full access to this open access article

- Giovanni Formentini ORCID: orcid.org/0000-0002-2321-6723 1 ,

- Núria Boix Rodríguez 1 &

- Claudio Favi 1

14k Accesses

22 Citations

Explore all metrics

This article has been updated

The design for manufacturing and assembly (DFMA) is a family of methods belonging to the design for X (DfX) category which goal is to optimize the manufacturing and assembly phase of products. DFMA methods have been developed at the beginning of the 1980s and widely used in both academia and industries since then. However, to the best of the authors’ knowledge, no systematic literature reviews or mapping has been proposed yet in the field of mechanical design. The goal of this paper is to provide a systematic review of DFMA methods applied to mechanical and electro-mechanical products with the aim to collect, analyse, and summarize the knowledge acquired until today and identify future research areas. The paper provides an overview of the DFMA topic in the last four decades (i.e., from 1980 to 2021) emphasizing operational perspectives such as the design phase in which methods are used, the type of products analysed, the adoption of quantitative or qualitative metrics, the tool adopted for the assessment, and the technologies involved. As a result, the paper addresses several aspects associated with the DFMA and different outcomes retrieved by the literature review have been highlighted. The first one concerns the fact that most of the DFMA methods have been used to analyse simple products made of few components (i.e., easy to manage with a short lead-time). Another important result is the lack of valuable DFMA methods applicable at early design phases (i.e., conceptual design) when information is not detailed and presents more qualitative than quantitative data. Both results lead to the evidence that the definition of a general DFMA method and metric adaptable for every type of product and/or design phase is a challenging goal that presents several issues. Finally, a bibliographic map was developed as a suitable tool to visualize results and identify future research trends on this topic. From the bibliometric analysis, it has been shown that the overall interest in DFMA methodologies decreased in the last decade.

Similar content being viewed by others

Directed Energy Deposition (DED) Process: State of the Art

A comprehensive literature review of the applications of AI techniques through the lifecycle of industrial equipment

Applications of artificial intelligence in engineering and manufacturing: a systematic review

Avoid common mistakes on your manuscript.

1 Introduction

The design for manufacturing and assembly (DFMA) is a family of methods belonging to the design for X (DfX) category which goal is to optimize the manufacturing and assembly phase of a product. DfX methodologies are used to improve specific aspects of the product under development. The X is generally substituted with the optimization goal, and these methodologies are used to support the product development process (PDP). DFA is a systematic procedure aiming at the reduction of assembly time through the following actions: (i) reduction of the overall number of components in a given assembly and (ii) elimination of critical assembly tasks [ 1 ]. DFM is an engineering practice that seeks the simplification of the manufacturing process for cost reduction of a given component through the following actions: (i) selection of raw material type, (ii) selection of raw material geometry, (iii) definition of dimensional and geometrical tolerances, (iv) definition of roughness, (v) characterization of specific shape constraints based on the manufacturing process, and (vi) selection of secondary processing such as finishing [ 2 ].

DFMA methods have been around for many years. The first DFMA method is dated back to the 1980s since it was noticed that a positive impact is obtainable on the overall costs if the manufacturing and assembly phases were challenged. Among the several methods developed on this aim, three approaches have been mainly used in both academia and industry: (i) Boothroyd and Dewhurst (B&D) [ 3 ], (ii) Hitachi [ 4 ], and (iii) Lucas method [ 5 ]. Despite the quite long history of this subject, only a few papers present a literature review about DFMA methods. For instance, Gao et al. [ 6 ], Ginting et al. [ 7 ], and Wasim et al. [ 8 ] proposed a review of DFMA methods in the building sector which shows different features compared with the mechanical products considered in this review. Regarding mechanical products, four reviews were focused on DFM methods [ 9 , 10 , 11 , 12 ], six on DFA methods [ 13 , 14 , 15 , 16 , 17 , 18 ], and four on DFMA methods [ 19 , 20 , 21 , 22 ]. By the analysis of these works, three main limitations have been identified. The first one concerns the fact that the majority of reviews are dated (conducted more than 15 years ago), and missing information about current DFMA methods and trends is noticed. The second one deals with the fact that some reviews have been published in conference proceedings and only limited outcomes are provided. Finally, the third limitation concerns the review methodology. The available reviews lack a systematic approach, not allowing the reproducibility and replicability of the review process. Although DFMA methods are widely used in both industrial and academic fields, there are no recent reviews on this topic for mechanical applications.

The goal of this paper is to provide a systematic review of DFMA methods applied to mechanical products. The systematic review was conducted to collect, analyse, and summarize the knowledge acquired until today, as well as to identify future research areas, following the results of relevant research works on this subject to answer specific research questions. Two clusters of research questions were identified by the authors: general questions (GQs), and focused questions (FQs). Each cluster presents a list of questions that are used to drive the review and to identify specific topics associated with the DFMA subject. The following topics were covered by this review: (i) the industrial fields and the type of products covered by DFMA methods, (ii) the mapping of the DFMA methods in relation to the product development phases, (iii) the identification of trends and challenges for DFMA methods, (iv) the metrics used to analyse the results of DFMA methods, (v) the design tools implemented in compliance with DFMA methods, and (vi) the use of Industry 4.0 enabling technologies in the development of DFMA methods.

In the following section, Sect. 2 , the method proposed to perform the systematic mapping is described in detail along with the chosen research questions. Then in Sect. 3 , the outcome of the performed review is reported showing data used to answer the research questions. Section 4 explaining the limitations of the proposed review is presented, followed by a discussion of the obtained results in Sect. 5 . Finally, the last section, Sect. 6 , summarizes the outcome of the review and highlights future research trends for DFMA methods.

2 Materials and methods

The method used to conduct the study is composed of five phases: (i) definition of the research questions, (i) definition of the search process, (iii) definition of criteria for article selection, (iv) execution of data extraction and classification, and (v) execution of the analysis The following part of this section describes each phase in detail, including how the literature review was performed.

2.1 Definition of research questions

For the development of this review, the following questions were obtained with a top-down approach. Research questions concerning DFMA methods were divided into two clusters GQs and FQs. The first cluster gives an overview of the research field, providing specific application fields and design phases in which DFMA methods have been applied the most, including future challenges of the studies that employ DFMA methods. The second cluster analyses technical aspects of DFMA methods, such as the method type, the tool used for computational reasons, and if Industry 4.0 enabling technologies were implemented. Table 1 reports the research questions defined for this review.

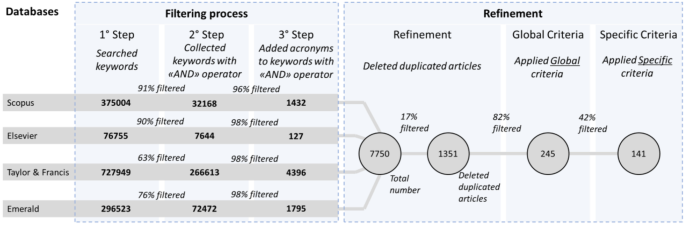

2.2 Definition of search process

Since the first research activities and applications about DFMA methods are dated back to the early 1980s, this review was conducted considering all papers published between 1980 and 2021. The research process was performed on four databases: (i) Scopus, (ii) Elsevier, (iii) Taylor & Francis, and (iv) Emerald, which were considered the most coherent publishers in the engineering sciences by the authors. The queries were filtered by authors, abstract, and keywords, when possible. Table 2 summarizes the filtering items used for each database.

The definition of keywords was performed iteratively due to the high number of papers resulting from the first database querying. To obtain a manageable number of articles, three filtering steps were performed as reported in Fig. 1 . Initially, general keywords such as “Design,” “Manufacturing,” “Assembly,” and “for” were collected with the operator “AND.” Moreover, to broaden the research and mitigate possible errors, synonyms were considered (i.e., “Manufacturability,” “Production,” “Manufacture,” “Assemblability,” and “Installation”). The second step was performed to narrow results, and the two keywords “Assembly” and “Manufacturing” were combined using the operator “AND” (e.g., “Assembly AND Production,” “Assembly AND Manufacture”). Finally, the last filtering step consisted in the introduction of new keywords to reduce the overall number of results trying to target only mechanical-related articles. The acronyms “DFA,” “DFM,” and “DFMA” were added to the previous keywords with the operator “AND.”

Filtering process and refinement steps

2.3 Definition of criteria for article sorting

After the initial search process, articles were skimmed with a three-step process: (i) identification and elimination of duplicated articles, (ii) use of global exclusion criteria to select articles related to the field of interest, and (iii) use of specific criteria (SC) to select only the most representative articles. Both criteria (GC and SC) used for the exclusion process are reported in Table 3 .

A quality assessment process was not performed, and all the retrieved papers were kept for the review process. At the end of the article selection, 141 articles were kept and analysed. The overall selection process is represented in Fig. 1 .

2.4 Execution of data extraction and classification

Data extraction and classification allowed for retrieving key information from the articles selected for the analysis using a structured framework. The data extraction framework (Table 4 ) is composed of items according to the type of research question they are answering.

2.5 Execution of analysis

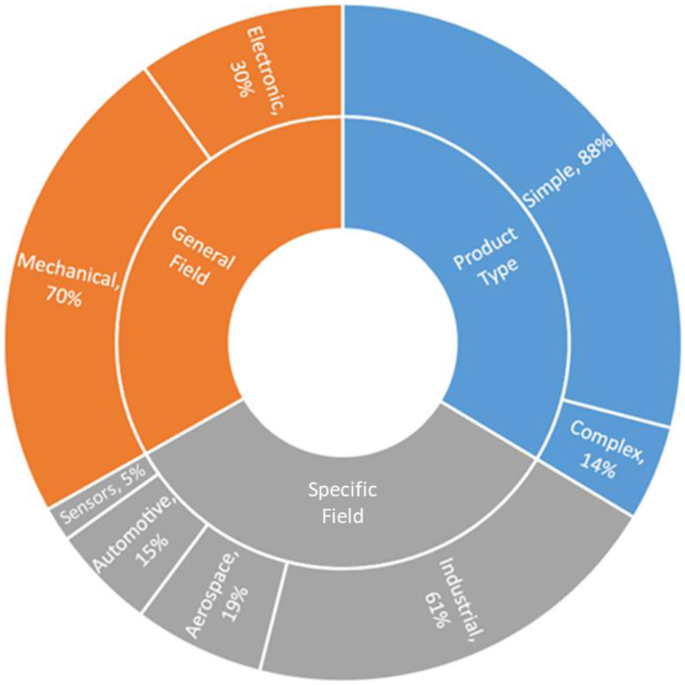

The execution of analysis was performed with the help of the framework provided in the previous step (Table 4 ). In relation to the general questions, the first topic concerns the identification of the specific field in which DFMA methods have been applied for years. Fields were divided into general (i.e., electronic, and mechanical) and specific (i.e., sensors, automotive aerospace, industrial). To further support this classification, the product complexity was identified. In this paper, a product is considered complex if it has a medium-long lead time and it is difficult to handle (i.e., due to weight, dimensions, or a high number of components), while a simple product has a short lead time and is made by few components (i.e., less than sixty). The second topic concerns the identification of the design phase in which DFMA is applied (i.e., conceptual design, embodiment design, and detail design). The detail design phase presents the most accurate and complete information regarding the product, while the conceptual design phase presents most generic data (e.g., functional information, product architecture). The third topic concerns the identification of future trends and challenges of DFMA methods in relation to the application field, product complexity, and design phase previously investigated.

On the other hand, in relation to the focused questions, the first topic refers to the DFMA method type, which can be quantitative or qualitative. A method is considered quantitative when it provides a numerical evaluation (e.g., the B&D DFMA method), while a method is qualitative when it provides suggestions and guidelines, not directly linked to numbers or mathematical equations (e.g., heuristics, guidelines). The second topic tackles the computational tool used to perform DFMA analysis. Three different types of tools were identified for this purpose: spreadsheets, software, and graph. The third topic analyses the application of advanced technologies with DFMA methods (i.e., the ones that currently characterize the enabling technologies of Industry 4.0).

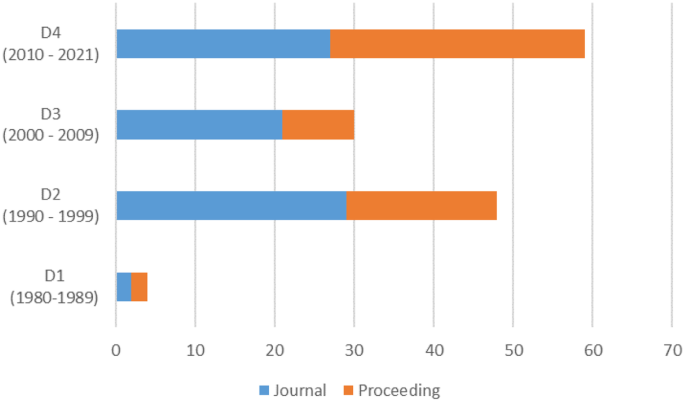

2.6 Bibliometric analysis

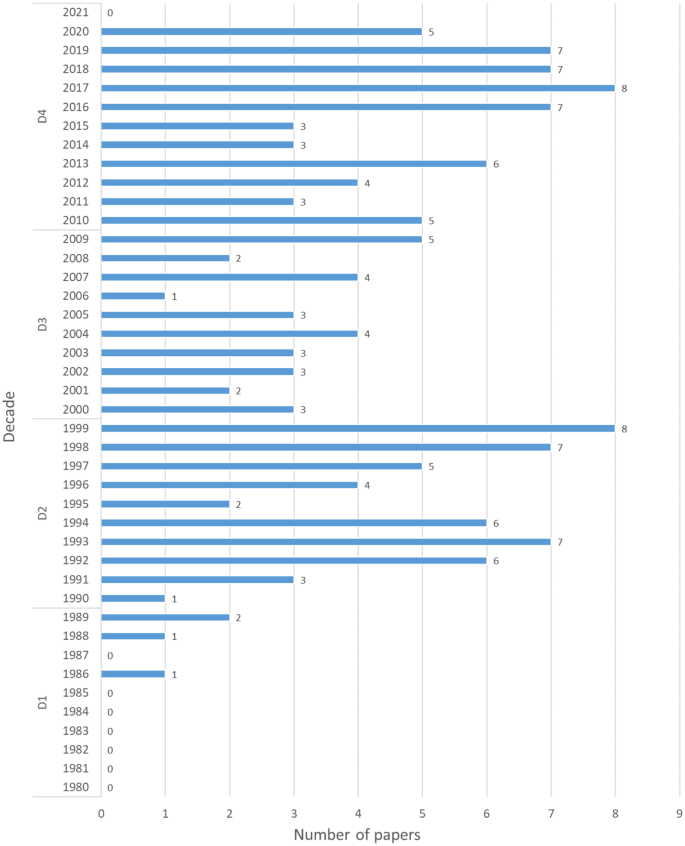

A bibliometric analysis was performed to understand when and where papers regarding DFMA methods have been published. The analysis was performed considering four decades, and the overall result is shown in Fig. 2 . An exception was made for the last decade (i.e., D4) which considers a time span ranging from 2010 to 2021 to include all the latest publications. The first decade includes only four papers and it appears to be the lowest in terms of publications, while the second decade presents a high number of papers (48). The third decade presents 30 papers published for the DFMA field, and finally, the latest decade presents the highest number of papers, which is 59. Although the graph shows a scattered distribution of papers, ranging from 0 to 8 for each year, the mean value for the last three decades is approximately 4.3. This result highlights a homogeneous distribution of paper over time about DFMA.

Number of papers vs. years

Both paper types published in journals and conference proceedings have been considered. Journals guarantee a stricter review process than proceedings following the time given to reviewers and the accessibility to scientific databases. Moreover, journals present more structured and mature research than conference proceedings. Additionally, a higher number of publications on conference proceedings indicate a considerable interest, since they present ongoing activities from different practitioners.

3 Results of the literature review

In this section, results of the literature review are presented following the two main groups of research questions previously identified.

3.1 Results related to the general questions

To answer the first general question, only papers in which a case study is presented have been analysed. The aim is to identify the industry’s field in which DFMA methods have been applied and the type of product analysed as a case study. On the other hand, to answer the second and the third general questions, all papers except reviews were considered. The aim is to understand in which phase DFMA methods are mainly applied, to identify the advantages/disadvantages of each design phase and to derive future research opportunities in the DFMA field.

3.1.1 Field of application and products analysed by DFMA methods

At the beginning of DFMA method development (early 1980s), articles were focusing on the conceptualization and description of DFMA methods, providing academic and exemplary case studies. During the 1990s, the application of DFMA methods in industries increased exponentially, particularly in the mechanical field. Starting from the second decade (D2), several case studies were provided to demonstrate the applicability of DFMA in mechanical and electro-mechanical products, and the same trend was confirmed in the following decades (D3 and D4). It is worth noting that most of the publications giving case studies have been implemented in the industrial field. The reason lies in the fact that several DFMA methods available in the literature are tested on generic products made of few components (i.e., dust filters, stapler, boiler) to validate the methods and their reliability. The number of papers presenting case studies in the automotive and aerospace fields is well balanced. Products analysed with DFMA methods are varying from sub-assemblies of a car (i.e., the suspension system, brake and clutch) to aircraft systems (i.e., pilot instrument panel, contactor assembly). Only a few articles tried to tackle the assemblability of a whole product; among them, Thompson et al. [ 23 ] tried to point out the relation between DFMA rules and late design changes in high-speed product development (i.e., circulator pumps for the commercial building services market). Gerding et al. [ 24 ] tackles the problem of implementing DFMA rules in long-lead-time products (i.e., aircraft), while Barbosa and Carvalho [ 25 , 26 ] proposed DFMA rules to optimize the assembly phase of an aircraft through re-design actions. Figure 3 shows the distribution of papers according to the type of product, the general field, and the specific field of application.

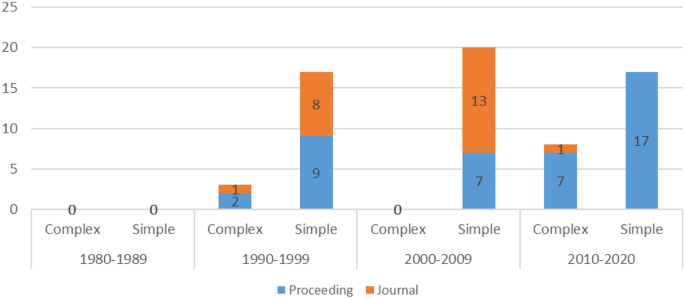

GQ1 data distribution

To understand the interest of the topic over time, the publications’ year was analysed together with the type of publication (i.e., journal or conference proceeding). Results of this analysis are summarized in Fig. 4 . Papers describing DFMA applications on both complex and simple products have increased over the years. It is interesting to notice that most of the articles proposing DFMA methods for complex products have been published in the last two decades (D3 and D4). This trend may be justified by several reasons. The first one concerns the fact that more and more industries are focusing on reaching a global improvement of their product, making the application of traditional DFMA challenging since the whole system must be considered. Another major factor in the development of DFMA methods for complex products concerns the increment of processing power that allows designers and engineers to handle a high amount of data in a limited timeframe, widening the boundary of their optimization problem from sub-parts to the whole system. The study of DFMA methods applied to simple products in the last three decades has increased as well. However, for the last decade (D4) most of the papers are published in conference proceedings and they present applications of already well-known DFMA techniques on different systems. Despite these works being useful to increase the number of case studies where DFMA methods are applied, they cannot be considered as research advancement in the DFMA methods. Other works published in conference proceedings are trying to extend DFMA principles in several ways. For example, Esterman and Kamath [ 27 ] attempted to apply DFMA to the improvement of assembly lines, Wood et al. [ 28 ] and Nyemba et al. [ 29 ] provided new design rules to cope with constraint production of the developing countries, and finally Favi et al. [ 2 ], Hein et al. [ 30 ], and Gupta and Kumar [ 31 ] included new principles and criteria for multi-objective analysis (i.e., cost, sustainability).

Distribution of papers per decade in relation to simple and complex products

The overall data collected about this topic are summarized in Table 7 in the Appendix . From the performed analysis, DFMA methods have been mainly applied on simple products or sub-assemblies, in which all parts are made with traditional production technologies (i.e., fusion, sheet metal stamping and bending, forging). DFMA analysis evaluates assembly solutions adopted in the analysed products. Assembly solutions are generally bolted joints, more rarely welded or riveted joints. The main goal of these analyses is to understand if it is possible to reduce the number of components which, typically, leads to a reduction of assembly time [ 19 ]. As an outcome, the typical product analysed using DFMA techniques is a simple product assembled manually with bolted joints made of less than 60 parts. Another interesting result concerns the fact that sub-assemblies are considered rather than the whole product. This result leads to the application of DFMA methodologies in a limited context (i.e., the companies which are designing and manufacturing sub-assemblies) making effective the benefits of DFMA for suppliers. In this scenario, each module (sub-assembly) is assembled with a specific assembly technology, making the overall analysis easier to manage. For instance, a car engine is assembled with bolted joints and chassis are assembled with welding technologies. If the assembly technology varies, then the DFMA analysis becomes more challenging and, consequently, the overall final improvement might not have an elevated positive impact as the sub-systems improvements might have.

3.1.2 Product design phase challenged by DFMA methods

According to Pahl et al. [ 32 ], the PDP process can be divided into conceptual design, embodiment design, and detail design. For each phase, different information and tools are available to support designers in the definition of the product. The conceptual design phase represents the initial phase of the product development process, in which only general information (e.g., product functions, product architecture) is available. The embodiment phase represents a more mature phase of a project in which a preliminary product layout is available. Generally, this design phase is linked with the use of 3D CAD drawings. Finally, the detail design phase represents the step with a higher level of detail. Specific information is available at this phase, such as the number and type of screws, assembly procedures, assembly sequence, and takt time. In this phase, detailed drawings are made to fully describe the product for the manufacturing process. Together with the information granularity, also the cost of changes varies according to the design phase in which modifications are introduced. With the aim to analyse this topic, all papers except reviews have been considered. The analysis of the literature shows that DFMA methods are mainly used during detail and embodiment design phases (Table 7 in the Appendix ). Indeed, considering the most spread DFMA methods (i.e., B&D and Lucas method), the analysis is performed starting with detailed design information. Among the analysed papers, a large part of them tried to use DFMA methods at the embodiment phase by reducing the need for specific information. For instance, Sanders et al. [ 33 ] proposed a knowledge-based system to optimize products without detailed information, while Samadhi et al. [ 34 ] tried to develop a fully automated DFMA method, linked to a 3D CAD modeller, enabling to extract data related to the product under development. The application of DFMA methods at the late design phase is in line with the idea of DFMA since most of the methodologies have been developed as a systematic approach, whose aim is to optimize the product through different design iterations (incremental improvement through product re-design). However, several problems arise working at the late design phases such as the high cost of change. Since the beginning of the advent of DFMA methods, some studies tried to move the analysis from the detail design phase to the conceptual design phase. Among these, the paper proposed by Rampersad [ 35 ] was one of the first to investigate DFMA methods from a relational point of view, to understand how design variables affect product assembly. A more recent attempt was performed by Emmatty and Sarmah [ 36 ] that tried to merge DFA and DFM techniques with product architectures analysis. Across the collected works, only two works proposed to integrate the TRIZ methodology and the DFMA to widen the solution space, which is a typical task of conceptual design [ 37 , 38 ]. The typical output of DFMA methods in the conceptual design phase is a product architecture with optimized performance in terms of assembly. Functional modules, interconnections, and related parameters are considered in the DFMA analyses to identify installation and assembly issues. For instance, the position, the attachment points, the overall number of the functional modules, and/or the interface route among modules are some of the parameters considered in the developed DFMA methods conceived for the conceptual design phase. Hence, DFMA analysis performed at the conceptual design phase focuses on the module rather than the physical components and provides product optimization through module arrangement and layout inside the product (i.e., product architecture). When DFMA analyses are conducted at the detail or embodiment design phase, the typical output is again a product with optimized assembly performances, but the focus concerns the components/parts. DFMA tools aim at improving the product assemblability by reducing the overall number of components, minimizing the number of fixations (i.e., screws, rivets), standardizing the type of fixations, reducing the part re-orientation during the manual operations, and choosing the most appropriated manufacturing technology among others. Hence, DFMA analysis performed at the embodiment/detail design phases focuses on the physical component providing a product optimization through the improvement of component shape, features geometries, and manufacturing aspects. It is interesting to notice that in the last decade, the efforts to propose DFMA methods applicable at the conceptual design phase have been increased for both simple and complex products.

3.1.3 Future challenges to address by using DFMA methods

From the extracted data, most of the papers are dealing with the improvement of simple products at the detail design phase. The analysis shows also how the DFMA evolved integrating new objectives (e.g., ergonomic and environmental aspects) and multi-attribute analysis. On the other hand, the research activity related to DFMA methods shifted towards the analysis of complex products, and an increased interest in the conceptual design phase was noticed. To cite a few, Remirez et al. [ 39 ] tried to adapt the B&D DFMA methodology to tackle the assembly issues of a solar tracker, while Mora et al. [ 40 ] adapted the design structure matrix method to work with large size products (i.e., elevators, wind turbines, solar plants, pilot plants, or petrochemical facilities). With the same aim Formentini et al. [ 41 ] provided a method to collect design guidelines to optimize the aircraft architecture at the conceptual design phases. The transition of DFMA analysis towards the early design phases emerged as a trend to be investigated in future years. This trend emphasizes the need to shift the DFMA paradigm by establishing a systematic optimization method that may be used at the conceptual stage, when degrees of freedom are larger, to achieve the right first time design [ 19 ], before moving on to the later design phases. Another aspect that characterizes DFMA studies of products with a certain complexity is the high number of data required for the analysis and computational time needed to perform the analysis. To summarize the outcome of the literature analysis, an increasing interest in the development of DFMA methods for complex products is raising in the scientific community. However, there is no evidence stating that DFMA methods provide better benefits to complex rather than simple products. Based on the revised papers, a high number of manuscripts presented applications of DFMA methods on simple products. This trend may be justified by the fact that on simple products, DFMA results can be validated and tested through product prototypes. Moreover, the application of DFMA analysis on simple products is in line with the concept of incremental innovation. In this respect, DFMA techniques were applied to product sub-systems (or sub-assemblies, which indirectly provides an overall optimization of the product. The application of DFMA analysis on the entire product, especially when it is complex, may generate different outputs and might lead to radical innovation in terms of assembly performances. To date, there is no evidence about a direct comparison (e.g., DFMA index assessment between a complex product developed with DFMA criteria and the same product in which the DFMA principles were applied to sub-assemblies. This lack lies in the needs of industry where usually sub-systems are provided by different suppliers,thus, there is no interest in investigating the product assemblability as a whole system. This perspective is currently not addressed within the literature and represents an opportunity for further research. Another upcoming challenge for DFMA is the need to integrate DFMA analysis with other design aspects (multi-objective analysis, creating engineering design methodologies that consider multiple aspects. For instance, ergonomic analysis is important to guarantee the assembly optimization of the product. Boothroyd [ 19 ] already considered the ergonomic aspect in his approach,however, it was considered in relation to the operator in the assembly line, where small products are handled. Moving towards bigger and complex products, the assembly process requires the operator to actively adapt to the working space and environment, and different ergonomic parameters need to be considered, such as working position, the access to the place where activities are performed, and ergonomic operator posture among others [ 42 ].

3.2 Results related to the focused question

To answer the focused questions, only a proper subset of papers was analysed for each topic with the aim to explore specific aspects related to the type of DFMA methods. These specific topics concern the type of tools used for the analysis, as well as the enabling technologies used to implement DFMA in modern industries.

3.2.1 Qualitative vs. quantitative DFMA methods

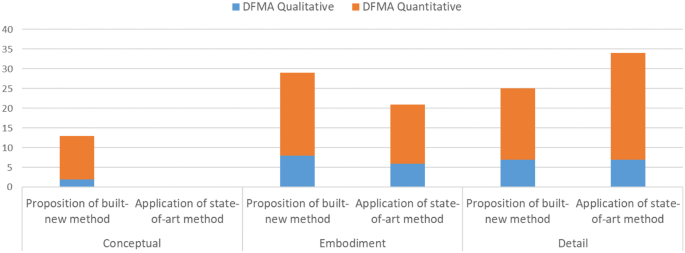

DFMA methods can be clustered into different categories: qualitative and quantitative. A method is considered quantitative when it provides numbers and indicators (i.e., metrics) to evaluate the goodness of a product from the assembly and manufacturing point of view. According to this definition, quantitative methods have been widely used as engineering design tools [ 11 ]. An example of the DFMA quantitative method is the B&D method. On the other hand, a method is considered qualitative when it provides an evaluation of the product manufacturability and assemblability using design practice derived from experience. Qualitative methods are usually providing design suggestions, rules, and guidelines without the adoption of numerical metrics. Dealing with the study of qualitative vs. quantitative DFMA methods, the analysis was performed looking at all papers except the reviews and papers oriented to the plant management. Results show that three quarters of the papers are proposing quantitative approaches, while only a one quarter studied qualitative approaches. Among all, only two papers tried to provide a method that can be considered both qualitative and quantitative [ 43 , 44 ]. Table 5 reports the main types of information required to perform DFMA analysis, in relation to quantitative and qualitative methods. Despite some inputs being shared among quantitative and qualitative methods (e.g., number of parts), the main outputs are different.

From the performed analysis, the most-used inputs for DFMA indices are assembly time (s), material cost ($), and number of parts (#). DFMA indices for quantitative methods have all the same root, which is providing a score based on the identified product parameters (input data). According to the type of parameters and the developed method, the DFMA index can assume a different meaning. For instance, the most popular DFA index from the B&D approach (also known as design efficiency) is computed by the following equation [ 19 ]:

NM = theoretical number of parts is an estimation concerning the number of essential parts of the product derived by the optimization process proposed by the method,

TM = total assembly time is the overall assembly time of the product measured with experimental tests.

The DFA index gives an overall assessment of the product assemblability performance (dimensionless index). The DFA index can be applied to different products, and it is based on values derived from standardized tables. Differently from DFA index, the total grade indices allow considering both DFA (total grade of the assembly) and DFM (total grade of the part) [ 45 ]. The method identified a list of product parameters for the manufacturing assessment (billet, work material, features, machine accessibility, etc.) and for the assembly assessment (i.e., billet dimension, part handling, assembly fixtures, tolerance and clearance) providing a weight for each parameter (from 0 to 10). Following a value engineering approach, a score of 0 is assigned if the parameter is not critical for the manufacturing/assembly, while 1 is assigned if the parameter affects the manufacturing/assembly process. Total grade indices are obtained by multiplying the weight of each parameter with the score associated with the considered parameter and finally by making an overall sum. The lower the total grade of the part and the assembly is, the more efficient the product is from the manufacturing and assembly perspectives. Both DFA index and total grade of the assembly/part are quantitative.

Regarding qualitative DFMA methods, the general outcome is a list of items (i.e., rules, graph, guidelines) in which design suggestions to improve product manufacturability and assemblability are collected. For instance, the design structure matrix (DSM) is a well-known tool to represent product architectures. DSM representation helps designers to create products with enhanced manufacturing and assembly properties. Qualitative DFMA methods can also provide a performance index, which is used to assess the improvement obtained by the implemented design actions. According to the method used, the performance index is derived using different inputs (e.g., the initial number of components/final number of components, initial cost/final cost) and it provides a rough estimation of the benefits introduced by the implementation of the design guidelines.

Regardless the fact that a DFMA index is quantitative or qualitative, the analysis showed that DFMA indices can be divided into two groups: time-based and feature based. Time-based DFMA indices rely on tables to convert time-related assembly parameters into scores. Tables are derived through extensive experiments. The main drawback of these indices is the complexity to personalize these tables on a specific product (e.g., complex products). On the other hand, feature-based DFMA indices rely on tables to convert assembly-related features into scores. Tables are derived through knowledge formalization techniques. These types of indices allow personalising tables on the product analysed but require a great effort to be set up and they may be subjected to bias. As an outcome of the literature review, the definition of a general DFMA index which can be adopted for every type of product or system can present several issues. A trade-off among analysis accuracy, available time, and availability of data must be reached and the proper DFMA index selected accordingly.

Another interesting area of investigation regards the type of DFMA method versus the design phase at which it is used. Figure 5 presents the data collected from the analysis of the qualitative/quantitative DFMA methods versus the design phase.

Distribution of quantitative and qualitative methods in relation to the design phase

Quantitative methods appear to be widely used at the late design phase. This result is in line with the available information, which is mainly numerical. Moving towards the early design phase (i.e., conceptual design), a great effort was done to develop new methods to study manufacturing and assembly aspects with less information. Among the DFMA methods focusing on the early stage of the design process, the majority of them are quantitative. This is an interesting outcome since no quantitative information is available in this design phase. For instance, Jung and Billatos [ 46 ] examined some elements of intelligent design systems to assess manufacturability of a product through the development of a knowledge based expert system for assembly. The knowledge base has been acquired from design for assembly along with axiomatic design concepts with emphasis on the conceptual design stage where the structure of the product as a whole is considered. Dagman and Söderberg [ 47 ] proposed to use axiomatic design principles to analyse and improve product architecture by the assessment of manufacturing, assembly, and disassembly parameters during the early design phase. Both methodologies, which are based on axiomatic design, are quantitative and use matrices to link functional requirements with design parameters. Favi et al. [ 48 ] proposed a method to perform a multi-objective optimization in terms of assembly, materials, processes, costs, and times at the conceptual design phase. The analysis was performed at the product architecture level, using product modules and design solutions derived with the help of the morphological matrix. In the mentioned work, all parameters required for performing the DFMA analysis were supposed from an already existing product. A similar approach was proposed by Formentini et al. [ 41 ], Favi et al. [ 49 ], and Bouissiere et al. [ 50 ] for the study of product architecture assembly performances for systems installation of a commercial aircraft.

3.2.2 Tools used to support DFMA methods

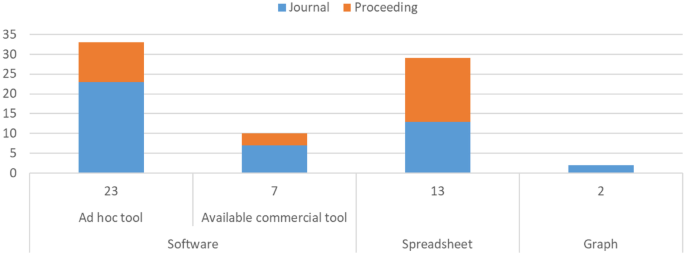

Concerning the development of engineering tools able to support the DFMA analysis of mechanical products, only a subset (74) of papers addressed this topic. Three different types of tools were identified by the analysis of the literature: graph, software, and spreadsheets. Each tool was further classified according to the aim of the analysis: (i) redesign suggestions, (ii) guidelines collection, (iii) metrics computations, and (iv) method integration. Redesign suggestions tool allows at the identification of redesign actions to improve the assemblability and manufacturability of the product under analysis. Guideline’s collection tool aims at transforming implicit knowledge into explicit one. Metric computation tool consists of the automatization of the computation of assembly and manufacturing parameters, and method integration tool describes the link with other engineering methods (i.e., FEM analysis). From the performed review, a dedicated software system is the main used tool, followed by spreadsheets and graphs (see Fig. 6 ). By the analysis of the type of software, research works presenting case studies are more willing to use commercial DFMA software (e.g., B&D commercial software) than an ad hoc developed software tool. Among commercial software tools, most of them were developed for metrics computations (i.e., assembly time, required assembly steps). The same trend is noticed for the spreadsheets. Only two papers are making use of graphs as tool for DFMA analysis. For example, Wu and O’Grady [ 51 ] suggested to use Petri-Nets to model CE aspects and make the application of DFMA techniques leaner, while Hsu and Lin [ 52 ] used graphs to integrate DFA, assembly functional presentation, and problem recommendation–driven mechanism. According to the performed analysis, spreadsheets and ad hoc software appear to be the most used tools. The use of spreadsheets lies in the accessibility and straightness in their use. They are the best choice when a method is not consolidated and only a few analyses were performed. Additionally, the software has been widely used to implement the DFMA method. Two types of software have been identified in the analysis: (i) ad hoc developed software and (ii) commercially available software. Generally, the development of software implies a greater effort in terms of time than commercial software or spreadsheets. The commercial software tools identified during the review concern both design tools and simulations tools (i.e., DFMA ® Boothroyd Dewhurst Software, Tecnomatix Dynamo, and Flexible Line Balancing Software). In other cases, the analysis was performed retrieving information from CAD tool, but no information was provided regarding the DFMA software used [ 53 , 54 ]. Moreover, it is interesting to analyse the use of tools versus the type of publication. Figure 6 shows that the use of spreadsheets is higher in the conference proceeding publications than the journal ones. Spreadsheets are mainly used to perform isolated analyses, while ad hoc software tools were developed to include methodological aspects within the novel DFMA framework which are more suitable for journal publications. Table 7 in the Appendix reports a summary of the outcomes related to this topic.

Tool vs. number and type of publication

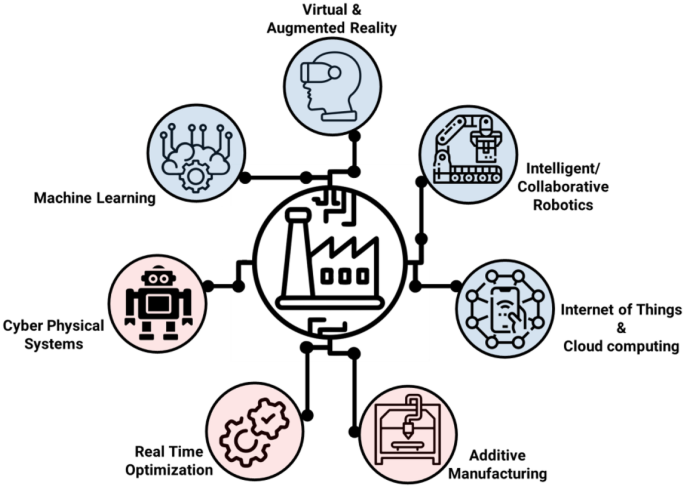

3.2.3 Industry 4.0 enabling technologies challenging DFMA methods

The advances in Industry 4.0 provide both challenges and opportunities for digital manufacturing and assembly systems. Industry 4.0 aims at the development of a new generation of smart factories grounded on the manufacturing and assembly process digitalization. Most of the Industry 4.0 enabling technologies are related to digitization, data management, and connectivity, and they are dependent on solid data acquisition technologies. For the purpose of this review, not all the enabling technologies have been considered (Fig. 7 ) due to different reasons.

Enabling technology for Industry 4.0 (blue included in the review; red excluded)

The “additive manufacturing” technology was not studied since design methods called “design for additive manufacturing” have been specifically developed to consider this technology and they are not the goal of this review. The interested reader can find further information regarding DFAM methods in the review proposed by Wiberg et al. [ 152 ]. “Real-time optimization” and “cyber-physical systems” were not considered since they are mainly focusing on plant management rather than product design. For the aim of this review only “machine learning and AI,” “virtual and augmented reality,” “intelligent/collaborative robotics,” and “Internet of Things and cloud computing” were examined. In addition, a more detailed list of tools was identified for the technology “machine learning and AI,” including (i) expert system, (ii) fuzzy logic, (iii) genetic algorithm, and (iv) constraint-network approach. Among all the papers, only a few papers addressed the technology “machine learning and AI” proposing the use of the mentioned tools for the development of DFMA methods. The common goal of the analysed works is to eliminate the need for expertise to perform an assembly oriented design choice. The use of mathematical artefacts (e.g., artificial intelligence, genetic algorithms, expert system, fuzzy logic) allowed the collection of existing knowledge and the development of an automated system for knowledge sharing. Referring to the technology “virtual and augmented reality,” the idea was to use this technology in helping designers with the mock-up creation at the embodiment design phase facilitating the analysis of assembly operations (i.e., ergonomics). As regard the technology “Internet of Things and cloud computing,” only two discussed the applicability of these technologies for the DFMA analysis. Both manuscripts tried to move DFMA analysis in a cloud environment to get access to more case studies, more data, and the possibility to share assembly/manufacturing knowledge on past projects. Finally, even though there are several papers presenting methodologies to consider automatic assembly, no papers were found for the technology “intelligent/collaborative robotics.” Automatic assembly was generally not analysed through the means of DFMA, and the design of robotic cells and lines is usually customized to build a specific product and/or product family [ 104 ]. Industry 4.0 technologies brought a new paradigm for industries and manufacturing companies including a different way to collect, process, and elaborate data, as well as the production of customized products. The idea ground pinning the adoption of these technologies for DFMA purposes is to reduce the risk of implementing wrong design actions, and it helps to select the right modification among a pool of options. For example, Internet of Things can support DFMA analysis collecting data through several sensors placed directly on the product or the assembly line. Machine learning techniques can make use of past data, and the analysis of implemented design actions to suggest the right design action to implement in a given time. Machine learning processes can be used also to drive the product optimization following a multi-objective analysis to address different design goals (i.e., DfX). The cloud computing can open new possibilities in terms of data sharing by using virtual servers to collect and process data. The idea of cloud computing is in line with the concept of open manufacturing introduced by Kusiak [ 153 ] allowing different stakeholders to share data and optimize the manufacturability of their products in different contexts and countries.

As previously introduced, virtual and augmented reality can enable the investigation of ergonomic aspects during the assemblability process and the optimization of manual assembly operations. Exploring the product in a virtual environment, it is possible to highlight ergonomic issues (i.e., wrong operator position, impossibility to access to a particular product area) and solve them before the product is finalized. Moreover, operators can be trained before the product is physically available, reducing the time required for the in-process learning curve, cost of training, and consequently time to market.

By following the bibliometric analysis, the majority of works introducing Industry 4.0 enabling technologies are dated in the second and the third decades (D2 and D3). At that time, the concept of Industry 4.0 had not yet been formalized; therefore, all these studies can be considered as preparatory for the paradigm shift brought by the advent of Industry 4.0. When the concept of Industry 4.0 was introduced (beginning of 2010), the application of enabling technologies in relation to manufacturing and assembly aspects took a different research angle (from the product to the production site, i.e., plant management and production). This outcome has been validated by performing quick research with keywords “Industry 4.0 Design for Assembly” on main scientific databases. The retrieved papers are not focused on the design aspects of product assemblability anymore, but rather on the management of the assembly line and production site. In conclusion, traditional DFMA methods were not deeply investigated in relation to the Industry 4.0 enabling technologies.

4 Limitations

The literature analysis performed and presented in this paper shows few limitations that may affect the scope of the results and deserve to be introduced. The research process was performed systematically, identifying parameters and criteria to mitigate possible bias. The main limitation is identified by the adoption of a filtering process which uses criteria defined by the authors. For example, the exclusion criteria SC1 (articles not available for download) is not scientific and repeatable. In fact, according to the type of database and the institution’s accessibility, some articles excluded by the authors may be available for other users. In addition, this review focuses on scientific articles (both journal and conference papers), not considering, for example, thesis, book chapters, technical reports, commercial tools, and patents. Since DFMA is considered an applied science in the field of engineering, some interesting works developed outside the boundaries of the academic community could be excluded from this analysis. Finally, due to the high number of articles found, no other sampling techniques (e.g., snowball sampling) have been used to derive articles other than the one described.

5 Discussion

Through the analysis of the results related to general questions, it is possible to draw a discussion about the DFMA research done during the years. The critical analysis of results showed that DFMA methods have been mainly used for products made of few components and assembled with the same technology (i.e., bolted, welded). This outcome is in line with the idea of the early DFMA methods (e.g., Lucas, B&D) where an analysis of the assembly process is required for a given product to understand if can be optimized by eliminating/merging parts. Another interesting result considers the area in which DFMA methods are applied. Since this review is focused on DFMA methods for mechanical products, most of the presented case studies refer to the mechanical and electro-mechanical fields. In this scenario, only a few papers tried to tackle complex products (i.e., long lead time, heavy products, and characterized by a high number of parts). Several limitations were observed when a traditional DFMA method is applied to complex products such as the management of a high number of information as well as the inconsistency between manufacturability and parts integration which is the cornerstone of the DFMA.

The critical analysis of results in relation to the focused questions showed that regardless of the design phase at which DFMA methodologies were implemented, a continuous effort to derive quantitative methods was done since the beginning. Quantitative indices allow determining the performance of manufacturability and assembly for decision-making purposes. In addition, the use of numerical indices leads to a possible comparison between design alternatives, assessing the benefits introduced by novel design solutions. It was observed that the use of metrics and indices is suitable for the late design phases (embodiment and detail design) when numerical parameters are available with lower uncertainty. On the other hand, the assessment of quantitative results during the early phases of the PDP (conceptual design) requires defining specific boundaries and criteria for the field of interest. This limitation may affect the design solution space and the overall optimization process. This result leads to an open question “Is it possible to create quantitative DFMA methods applicable at the conceptual design phase, without limiting the available solution space?”.

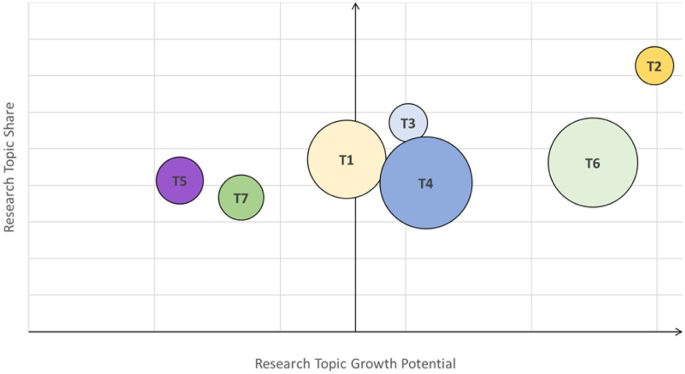

The bibliometric study revealed the evolution of DFMA approaches’ interest through time (Fig. 8 ). The analysed works covered both conference proceedings and journals, showing an active interest in the subject by industries and academia. Results show that D2 and D4 present the highest production of papers. For the D3 decade, it seems that the interest in the DFMA subject decreased. This trend is primarily caused by the change of topics and paradigms associated with DFMA, creating a pool of methods very similar but with different names (i.e., installation, system integration, design for additive manufacturing). In the recent decade (D4), there was a rise in the overall number of publications compared to the previous periods. The reason may be the increase in publication rate in the scientific world; indeed, the National Science Board reported a study showing that the global research output grew about 4% annually over the last 10 years [ 154 ]. In conclusion, it is hard to claim that the research interest in DFMA methods increase in the last decade compared with the previous ones.

Overall distribution of papers (journal and conference proceedings) per decades

A map was developed utilizing a bubble graph to analyse and show interest in the DFMA issue through time and discover future trends (Fig. 9 ). The considered topics are collected in Table 6 .

Bubble graph results (research topic share vs. research topic growth potential)

The size of the bubble represents the total number of publications for each topic during the period under consideration (i.e., decade D4). The Research Topic Share (RTS) is computed considering the overall number of papers divided for the number of papers of the last decade for a given topic. The Research Topic Growth Potential (RTGP) was computed by applying the least square method in relation to the number of publications per topic and year of the last decade (i.e., decade D4).