To read this content please select one of the options below:

Please note you do not have access to teaching notes, craft beer – a systematic literature review and research agenda.

International Journal of Wine Business Research

ISSN : 1751-1062

Article publication date: 3 November 2021

Issue publication date: 5 May 2022

In recent years, the craft beer (CB) industry has gained impetus and has experienced significant growth in scientific publications. This study aims to present a systematic review of the literature on CB in areas related to economic and business sciences.

Design/methodology/approach

Based on the data from Scopus, Web of Science and a set of articles not indexed to these databases until June 2021, a total of 132 articles were included for analysis, using bibliometric and content analysis techniques.

The study allowed us to identify that CB has four main clusters/themes of research, namely, CB industry and market, marketing and branding, consumer behavior and sustainability. Detailed information on the clusters is provided. In addition, the results showed that publications addressing CB have grown significantly from 2015 onwards and are dispersed across many journals, with none assuming a clear leadership. Quantitative approaches account for more than half of publications.

Research limitations/implications

This study is a useful guide for academics intending to develop studies with CB. It provides a framework to structure future research by identifying existing literature clusters and proposes several research propositions.

Practical implications

The findings from this study are useful for CB companies to get an overview of the main issues affecting the CB industry and market to be able to adapt their strategies and stay aligned with market tendencies in the four main clusters identified.

Originality/value

This is the first systematic review of CB. Therefore, it provides a significant contribution to frame and strengthening the literature on CB and serves as a reference for future research. Based on the content analysis and cluster identification, the findings portray the status of current research. Accordingly, a set of research opportunities are offered.

- Consumer behaviour

- Globalization

- Systematic literature review

- Conceptual/theoretical

Acknowledgements

The authors thank NECE-UBI, Research Centre for Business Sciences, Research Centre funded by FCT – Fundação para a Ciência e a Tecnologia, IP, under the project UIDB/04630/2020.

Nave, E. , Duarte, P. , Rodrigues, R.G. , Paço, A. , Alves, H. and Oliveira, T. (2022), "Craft beer – a systematic literature review and research agenda", International Journal of Wine Business Research , Vol. 34 No. 2, pp. 278-307. https://doi.org/10.1108/IJWBR-05-2021-0029

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

All feedback is valuable.

Please share your general feedback

Report an issue or find answers to frequently asked questions

Contact Customer Support

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > New Advances on Fermentation Processes

Craft Beers: Current Situation and Future Trends

Submitted: 13 February 2019 Reviewed: 02 October 2019 Published: 27 November 2019

DOI: 10.5772/intechopen.90006

Cite this chapter

There are two ways to cite this chapter:

From the Edited Volume

New Advances on Fermentation Processes

Edited by Rosa María Martínez-Espinosa

To purchase hard copies of this book, please contact the representative in India: CBS Publishers & Distributors Pvt. Ltd. www.cbspd.com | [email protected]

Chapter metrics overview

1,922 Chapter Downloads

Impact of this chapter

Total Chapter Downloads on intechopen.com

Total Chapter Views on intechopen.com

Overall attention for this chapters

During the twentieth century, the consolidation of large multi-national beer companies and the homogenization of the specified beer types have led to a considerable growth in the beer industry. However, the growing demand by consumers of a single and distinctive product, with a higher quality and better sensory complexity, is allowing for a new resurgence of craft beer segment in recent years. This chapter reviews some different alternatives of innovation in the craft brewing process: from the bottle fermented beers with non-Saccharomyces yeast species, to the use of special malts or specific adjuncts, hop varieties, water quality, etc. All of them open a lot of new possibilities to modulate flavor and other sensory properties of beer, reaching also new consumers looking for a specific story in one of the oldest fermented beverages.

- non-Saccharomyces

- new adjuncts

- bottle fermentation

Author Information

María jesús callejo *.

- Universidad Politécnica de Madrid, Spain

Wendu Tesfaye

María carmen gonzález, antonio morata.

*Address all correspondence to: [email protected]

1. Introduction

Beer brewing is an established ancient art in different civilization and cultures, but there is no a precise and unanimous agreement on the origin of beer. Recent evidences predominantly based on the archeological and historical evidences explain the origin of brewing across time and space [ 1 ]. The timespan for its existence differs over a wide range of geography, from as far back as “The Neolithic Revolution” to the early horizon in South America. It commenced in the agricultural or “Neolithic” revolution period as early as 9000 BC with the advent of the Sumerians in the lowlands of the Mesopotamian alluvial plane [ 2 , 3 ]. Evidence of rice-based fermented beverage has been found in between 7000 and 5000 BC in China [ 4 , 5 , 6 , 7 ] and ancient Mesopotamia back to about 6000 BC [ 8 , 9 , 10 ]. Similarly, in Northern Africa highlighting Egypt at about 3500 BC [ 11 ], in Europe around 3000 BC [ 12 , 13 ] and in South America 900-200 BC [ 14 , 15 , 16 ], locally fermented alcoholic beverages have been produced. Recent starch [ 17 ] and chemical residue studies [ 18 ] extend this period as far as 11,000 BC. In broader terms, all these fermented beverages may be considered as a craft beer based on the production scale.

2. Craft beer: as a movement from bottom to top fermentation. The reemergence of craft brewing

Different cultures and different civilization historically produced a number of fermented beverages/beer with different raw materials, which allowed them to have different attributes and different names. Beer is a relatively simple fermented product, mainly water in its composition, which makes easily produced locally; however, for a long time the difficulty to move long distances permits to flourish craft brewers everywhere in the world [ 19 ]. However, at present, it is not an impediment due to technological advances and transportation progress.

The craft beer movement or revolution began in the USA after the 13 years of national prohibition of alcohol or “the noble experiment” 1919–1933. In 1965, Fritz Maytag, the man of the craft beer renaissance, bought the Anchor Steam Beer Company of San Francisco with a capacity of 50,000 barrels and developed it as a craft brewery outlet [ 20 , 21 ]. Regarding the USA, this was the milestone to the expanding innovation and an increasing trend in terms of production and sales of beers with differentiated quality.

Even though this movement marked a shift in several countries recently, to mention some, in 1988 the earliest brewpub lay foundation in Italy [ 22 ], while in the Netherlands the craft revolution rouse during the year 1981 [ 23 ], in Australia, craft brewing started late 1984 [ 24 ]. At the same time, it is very difficult to put a time limit for the beginning of craft beer production in some European countries like the UK, Belgium and Germany where these countries were either with a long tradition in “special beers” or the historical existence of small and local producers back to the 1970s [ 25 , 26 ].

3. Craft beer: statistical viewpoint

One of the indicators for the expansion of craft beer renaissance in different countries is the statistical approach. However, there is no common shared definition of craft beer but different associations and entities of different countries remark based on the size of the firm, production volume raw materials used to produce such drink, degree of independence and way to brew [ 27 ]. Even though there is data scarcity on the numbers of microbreweries of different countries, in Table 1 , those microbreweries actually existing in different countries of the five continents are represented, where beer production is traditional or its consumption is highly relevant at present. The statistical data reflected in this chapter encompasses all beer producers recognized as craft brewery, artisanal brewery, microbrewery, independent brewery, specialty brewery, Brewpub, local brewery, Regional brewery and Contract brewing company in accordance with the regulation rules of different countries without establishing any distinctions among them.

| 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Europe | 1755 | 2123 | 2407 | 2670 | 3094 | 3616 | N/A | N/A | N/A | N/A |

| Czech Republic1 | 57 | 51 | 65 | 90 | 20 | 207 | 238 | 202 | 350 | 402 |

| France1 | N/A | 263 | 322 | 373 | 293 | 504 | 566 | 690 | 850 | 1000 |

| Germany1 | 594 | 628 | 646 | 659 | 665 | 668 | 677 | 723 | 738 | 824 |

| The Netherlands | N/A | N/A | 115 | N/A | N/A | N/A | 222 | 380 | 434 | N/A |

| Poland | 79 | 89 | 107 | 133 | 164 | 212 | 263 | 308 | N/A | N/A |

| Spain | 21 | 27 | 46 | 70 | 114 | 203 | 314 | 409 | 465 | 502 |

| The UK | 671 | 694 | 778 | 898 | 1250 | 1440 | 1414 | 1828 | 2198 | 2378 |

| America | ||||||||||

| The USA | 1321 | 1596 | 1754 | 2016 | 2420 | 2898 | 3739 | 4544 | 5424 | 6266 |

| Canada | N/A | N/A | 277 | N/A | N/A | N/A | N/A | 610 | 612 | N/A |

| Africa | ||||||||||

| South Africa | 22 | 22 | 27 | 34 | 54 | 63 | N/A | N/A | N/A | N/A |

| Asia | ||||||||||

| Japan | N/A | N/A | 208 | N/A | N/A | N/A | N/A | 222 | N/A | N/A |

| Oceania | ||||||||||

| Australia | N/A | N/A | 172 | N/A | N/A | N/A | N/A | 358 | 410 | N/A |

| New Zealand | N/A | N/A | 62 | 59 | 65 | 79 | 98 | 111 | 130 | N/A |

Microbrewery expansion in the last decade sample countries by continent.

[ 24 , 26 ].

Even though Mergers and acquisitions seem to reduce the number of major brewing firms, the total production in volume is not affected. This tendency provides an opportunity to the merged breweries to take advantage over the microbreweries in terms of economical scale and increased market share. Despite the macrobrewers dominance, worldwide craft beer numbers are increasing at a rapid rate [ 28 ].

4. New tendencies: is the glass half-full or half-empty for brewers?

The last two decades brewing landscape continues to rise in number of micro and craft breweries almost everywhere in the world. As it is shown below ( Table 1 ), in the last decade, from 2008 to 2017, the number of craft breweries significantly increased globally. In fact it passed from 671 to 2378 in the UK (traditionally beer-producing and beer-drinking country), and from 1321 to 6266 in the USA, an increase of 354 and 474% respectively, within the same period (not traditional beer producer country). This increase in number of craft breweries and production volume run up to an increase in compound annual growth rate (CAGR) within the sector. Craft brewing continues to take market share away from the largest brewing companies. According to Brewers Association report (the U.S. beer sales volume growth 2017, National beer sales and production statistical data), the overall U.S. beer volume sales were down 1% in 2017, whereas craft brewer sales continued to grow at a rate of 5% by volume, reaching 12.7% of the U.S. beer market by volume. Craft production grew the most for microbreweries. Retail dollar sales of craft increased 8%, up to $26.0 billion, and now account for more than 23% of the $111.4 billion U.S. beer market [ 27 ]. Percentage of craft beer producers (2013–2017) can be seen in Figure 1 .

Percentage of craft beer producers (2013–2017).

There are various factors, which favored this increase in overall craft beer consumption. These factors include per capita income growth, the availability of alternatives toward the production of successful and high levels of quality beers, increased health concerns, and the emergence of new government regulations that affects directly the sustainability issue and consistency and innovation among many others.

5. Craft and special beers: classification

A single beer style, lager beer, has long been the main dominant beer in the world market. However, a worldwide change in trend for the last decade has been registered due to the growing interest in craft and specialized beer [ 34 ]. A significant growth in the number of breweries, the variety of styles and the total volume of production had been observed in previous years [ 35 ].

But the reasons for the growth are multiple: first, increase in the demand for high more flavorful and stronger beers [ 34 , 36 ]. This is particularly important in the case of American consumers, often not satisfied with the dominant in the market American pale lagers. An increase in flavors (malted barley, chestnut, honey flavored) and a more readily quality perceived are the main factors to choose craft beer instead of commercial beer between habitual beer drinkers [ 37 ]. Second, exclusivity and “unique drinking experiences” are also highly rated by craft beer consumers [ 34 , 38 ]. Finally, even though traditional brands of beer are closely linked to very specific places [ 39 ], craft beer is part of a broader neolocalism movement in which people are demanding goods and services that have a connection with the local community [ 36 ].

Taking into account that all beer types evolve from the combination and relationships among ingredients, processing, packaging, marketing and culture, it is therefore necessary to establish some criteria to establish differences between special and craft beers.

This section analyzes the main criteria for classifying beers as special or craft beers ( Figure 2 ).

Main criteria to classify craft and special beers.

The first element taken into account is the production output of beer per year ( criterion 1 ). Craft beer are characterized by small production output and their “small,” “independent,” and “traditional” character. These characteristics are compatible with others which have been traditionally used to classify beer styles and now they are assuming new importance and making possible to enrich traditional beer brewing: we refer to type of fermentation and yeast strain selection ( criterion 2 ). Here, we will look at non- Saccharomyces brewing yeasts which require special attention [ 40 , 41 ]. While malted barley remains the main source of sugars for fermentation in the production of beer, the ingredients can be changed based on the region and preference of the consumer. Innovative ingredients in wort production can be used as a valuable source of variation in craft beer production ( criterion 3 ) The two last criteria are relatively recent and novel and are related with the development of special beers in the perspective on health and nutrition ( criterion 4 ) and with the use of emerging technologies in brewing ( criterion 5 ).

5.1 Production output of beer per year (scope of craft beer)

The annual beer production allows distinguishing between larger breweries mass-producing beer (annual production capacity of up to 6 million barrels) and craft beers or “small” scale breweries (less than 6 million barrels; where 1 BBL = 339 12 oz bottles of beer or 235 half-liter bottles of beer) [ 26 , 42 ].

Minimum production quantity: Nanobreweries .

The place of sale of beer: production is sold outside (Microbreweries) or on the same floor of production ( Brewpub ).

Brewing companies that outsource their production to other already established breweries ( Contract Brewing Company ).

Over 50% or more of their volume production focuses on all-malt beers and/or their malt flagship ( Regional Craft Brewery ).

The American craft brewing industry assumes that in addition to low volume production, further requirements are expected by the craft beers [ 36 ]. They are independent in that and not more than 25% of the business is owned by another member of the alcohol industry who is not a craft brewer. Traditional ingredients (water, malt, hops, yeast) must also be used in the brewing process although innovation in terms of reinterpreting historic beer styles or developing new styles is a hallmark of the industry.

5.2 Selection of the yeast strain and type of fermentation

The main brewing classification criterion particularly relies on the selection of the yeast strain and type of fermentation [ 35 , 41 ]. Two types of brewing yeast were originally classified based on their flocculation behavior during fermentation.

Beers are classified into two large groups according to the yeast strain and type of fermentation: Ale beers and Lager beers. Ale yeasts or top-fermenting yeasts , which are Saccharomyces cerevisiae strains, rise up to the surface of the vessel with the escaping carbon dioxide gas bubbles and become entangled in the fermentation head, facilitating their collection by skimming.

Ale yeast fermentation temperature ranges between 15 and 20°C. Lager yeast or bottom-fermenting yeast does not rise and becomes entrapped in the foam but settles out at the end of the fermentation. Lager worts often ferment at lower temperatures (8–14°C) than ale yeasts and are therefore much slower.

Ale beers represent only a small percentage of the total beer consumption. They are very common in Britain, Germany, Canada’s eastern provinces, the United States and, last but not least, Belgium. Until the sixteenth century, ale was the main type of beer in Europe [ 43 ].

Standard/ordinary bitter (Britain), English pale ale (Britain), Mild (Britain), Brown Porter (Britain), Robust Porter (Britain), Dry stout (Ireland), Sweet stout (Britain), Kölsch (Germany, Cologne), Lambic (Belgium), Rauchbier (Germany) and Weizen/Weissbier (Germany) are some examples of ale beer types.

Lager beer is the dominant style in almost all countries and represents more than 90% of the beer produced worldwide [ 43 ].

Some principal Lager beer types are: German Pilsner (Pils) (Germany), Bohemian Pilsener (Czech Republic), Classic American Pilsner (United States), Vienna Lager (Austria), Oktoberfest/Märzen (Germany), Dark American Lager (United States), Munich Dunkel (Germany), Schwarzbier (Black Beer) (Germany), Maibock/Helles Bock (Germany), Traditional Bock (Germany), Doppelbock (Germany), Eisbock (Germany).

In all beers cited, the flavor-active compounds such as acids, alcohols, aldehydes, ketones and esters are produced by yeast during fermentation. Although there are many strains of brewing yeast ( Saccharomyces cerevisiae ) for beer production, the choice of suitable yeasts to produce desirable tastes and flavors in beer is very important and significant.

5.2.1 Use of non- Saccharomyces

Several non- Saccharomyces yeasts can be used successfully in the making of craft beers with interesting possibilities. Yeasts such as Lachancea thermotolerans , Torulaspora delbrueckii , Hanseniaspora vineae and Schizosaccharomyces pombe can help to modulate acidity, aroma, mouthfeel or even color [ 41 , 44 ]. As the final alcoholic degree in beers is lower than in wines, and normally ranging between 4 and 8% vol, the use of medium fermentative power non- Saccharomyces species is possible because most of these yeasts are able to ferment reaching this ethanol level.

Lachancea thermotolerans is trending yeast in fermented beverages because of its ability to ferment until 4–9% vol producing high amounts of lactic acid from sugars. Therefore, it can be used to decrease pH of beverages [ 45 , 46 , 47 ]. Moreover, interesting effects in beer aroma can be reached by the production of fruity esters [ 48 ]. The use of L. thermotolerans has been also described in beer technology [ 49 , 50 ]. In the brewing of craft beers, L. thermotolerans can be used not only in the primary fermentation of the wort but also during the second fermentation in bottle to produce the suitable foam and CO 2 pressure. However, the most interesting application is in the production of sour beers because of the natural biological acidification during wort fermentation [ 46 ]. Moreover, even when the early use of L. thermotolerans has been proposed in winemaking in which the use of suitable species of these yeasts can produce pH reductions of 0.5 pH units [ 47 ] and the use in beer technology is even more effective due to the lower buffer effect in beer compared with wine. In our lab, we reached pH reductions of 1 pH unit [ 51 ]. The sensory effect of this acidity is described as a citric acidity without dairy hints because of the low production of acetoin and diacetyl [ 47 ]; moreover, the volatile acidity produced by L. thermotolerans is very low compared to volatile acidity produced by selected S. cerevisiae .

Torulaspora delbrueckii is another versatile yeast suitable for beer production. It has a medium fermentative power and improves the formation of fruity esters in addition to a low production of volatile acidity. These characteristics make it a good yeast for the initial fermentation of the must and the subsequent in bottle [ 50 ]. Also it is possible the use of this yeast sequentially or in mixed cultures with S. cerevisiae [ 52 ] or S. pombe [ 53 ]. It has been described as yeast able to decrease volatile acidity during fermentation. The ability to ferment sugars easily reaching 7–9% vol makes it interesting also for secondary bottle fermentation [ 52 ]. The production of 2-phenylethyl acetate, a floral ester with positive floral aroma, is increased during fermentation with T. delbrueckii ; moreover, high amounts of 3-ethoxy propanol are formed by this species [ 52 ]. The release of polysaccharides is also improved by the fermentation with T. delbrueckii affecting mouthfeel and structure [ 54 ].

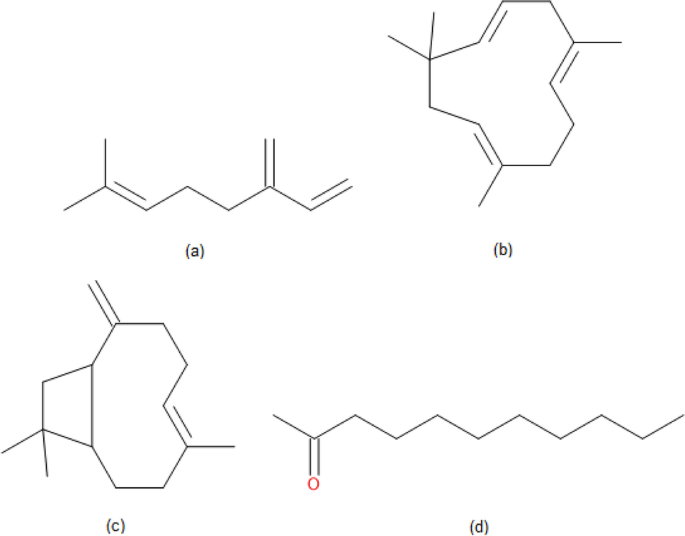

Hanseniaspora vineae is an apiculate yeast able to produce fresh and complex fermentation, increasing fruity aroma and producing full bodied structure [ 55 ]. It is possible to find strains with fermentative power close to 9% vol, which facilitate its use not only for primary fermentation but also for bottle fermentation. Moreover, it is a persistent yeast that can be found until the end of the alcoholic fermentation in wines and therefore also in beers because of the lower alcoholic degree. During the fermentation with H. vineae , an increase in the concentration of acetyl esters, benzenoids, and sesquiterpenes [ 56 , 57 ], and a decrease in the contents of alcohols and acids occurs. Intense either β-glucosidase or β-xylosidase activities has been described in some strains of H. vineae increasing the levels of hotrienol and 2,6-dimethyl-3,7-octadien-2,6-diol during fermentation [ 58 ]. It is especially noticeable the production of 2-phenylethyl acetate by H. vineae [ 55 ], compared with other Hanseniaspora / Kloeckera species.

Schizosaccharomyces pombe is a fission yeast able to produce maloalcoholic fermentation, and some strains can reach 13–15% vol of ethanol during fermentation [ 59 , 60 ]. The peculiar metabolism of S. pombe produces an intense degradation of malic acid together with a significant release of pyruvate in the fermentative media [ 60 ]. S. pombe is especially resistant to some common preservatives such as sulfur dioxide, actidione, benzoic acid, and dimethyl dicarbonate [ 59 , 61 ]. The main drawback of this yeast is the high production of volatile acidity. Concerning its structure this species has a peculiar and dense 2-layer cell wall. The autolysis produces the release of high amount of polysaccharides during maturation improving the mouth feel of beers [ 62 ]. This property can be especially interesting to produce full-bodied and soft bottle-aged beers. Moreover, we have observed intense bottle fermentation with good foam properties. The aromatic profile in beers is fruity and fresh when this is yeast is used specially in bottle fermentation.

5.3 Innovative ingredients

Raw material in wort production and parameters in production lead to produce an unlimited number of beer types. It might be argued that beer is a horizontally differentiated product . [ 35 ]. In fact, beers are quite similar in most respects but small differences in their composition can greatly affect both appearance and flavor [ 63 ].

We are going to examine each one of the raw materials separately.

5.3.1 Water

Water is quantitatively the main ingredient of beers; it forms more than 90% and often even more than 94% of the final product. The chemical composition of water has a determinant effect on beer properties and contributes significantly to the final beer flavor. The balance of minerals in brewing water will affect the flavor character and flavor perception of malt, hops, and by-products of fermentation. It may also influence the performance of yeast, which in turn influences the flavor, aroma, and mouthfeel of beer.

Chemical composition of water of the localities where famous beer styles were originated are very different in approximate ionic concentrations (in ppm). The chemical composition of water of Pilzen, Munich, Dortmund or Vienna is typical between Lager examples. Burton-on-Trent, Dublin or Edinburgh are typical between ale examples.

Malted barley is the main source for fermentable sugars used by yeasts in the traditional brewing of beers [ 64 ].

Depending on the conditions (time and temperature), pale or amber-colored or even dark malts are obtained; the color being due to caramelization of sugars and to Maillard-type reactions [ 65 ]. The variety of barely and the malting process influences the type and quality of beer [ 66 ]. To elaborate craft beer, the right malt is a key factor because craft beers include high proportion of adjuncts and enzymatic activity of malt has to ensure adequate hydrolysis of all the starch present in the wort.

5.3.3 Adjuncts

Malted barley is the main source for fermentable sugars used by yeasts in the traditional brewing, Other grains, malted or not, have been included to provide fermentable carbohydrates to the wort in addition to those from malt [ 63 ]. In former times, most cereals were used for malting, emmer, oats, spelt wheat, bread wheat were widely used and, in Estonia, rye was used up until the nineteenth century [ 67 ]. Outside Europe, millet, rice, maize and tuber plants have been, and are still, commonly used.

Bogdan and Kordialik-Bogacka [ 64 ] estimate that 85–90% of beer worldwide is now produced with adjuncts. Traditionally they had been used because they lead to reduce the cost of raw materials. When adjuncts are selected as unmalted grains, they present the added advantage of improved sustainability, by reducing reliance on the malting process [ 68 ] and its associated cost.

Craft brewing is increasing the use of adjuncts [ 68 ] because they lead to create a unique beer flavor/aroma [ 69 ]. Figure 3 shows the influence of different concentrations of roasted malt addition on sensory properties of beer.

Effect of roasted barley addition on beer sensory properties.

Appropriately chosen adjuncts can contribute to light or dark colors, improved colloidal or foam stability and prolongation beer shelf-life [ 64 ]. The flavor profile can also be changed by altering the sugar and amino acid spectra in wort.

Hops ( Humulus lupulus L.) are almost exclusively consumed by the brewing industry. Although hops are only a minority ingredient, they have significant impact on the sensory properties of beer [ 65 ]. It contributes not only to bitter flavor but also with the particular character of the selected hop variety [ 66 ].

This is mainly due to its particular chemical composition in: the hops resins, the hop oil and hop polyphenols [ 70 ].

In the closing years of the twentieth century, the hop became an icon of the “craft beer revolution” that swept across the United States. The “hopped up” vats created more flavorful and aromatic beers, making them more akin to European specialty varieties than anything seen in United States markets since before prohibition. The hops also became an effective marketing tool [ 39 ] from a nutritional and health point of view. It had recently come to light the effect antiviral and anti-HIV of xanthohumol, a phenylated flavonoid isolated from hops [ 66 ].

5.4 Perspective on health and nutrition

This section also includes a part on special or craft beers, which meet the new consumer requirements related with health and nutrition. In this context, it should include categories such as [ 66 ] light or low-calorie beers, low alcohol or non-alcohol beers, gluten free beers and functional beers.

5.4.1 Light beers

Light beer is a relatively new product on the market. Light beers contain at least one-third less calories than conventional beers [ 71 ]. However, these products are not widely accepted in Europe compared to North America and Australasia because of their lack of fullness in the taste and low bitterness compared with conventional beer. Enhanced hop character and addition of a low level of priming syrup have been proposed to the production of a low-calorie beer with a well-balanced and full beer flavor [ 38 ].

From a nutritional point of view [ 71 ], light beer contains less carbohydrate than regular beer, low alcohol beer or non-alcoholic beer. Surprisingly, light beer presents more calorie supply than such beers. This may be explained considering that light beer has a significant amount of alcohol (3%) providing a high calorie value.

5.4.2 Low alcohol beers

Low-alcohol beer is a beer with very low- or no-alcohol content. The alcohol by volume (ABV) limits depends on laws in different countries. In recent years, there has been an increased market share for low alcohol beers . This is mainly due to health and safety reasons and increasingly strict social regulations [ 72 ]. The alcohol-free beers also claim beneficial effects of healthy beer components with a simultaneous effect of the lower energy intake and complete absence of negative impacts of alcohol consumption.

According to Blanco et al. [ 73 ], the dealcoholization processes that are commonly used to reduce the alcohol content in beer have negative consequences to beer flavor. Several processes (physical and biological) have been developed for the production of low-alcohol or alcohol-free beer [ 74 ]. The physical processes include thermal and membrane processes such as thin-layer evaporation; falling film vacuum evaporation; continuous vacuum rectification; reverse osmosis; and dialysis. The biological processes include cold contact process (CCP); arrested fermentation; and use of special yeasts ( S. ludwigii ).

Overall, the taste defects in alcohol-free beer are mainly attributed to loss of aromatic esters, insufficient aldehydes, reduction or loss of different alcohols, and an indeterminate change in any of its compounds during the dealcoholization process or as a consequence of incomplete fermentation [ 73 ].

5.4.3 Gluten free

The market segment for gluten free (GF) products continues to grow rapidly and gluten free beers are a niche market with increasing demand [ 75 , 76 ].

Beer is considered unsuitable for people suffering from gluten intolerance, but with some modification and removal of proteins which occur during traditional beer processing. The majority of the precipitated protein remains in the spent grain after the lautering process and only a small proportion of gluten passes from malt to sweet wort. A study conducted by [ 77 ], in twenty-eight commercial beers, found that 10 of the tested beers contained less than 20 ppm gluten.

There are different alternatives for the reduction of gluten levels below the legislative gluten-free threshold (≤20 ppm) (EC No. 41/2009, 2009), on a daily basis, including precipitation and enzymatic hydrolysis. Deglutinization treatments by enzymatic process were proposed by Fanari et al. [ 78 ].

Furthermore, gluten free beers can be produced using gluten free cereals and pseudocereals . Currently only sorghum, rice, maize, millet, and buckwheat appear to be successful GF beer ingredients, while others have only shown adjunct possibilities. Among cereals, Teff is gaining a lot of popularity in GF beer production. Teff grain nutrients are promising and it is also an excellent GF alternative for people with celiac disease and other gluten allergy. Though the α- and β-amylase activities of teff malt are lower than that of barley, it has sufficient level of enzyme activities to be used as a raw material for malting [ 79 ] and GF beer production. Mayer et al. [ 80 ] has also prepared a GF beer from all-rice malt with sufficient endogenous enzyme activity for degradation of the rice components.

A third approach is the production of yeast fermented beverages based on fermentable sugars/syrups [ 75 ]. The search for new gluten-free brewing materials is still in its infancy and researchers in this field of study are continuously researching on the malting, mashing, fermentation conditions [ 78 ].

5.4.4 Functional beer

There is also scope for positioning low-calorie beers as a source of good carbohydrates, such as the soluble fiber and prebiotics derived from the β-linked glucans and arabinoxylans in the cereal walls [ 81 ]. Because these carbohydrates are neither metabolized by the brewing yeast nor they do not contribute toward calorie count but exert health benefits. Prebiotics are dominantly oligosaccharides that are nondigestible to human being but selectively stimulate growth and activity of beneficial bacteria (probiotics) in the human gastrointestinal tract.

Further, β-glucans could enhance stress tolerance of intestinal lactobacilli, which may have a positive impact on survival of probiotics. Nonetheless, high molecular weight b-linked glucan materials may have a negative impact on filtration efficiency and optimization of a filtration process will be required.

Probiotics are not limited to bacteria, and there is a well-known probiotic yeast strain of S. cerevisiae var. boulardii . A novel unfiltered and unpasteurized probiotic beer could be produced by fermenting wort with a probiotic strain of S. cerevisiae . A new category of functional beer could be the specialty beer of the future, given the rising consumer recognition and acceptance of probiotics [ 38 ].

5.5 Use of new technologies

Emerging technologies as high hydrostatic pressure (HHP) and ultra-high pressure homogenization (UHPH) open new possibilities in beer production. Both technologies are considered as cold techniques allowing the control of microorganisms in beverages [ 82 ]. Even when some temperature increasing is produced that can be quantified in 2–3°C/100 MPa in HHP [ 83 ] by compression adiabatic heat and until 100°C but just for 0.2 s in UHPH because of intense shear forces and impact [ 84 ]. The use of HHP is able to eliminate yeasts at pressures of 400 MPa-10 min but Gram-positive bacteria needs 600 MPa-10 min and spores remain unaffected even with these pressures [ 85 ]. Also it has the drawback of being a discontinuous technology. UHPH is now currently highly developed being a fast technology with a good industrial scale-up with equipment that are working at a flow of 10,000 l/h ( https://www.ypsicon.com/ ). Moreover, UHPH is a continuous technology and able to produce sterilization due to the extreme impacts and shear forces produced when the fluid pumped at 300 MPa cross the depressurization valve [ 84 ]. In beer production theoretically is possible to pump the beer at 300 MPa and release the pressure until 4 bar, later is possible to make a sterile iso-barometric bottling. The intense de-polymerization produced by UHPH can also disaggregate colloidal particles improving the beer structure and stability. Potentially it is possible to produce the mechanically lysis of the yeasts formed during fermentation increasing the amount of small size polysaccharides.

Other interesting technology that can be quite useful in beer production and sterilization is pulsed light (PL). This technology produces high energy light during a very short time (few μs) with a strong capacity to inactivate microorganisms and spores allowing sterilization [ 85 ]. The light is applied by flash lamps with a range spectra of 160–2600 nm with an intensity 105 folds the sunlight intensity at the seaside level. Power peak can reach 35 MW. PL technology is also a cold technology being a gentle process with sensory quality of beverages. This technique can be applied continuously during beer processing previously to packaging. It is also possible to use this technology to sterilize bottles or packages.

The use of these new technologies opens new possibilities in the processing and preservation of beer. UHPH and PL can be applied in a continuous way being efficient and easily implemented at industrial scale. Both sterilization technologies have a gentle repercussion in sensory quality of beverages.

6. Future trends

The development of new craft and special beers will be focused in the improvement on sensory properties and differentiation. Moreover, health care connotations are essential and should be supported by traditional processes but improved with both new biotechnologies and emerging processes.

- 1. Hayden B, Canuel N, Shanse J. What was brewing in the Natufian? An archaeological assessment of brewing technology in the Epipaleolithic. Journal of Archaeological Method and Theory. 2012; 20 (1):102-150. DOI: 10.1007/s10816-011-9127-y

- 2. Dineley M, Dineley G. Neolithic ale: Barley as a source of malt sugars for fermentation. In: Fairbairn AS, editor. Plants in Neolithic Britain and Beyond. Oxford: Oxbow; 2000. pp. 137-154

- 3. Cabras I, Higgins DM. Beer, brewing, and business history. Business History. 2016; 58 :609-624

- 4. McGovern P, Zhang J, Tang J, Zhang Z, Hall G, Moreau R, et al. Fermented beverages of pre- and proto-historic China. Proceedings of the National Academy of Sciences of the United States of America. 2004; 101 (51):17593-17599

- 5. Meussdoerffer FG. A comprehensive history of beer brewing. In: Esslinger HM, editor. Handbook of Brewing. Weinheim: Wiley-VCH Verlag GmbH & Co.; 2009. pp. 1-42

- 6. Bai J, Huang J, Rozelle S, Boswell M. Beer battles in China: The struggle over the World’s largest beer market. In: Swinnen JFM, editor. The Economics of Beer. Oxford: Oxford University Press; 2011. pp. 267-286

- 7. Jiajing W, Li L, Terry B, Linjie Y, Yuanqing L, Fulai X. Revealing a 5,000-y-old beer recipe in China. Proceedings of the National Academy of Sciences of the United States of America. 2016; 113 (23):6444-6448

- 8. Hardwick WA. History and antecedents of brewing. In: Hardwick WA, editor. Handbook of Brewing. New York: Marcel Dekker; 1994. pp. 37-52

- 9. Cortacero-Ramirez S, De Castro MHB, Segura-Carretero A, Cruces-Blanco C, Fernandez-Gutierrez A. Analysis of beer components by capillary electrophoretic methods. Trends in Analytical Chemistry. 2003; 22 (7):440-455

- 10. Michel C. L’alimentation au Proche-Orient ancien: Les sources et leur exploitation. Dialogues d'Histoire Ancienne. 2012; 7 :17-45

- 11. Maksoud SA, Hadidi MN, Amer WN. Beer from the early dynasties (3500-3400 cal. B.C.) of Upper Egypt, detected by archaeochemical methods. Vegetation History and Archaeobotany. 1994; 3 (4):219-224

- 12. Nelson M. The barbarian's Beverage: A History of Beer in Ancient Europe. London/New York: Routledge; 2005. DOI: 10.4324/9780203309124. Available from: https://scholar.uwindsor.ca/llcpub/26

- 13. Poelmans E, Swinnen JFM. From monasteries to multinationals (and back): A historical review of the beer economy. The Journal of Wine Economics. 2011; 6 (2):196-216

- 14. Moore J. Pre-Hispanic beer in coastal Peru: Technology and social context of prehistoric production. American Anthropologist. 1989; 91 (3):682-695

- 15. Burger RL, Van Der Merwe NJ. Maize and the origin of Highland Chavín civilization: An isotopic perspective. American Anthropologist. 1990; 92 (1):85-95

- 16. Hastorf CA, Johannessen S. Pre-Hispanic political change and the role of maize in the Central Andes of Peru. American Anthropologist. 1993; 95 (1):115-138

- 17. Liua L, Wanga J, Rosenbergb D, Zhaoc H, Lengyeld G, Nadel D. Fermented beverage and food storage in 13,000 y-old stone mortars at Raqefet cave, Israel: Investigating Natufian ritual feasting. Journal of Archaeological Science: Reports. 2018; 21 :783-793

- 18. Perruchinia E, Glatza C, Haldb MM, Casanac J, Toneyd JL. Revealing invisible brews: A new approach to the chemical identification of ancient beer. Journal of Archaeological Science. 2018; 100 :176-190

- 19. Howard PH. Too big to ale? Globalization and consolidation in the beer industry. In: Patterson MW, Pullen NH, editors. The Geography of Beer: Regions, Environment, and Society. Dordrecht, The Netherlands: Springer; 2014; pp. 155-165

- 20. Sewell SL. The spatial diffusion of beer from its Sumerian origins to today. In: Patterson M, Hoalst-Pullen N, editors. The Geography of Beer: Regions, Environment, and Society. Dordrecht: Springer; 2014. pp. 23-29. https://doi.org/10.1007/978-94-007-7787-3_3

- 21. Elzinga K, Tremblay C, Tremblay V. Craft beer in the United States: History, numbers, and geography. The Journal of Wine Economics. Dordrecht, Springer; 2015; 10 (3):242-274. DOI: 10.1017/jwe.2015.22

- 22. Garavaglia C. Birth and Diffusion of Craft Breweries in Italy. In: Garavaglia C, Swinnen J, editors. Economic Perspectives on Craft Beer: A Revolution in the Global Beer Industry. London: Palgrave Macmillan; 2017

- 23. van Dijk M, Kroezen J, Slob B. From Pilsner Desert to craft beer oasis: The rise of craft brewing in the Netherlands. In: Economic Perspectives on Craft Beer. Cham, Switzerland: Palgrave McMillan; 2017. pp. 259-293. DOI: 10.1007/978-3-319-58235-1_10. ISBN: 978-3-319-58235-1

- 24. Sammartino A. Craft brewing in Australia, 1979-2015. In: Garavaglia C, Swinnen J, editors. Economic Perspectives on Craft Beer: A Revolution in the Global Beer Industry. London/New York: Palgrave Macmillan; 2018. pp. 397-423

- 25. Depenbusch L, Ehrich M, Pfizenmaier U. Craft Beer in Germany–New Entries in a Challenging Beer Market. In: Garavaglia C, Swinnen J, editors. Economic Perspectives on Craft Beer: A Revolution in the Global Beer Industry. London, New York: Palgrave Macmillan; 2018

- 26. Garavaglia C, Swinnen J. The craft beer revolution: An international perspective. Choices. 2017; 32 (3):1-8. Available from: http://www.choicesmagazine.org/choices-magazine/theme-articles/global-craft-beer-renaissance/the-craft-beer-revolution-an-international-perspective

- 27. Brewers Association. 2019. Retrieved from: https://www.brewersassociation.org/statistics/ [Accessed: April 1, 2019]

- 28. Bamforth C, Cabras I. Interesting times: Changes for brewing. In: Cabras I, Higgins D, Preece D, editors. Brewing, Beer and Pubs: A Global Perspective. London: Palgrave Macmillan; 2016. pp. 13-33

- 29. The Brewers of Europe. Beer Statistics—2018 and Previous Years. 2018. Retrieved from: https://brewersofeurope.org/site/index.php [Accessed: April 1, 2019]

- 30. Australia and New Zealand Banking Group Limited (ANZ). New Zealand craft beer industry insights: ANZ industry reports. 2017. Available from: https://comms.anz.co.nz/businsights/article/report.html?industry=Craft%20Beer [accessed: April 1, 2018]

- 31. Tripes S, Dvořák J. Strategic forces in the Czech brewing industry from 1990-2015. Acta Oeconomica Pragensia. 2017; 3 :3-38

- 32. Rogerson CM, Collins KGE. Developing beer tourism in South Africa: International perspectives. African Journal of Hospitality, Tourism and Leisure. 2015; 4 (1):1-15

- 33. Beer Canada. 2015 Industry Trends . 2016. Available from: http://www.beercanada.com/sites/default/files/2015_industry_trends_final.pdf

- 34. Gómez-Corona C, Lelievre-Desmas M, Buendía HBE, Chollet S, Valentin D. Craft beer representation amongst men in two different cultures. Food Quality and Preference. 2016; 53 :19-28

- 35. Clemons EK, Gao GG, Hitt LM. When online reviews meet hyperdifferentiation: A study of the craft beer industry. Journal of Management Information Systems. 2006; 23 (2):149-171

- 36. Reid N, McLaughlin RB, Moore MS. From yellow fizz to big biz: American craft beer comes of age. Focus on Geography. 2014; 57 (3):114-125

- 37. Smith S, Farrish J, McCarroll M, Huseman E. Examining the craft brew industry: Identifying research needs. International Journal of Hospitality Beverage Management. 2017; 1 (1):3

- 38. Yeo HQ , Liu SQ. An overview of selected specialty beers: Developments, challenges and prospects. International Journal of Food Science & Technology. 2014; 49 (7):1607-1618

- 39. Kopp P. The global hop: An agricultural overview of the brewer’s gold. In: Patterson M, Hoalst-Pullen N, editors. The Geography of Beer. Dordrecht: Springer; 2014

- 40. Tataridis P, Kanelis A, Logotetis S, Nerancis E. Use of non- Saccharomyces Torulaspora delbrueckii yeast strains in winemaking and brewing. Zbornik Matice Srpske za Prirodne Nauke. 2013; 124 :415-426

- 41. Callejo MJ, González C, Morata A. Use of non- Saccharomyces yeasts in bottle fermentation of aged beers. In: Kanauchi M, editor. Brewing Technology. Rijeka, Croatia: IntechOpen; 2017. DOI: 10.5772/intechopen.68793. Available from: https://www.intechopen.com/books/brewing-technology/use-of-non-saccharomyces-yeasts-in-bottle-fermentation-of-aged-beers

- 42. Kleban J, Nickerson I. To brew, or not to brew-that is the question: An analysis of competitive forces in the craft brew industry. Journal of the International Academy for Case Studies. 2012; 18 (3):59

- 43. Pavsler A, Buiatti S. Non-lager beer. In: Beer in Health and Disease Prevention. London, United Kingdom: Academic Press; 2009. pp. 17-30

- 44. Budroni M, Zara G, Ciani M, Comitini F. Saccharomyces and non- Saccharomyces starter yeasts. In: Kanauchi M, editor. Brewing Technology. Rijeka, Croatia: IntechOpen; 2017. DOI: 10.5772/intechopen.68792. Available from: https://www.intechopen.com/books/brewing-technology/saccharomyces-and-non-saccharomyces-starter-yeasts

- 45. Gobbi M, Comitini F, Domizio P, Romani C, Lencioni L, Mannazzu I, et al. Lachancea thermotolerans and Saccharomyces cerevisiae in simultaneous and sequential co-fermentation: A strategy to enhance acidity and improve the overall quality of wine. Food Microbiology. 2013; 33 :271-281. DOI: 10.1016/j.fm.2012.10.004

- 46. Morata A, Loira I, Tesfaye W, Bañuelos MA, González C, Suárez Lepe JA. Lachancea thermotoleran s applications in wine technology. Fermentation. 2018; 4 :53. DOI: 10.3390/fermentation4030053

- 47. Morata A, Bañuelos MA, Vaquero C, Loira I, Cuerda R, Palomero F, et al. Lachancea thermotolerans as a tool to improve pH in red wines from warm regions. European Food Research and Technology. 2019; 245 :885-894. DOI: 10.1007/s00217-019-03229-9

- 48. Escott C, Morata A, Ricardo-da-Silva JM, Callejo MJ, González MC, Suarez-Lepe JA. Effect of Lachancea thermotolerans on the formation of polymeric pigments during sequential fermentation with Schizosaccharomyces pombe and Saccharomyces cerevisiae . Molecules. 2018; 23 :2353. DOI: 10.3390/molecules23092353

- 49. Domizio P, House JF, Joseph CML, Bisson LF, Bamforth CW. Lachancea thermotolerans as an alternative yeast for the production of beer. Journal of the Institute of Brewing. 2016; 122 :599-604. DOI: 10.1002/jib.362

- 50. Callejo MJ, García Navas JJ, Alba R, Escott C, Loira I, González MC, et al. Wort fermentation and beer conditioning with selected non- Saccharomyces yeasts in craft beers. European Food Research and Technology. 2019; 245 :1229-1238. DOI: 10.1007/s00217-019-03244-w

- 51. Vanooteghem M. Impact of non- Saccharomyces fermentations on the flavour profile of craft beer [MS thesis]. Madrid, Spain: Technical University of Madrid; 2019

- 52. Loira I, Vejarano R, Bañuelos MA, Morata A, Tesfaye W, Uthurry C, et al. Influence of sequential fermentation with Torulaspora delbrueckii and Saccharomyces cerevisiae on wine quality. LWT - Food Science and Technology. 2014; 59 :915-922. DOI: 10.1016/j.lwt.2014.06.019

- 53. Loira I, Morata A, Comuzzo P, Callejo MJ, González C, Calderón F, et al. Use of Schizosaccharomyces pombe and Torulaspora delbrueckii strains in mixed and sequential fermentations to improve red wine sensory quality. Food Research International. 2015; 76 :325-333. DOI: 10.1016/j.foodres.2015.06.030

- 54. Comitini F, Gobbi M, Domizio P, Romani C, Lencioni L, Mannazzu I, et al. Selected non- Saccharomyces wine yeasts in controlled multistarter fermentations with Saccharomyces cerevisiae . Food Microbiology. 2011; 28 :873-882. DOI: 10.1016/j.fm.2010.12.001

- 55. Martin V, Valera MJ, Medina K, Boido E, Carrau F. Oenological impact of the Hanseniaspora/Kloeckera yeast genus on wines—A review. Fermentation. 2018; 4 :76. DOI: 10.3390/fermentation4030076

- 56. Martin V, Giorello F, Fariña L, Minteguiaga M, Salzman V, Boido E, et al. De novo synthesis of benzenoid compounds by the yeast Hanseniaspora vineae increases the flavor diversity of wines. Journal of Agricultural and Food Chemistry. 2016; 64 :4574-4583

- 57. Martin V, Boido E, Giorello F, Mas A, Dellacassa E, Carrau F. Effect of yeast assimilable nitrogen on the synthesis of phenolic aroma compounds by Hanseniaspora vineae strains. Yeast. 2016; 33 :323-328

- 58. López S, Mateo JJ, Maicas S. Characterisation of Hanseniaspora isolates with potential aroma enhancing properties in Muscat wines. South African Journal of Enology and Viticulture. 2014; 35 :292-303

- 59. Suárez-Lepe JA, Palomero F, Benito S, Calderón F, Morata A. Oenological versatility of Schizosaccharomyces spp. European Food Research and Technology. 2012; 235 :375-383

- 60. Loira I, Morata A, Palomero F, González C, Suárez-Lepe JA. Schizosaccharomyces pombe : A promising biotechnology for modulating wine composition. Fermentation. 2018; 4 :70. DOI: 10.3390/fermentation4030070

- 61. Escott C, Loira I, Morata A, Bañuelos MA, Suárez-Lepe JA. Wine spoilage yeasts: Control strategy. In: Morata A, Loira I, editors. Yeast-Industrial Applications. London, UK: InTech; 2017. pp. 89-116

- 62. Palomero F, Morata A, Benito S, Calderón F, Suárez-Lepe JA. New genera of yeasts for over-lees aging of red wine. Food Chemistry. 2009; 112 :432-441

- 63. Buiatti S. Beer composition: An overview. In: Beer in Health and Disease Prevention. London, United Kingdom: Academic Press; 2009. pp. 213-225

- 64. Bogdan P, Kordialik-Bogacka E. Alternatives to malt in brewing. Trends in Food Science & Technology. 2017; 65 :1-9

- 65. De Keukeleire D. Fundamentals of beer and hop chemistry. Quimica Nova. 2000; 23 (1):108-112

- 66. Sohrabvandi S, Mortazavian AM, Rezaei K. Health-related aspects of beer: A review. International Journal of Food Properties. 2012; 15 (2):350-373

- 67. Behre KE. The history of beer additives in Europe—A review. Vegetation History and Archaeobotany. 1999; 8 (1-2):35-48

- 68. Kok YJ, Ye L, Muller J, Ow DSW, Bi X. Brewing with malted barley or raw barley: What makes the difference in the processes? Applied Microbiology and Biotechnology. 2019; 103 (3):1059-1067

- 69. Schnitzenbaumer B, Arendt EK. Brewing with up to 40% unmalted oats ( Avena sativa ) and sorghum ( Sorghum bicolor ): A review. Journal of the Institute of Brewing. 2014; 120 (4):315-330

- 70. Steenackers B, De Cooman L, De Vos D. Chemical transformations of characteristic hop secondary metabolites in relation to beer properties and the brewing process: A review. Food Chemistry. 2015; 172 :742-756

- 71. Blanco CA, Caballero I, Barrios R, Rojas A. Innovations in the brewing industry: Light beer. International Journal of Food Sciences and Nutrition. 2014; 65 (6):655-660

- 72. Brányik T, Silva DP, Baszczyňski M, Lehnert R, e Silva JBA. A review of methods of low alcohol and alcohol-free beer production. Journal of Food Engineering. 2012; 108 (4):493-506

- 73. Blanco CA, Andrés-Iglesias C, Montero O. Low-alcohol beers: Flavor compounds, defects, and improvement strategies. Critical Reviews in Food Science and Nutrition. 2016; 56 (8):1379-1388

- 74. Montanari L, Marconi O, Mayer H, Fantozzi P. Production of alcohol-free beer. In: Beer in Health and Disease Prevention. London, United Kingdom: Academic Press; 2009. pp. 61-75

- 75. Hager AS, Taylor JP, Waters DM, Arendt EK. Gluten free beer—A review. Trends in Food Science & Technology. 2014; 36 (1):44-54

- 76. Watson HG, Vanderputten D, Van Landschoot A, Decloedt AI. Applicability of different brewhouse technologies and gluten-minimization treatments for the production of gluten-free (barley) malt beers: Pilot-to industrial-scale. Journal of Food Engineering. 2019; 245 :33-42

- 77. Guerdrum LJ, Bamforth CW. Prolamin levels through brewing and the impact of prolyl endoproteinase. Journal of the American Society of Brewing Chemists. 2012; 70 :35-38

- 78. Fanari M, Forteschi M, Sanna M, Zinellu M, Porcu MC, Pretti L. Comparison of enzymatic and precipitation treatments for gluten-free craft beers production. Innovative Food Science & Emerging Technologies. 2018; 49 :76-81

- 79. Gebremariam MM, Zarnkow M, Becker T. Teff ( Eragrostis tef ) as a raw material for malting, brewing and manufacturing of gluten-free foods and beverages: A review. Journal of Food Science and Technology. 2014; 51 (11):2881-2895

- 80. Mayer H, Ceccaroni D, Marconi O, Sileoni V, Perretti G, Fantozzi P. Development of an all rice malt beer: A gluten free alternative. LWT- Food Science and Technology. 2016; 67 :67-73

- 81. Bamforth CW. Beer, carbohydrates and diet. Journal of the Institute of Brewing. 2005; 111 (3):259-264

- 82. Morata A, Loira I, Vejarano R, González C, Callejo MJ, Suárez-Lepe JA. Emerging preservation technologies in grapes for winemaking. Trends in Food Science & Technology. 2017; 67 :36-43. DOI: 10.1016/j.tifs.2017.06.014

- 83. Bañuelos MA, Loira I, Escott C, Del Fresno JM, Morata A, Sanz PD, et al. Grape processing by high hydrostatic pressure: Effect on use of non- Saccharomyces in must fermentation. Food and Bioprocess Technology. 2016; 9 :1769-1778. DOI: 10.1007/s11947-016-1760-8

- 84. Loira I, Morata A, Bañuelos MA, Puig-Pujol A, Guamis B, González C, et al. Use of ultra-high pressure homogenization processing in winemaking: Control of microbial populations in grape musts and effects in sensory quality. Innovative Food Science and Emerging Technologies. 2018; 50 :50-56

- 85. Morata A, Loira I, Vejarano R, Bañuelos MA, Sanz PD, Otero L, et al. Grape processing by high hydrostatic pressure: Effect on microbial populations, phenol extraction and wine quality. Food and Bioprocess Technology. 2015; 8 :277-286. DOI: 10.1007/s11947-014-1405-8

© 2019 The Author(s). Licensee IntechOpen. This chapter is distributed under the terms of the Creative Commons Attribution 3.0 License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Continue reading from the same book

Published: 05 February 2020

By Octavio García-Depraect, Daryl Rafael Osuna-Laveag...

1156 downloads

By Yonglan Tian, Huayong Zhang and Edmond Sanganyado

995 downloads

By Pascal Drouin, Lucas J. Mari and Renato J. Schmidt

1505 downloads

More than just a beer—the potential applications of by-products from beer manufacturing in polymer technology

- Open access

- Published: 24 September 2021

- Volume 5 , pages 765–783, ( 2022 )

Cite this article

You have full access to this open access article

- Aleksander Hejna ORCID: orcid.org/0000-0001-9125-6164 1

7066 Accesses

13 Citations

1 Altmetric

Explore all metrics

Beer is the most popular alcoholic beverage in the world, and its popularity is continuously growing. Currently, global beer production is estimated at around 2 billion hectoliters. Nevertheless, the increasing production capacity implicates the rising issue of generated by-products—brewers’ spent grain, spent hops, spent yeast, and wastewater. They are generated in massive amounts, so having in mind the current pro-ecological trends, it is crucial to look for their utilization methods. Among the possibilities, particular attention should be drawn to polymer technology. This sector can efficiently use different lignocellulosic materials, which could be applied as fillers for polymer composites or sources of particular chemical compounds. Moreover, due to their chemical composition, brewing industry by-products may be used as functional fillers and additives. They could be introduced to enhance the materials’ resistance to oxidation, microbes, or fungi. These issues should be considered especially important in the case of biodegradable polymers, whose popularity is growing over the last years. This paper summarizes the literature reports related to the composition and potential applications of the brewing industry by-products in polymer technology. Moreover, potential directions of research based on the possibilities offered by the brewing industry by-products are presented.

Similar content being viewed by others

Aldehydes as Wort Off-Flavours in Alcohol-Free Beers—Origin and Control

Microbial pullulan for food, biomedicine, cosmetic, and water treatment: a review

Lignocellulosic Agricultural Biomass as a Biodegradable and Eco-friendly Alternative for Polymer-Based Food Packaging

Avoid common mistakes on your manuscript.

1 Introduction

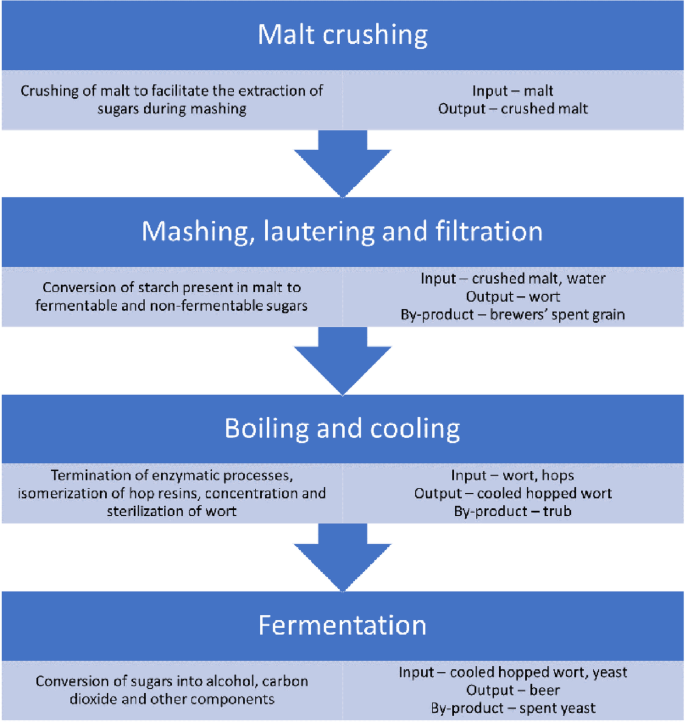

As a process aimed at beer production, brewing is known for thousands of years [ 1 ]. Depending on the times and mainly the development of humanity and science, the specifics of this process were changing [ 2 ]. Figure 1 presents the current general scheme of beer production. Generally, the brewing process consists of the following stages, starting from the malt: crushing of malt, mashing, lautering, filtration, boiling, and fermentation. At first, malt is crushed to break apart the kernel and facilitate the extraction of sugars during mashing [ 3 ].

The general scheme of beer production with an indication of generated by-products

Then, crushed malt is mixed with hot water in a mash tun creating the cereal mash. Naturally occurring enzymes present in the malt convert the starch extracted from the malt into simpler fermentable and non-fermentable sugars in the saccharification process [ 4 ]. To enhance the yield of mashing, in the end, the mas is often heated up to 76–78 °C, which is called mashout, and sprinkled with additional water during sparging [ 5 ]. Such processes are implemented to reduce mash viscosity, free up more starch, and extract additional sugars [ 6 ]. As a result, a sugar-rich liquid called wort is obtained after separation from the solid residue of mashing called the brewers’ spent grain (BSG) [ 7 ].

The wort is moved to the kettle, where it is boiled with hops (and sometimes other ingredients). The boiling process aims to terminate the enzymatic processes, precipitate proteins, concentrate and sterilize the wort, as well as extract compounds from hops to beer and isomerize hop resins to add bitterness to beer [ 8 ]. Moreover, boiling may induce caramelization and Maillard reactions in wort [ 9 ]. In the end, the hopped wort is cooled down and separated from the trub, which includes the hop residues and colloidal proteins coagulated during boiling [ 10 ].

Cooled and hopped wort is transferred to the fermentation tanks and pitched with yeast, converting the fermentable sugars into alcohol and carbon dioxide. Moreover, depending on the type of yeast, different reactions occur, which account for the beer’s final taste and aroma profile [ 11 ]. After complete fermentation, the beer is separated from the surplus yeast, called spent yeast, conditioned in the additional tank, and packed into bottles, casks, or cans [ 12 ].

2 Beer production statistics

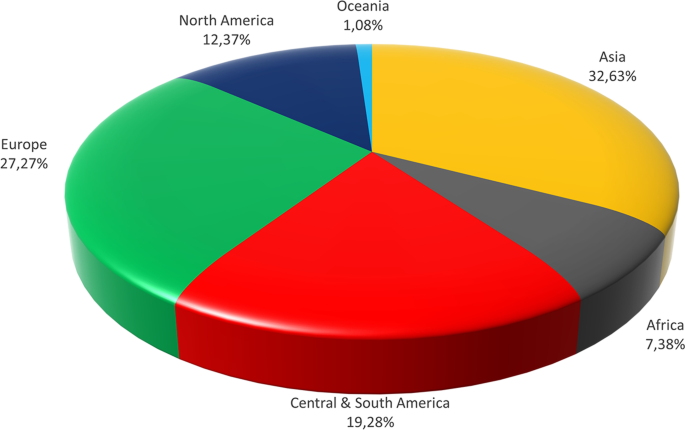

Beer is the most popular alcoholic beverage globally and the third most popular beverage after water and tea [ 13 ]. The global beer production size is relatively stable in the last decade and accounts for 1.91–1.97 billion hectoliters [ 13 ]. The leading producer is China, whose production in 2019 equaled 376.5 million hectoliters and accounted for ~ 20% of global production [ 14 ]. The Americas occupy the following positions—the United States, Brazil, and Mexico with 210.3, 144.8, and 124.2 million hectoliters, respectively [ 15 ]. Considering Europe, the size of production exceeds 420 million hectoliters annually [ 16 ]. The share of particular continents in the global beer production is presented in Fig. 2 . The biggest producer is Germany, the country with great brewing traditions. In 2019, Germans produced 91.6 million hectoliters of beer, mostly pilsener and wheat beer [ 17 ]. In Europe, Germany is followed by Poland and the UK, whose production is around 40 million hectoliters [ 18 ]. It is also essential to mention Russia as a critical producer with 77.4 million hectoliters produced in 2019 [ 19 ]. Russia is one of the few countries where beer is not the most popular alcoholic beverage, with a higher vodka share [ 20 ]. Presented data indicate that global beer production is distributed across all the regions of the world. Therefore, research activities related to the manufacturing, consumption, and health aspects and the utilization of by-products of beer production are essential because these aspects may affect an enormous number of people worldwide.

The share of particular continents in the global beer production

3 Beer production by-products

Conventionally, beer is produced from barley and, to a noticeably lesser extent, from wheat [ 21 ]. Such a production model is commonly applied in Europe. Moreover, in Germany, such issues are regulated by Germany’s Beer Purity Law, originating from the medieval Bayreisches Reinheitsgebot [ 22 ]. Nevertheless, in different regions of the world, other starch sources are also applied, such as maize in America [ 23 ], rice in Asia [ 24 ], or sorghum in Africa [ 25 ]. Considering hops and yeast, their use is associated with the desired beer style. The market offers an enormous range of hops and yeast varieties [ 26 , 27 ].

According to the brewing scheme presented in Fig. 1 , the main by-products of beer manufacturing are the brewers’ spent grain, trub removed after wort boiling, and spent yeast. The generation of brewing by-products is very similar globally, with possible differences in their composition, depending on the location. These materials are currently often unutilized and present hardly any market value. Generally, considering the current pro-environmental trends in scientific and industrial activities partially stimulated by the changing law regulations established worldwide, waste and by-products management are essential [ 28 ]. Except for the environmental motivations, the application of such materials in various production processes can generate added value for the resulting products (enhanced performance or new properties) or reduce their manufacturing costs [ 29 ].

One of the industry branches where by-products from beer manufacturing could be potentially applied in polymer technology. This sector of the industry is enormously dependent on petroleum price and availability [ 30 ]. It is commonly known that its resources are constantly shrinking, and it is essential to seek new raw materials, which could substitute petroleum, beneficially from renewable resources [ 31 ]. In the following sections, the literature reports on the applications of brewing by-products in polymer technology would be discussed.

3.1 Brewers’ spent grain

3.1.1 overview.

The main and the most abundant by-product generated by the brewing industry is brewers’ spent grain. It is generated in high amounts and accounts for over 85% of beer manufacturing by-products [ 32 ]. During the mashing process, around 69% of the initial malt mass is extracted and converted to sugars soluble in wort [ 33 ]. Considering that production of the one hectoliter of beer uses 20 kg of malt, around 6.2 kg of dry BSG is generated. Such values are typical for the most popular beer style worldwide—light lager [ 34 ]. Other beer styles, especially those characterized by higher original gravity, require higher malt loadings, even up to 45 kg for strong stouts or porters [ 35 ]. Keeping in mind the size of the global beer production, almost 12 million tonnes of brewers’ spent grain is generated worldwide. The biggest producer, China, accounts for over 2.3 million tonnes, followed by the USA with 1.3 million tonnes, while European production generates around 2.6 million tonnes of BSG [ 34 ].

3.1.2 Composition

One of the main drawbacks of BSG as a potential raw material for other processes is its high moisture content, exceeding 75% [ 36 ]. Together with the presence of polysaccharides, this factor makes the BSG a perishable material. Drying of brewers’ spent grain, which could be easily performed using conventional dryers, might noticeably enhance its attractiveness for other industry branches, including polymer technology [ 37 ]. Moreover, BSG is characterized by the relatively low activation energy values during drying, comparable to other food industry by-products such as carrots, beans, or general vegetable waste [ 38 ]. The drying of BSG requires less energy than, e.g., olive processing by-products, probably due to their high lipid content [ 38 ].

The brewers’ spent grain can be characterized by a similar composition to various lignocellulose materials except for the high moisture content. As presented in Table 1 , the total content of carbohydrates in BSG is around 50%, which is noticeably lower compared to other lignocellulose waste materials, e.g., barley straw (56%) [ 39 ], rye, or oat straw (66–68%) [ 40 ], sunflower or cotton stalks (72–73%) [ 40 ]. Such a phenomenon is attributed to the partial reduction of carbohydrate content during mashing when starch is removed [ 41 ].

Moreover, brewers’ spent grain contains from 10 to even 28% of lignin, depending on the reports [ 48 ] and a significant amount of proteins, which is attributed to their high content in barley grain [ 52 ]. The detailed composition of proteins in BSG may differ depending on the determination method, source of by-product, and applied malts, mostly crop species [ 33 ]. According to Robertson et al. [ 53 ], the glutamine is the primary amino acid of BSG (around 19–20% of total proteins), followed by a proline (~ 9%), asparagine, and leucine (both ~ 8%), arginine, phenylalanine, and valine (~ 7%). On the other hand, Waters et al. [ 54 ] reported that histidine is present in the highest amount exceeding 26% of total proteins, followed by glutamine (~ 16%), lysine (~ 14%), and leucine (~ 6%), while the content of other amino acids does not exceed 5%. Nevertheless, irrespectively of the detailed composition of amino acids, BSG should be considered as protein-rich material.

Brewers’ spent grain often contains noticeable amounts of phenolics, which may provide additional value for various applications due to their antioxidant and antimicrobial properties [ 55 ]. The main phenolic components of BSG are hydroxycinnamic acids (HCAs) and hydroxybenzoic acids (HBAs), particularly ferulic, p -coumaric, sinapic, syringic, and caffeic acids [ 56 , 57 , 58 ]. The first two compounds are present in the highest amounts, but the literature reports indicate that their contents depend strongly on the type of malts used for brewing [ 59 ]. McCarthy et al. [ 59 ] showed that the roasting of pale barley malt reduced the total HCAs content in BSG by 57%. Also, Moreira et al. [ 60 ] pointed to the reduction in total phenolic content due to increasing malt kilning temperature. For chocolate and black malts, kilned at temperatures exceeding 220 °C, the content of ferulic and p -coumaric acids was reduced by over 50%. The effect was significantly smaller for melanoidin and carared malts, which were subjected to a temperature in the range of 120–160 °C.

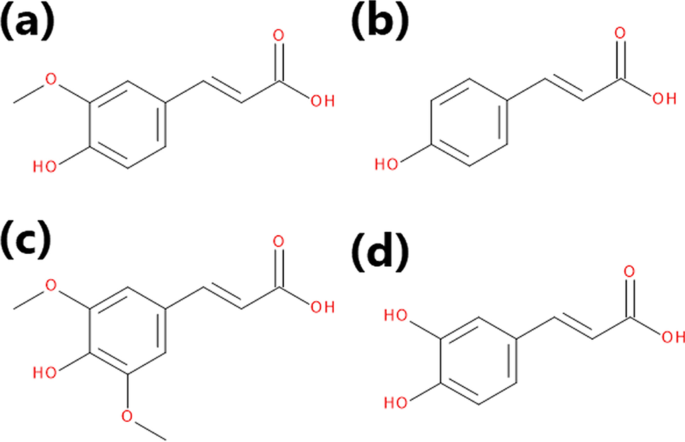

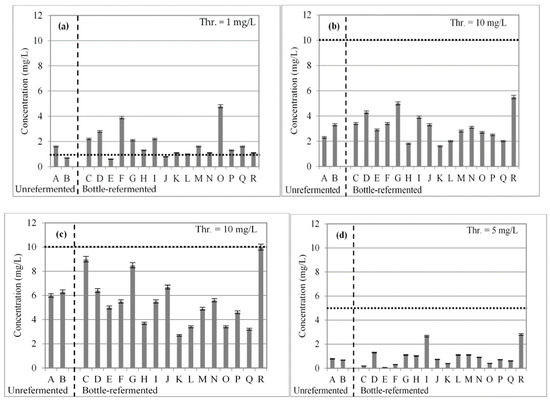

Generally, the structures of the major phenolic acids present in brewers’ spent grain are presented in Fig. 3 . Their detailed composition in particular BSG samples and other by-products, may noticeably differ depending on the method of their extraction, selection of solvents, and method of the quantitative analysis [ 35 ]. Nevertheless, despite the differences in reported contents of HCAs and other phenolics, they significantly enhance the antioxidant activity of BSG compared to other lignocellulose materials.

The structures of the major phenolics of BSG: a ferulic, b p -coumaric, c sinapic, and d caffeic acid

These compounds mentioned above present in BSG are considered strong antioxidants and may enhance the stability of polymeric materials [ 61 , 62 , 63 ]. Considering the antioxidant activity of BSG, it may contain noticeable amounts of melanoidins, mainly when it originated from the production of darker beers. Melanoidins are generated during Maillard reactions occurring between carbonyl groups of reducing sugars and amino groups of amino acids present in proteins [ 64 ]. As a result, the complex mixture of higher molecular weight oligomeric and polymeric compounds is obtained [ 65 ]. They are responsible for the browning reactions of various food products after applying temperature, e.g., during baking, frying, or cooking [ 66 ].

Moreover, the brewers’ spent grain contains multiple micro- and macroelements, mostly silicon, phosphorous, calcium, and magnesium [ 32 ]. Combining their content with the presence of vitamins, primarily B3, B4, and B5, the BSG is often investigated in food additives [ 48 , 67 ].

3.1.3 Current applications and potential in polymer technology

Animal feed.

Nowadays, the main application of brewers’ spent grain is low-value animal feed with relatively low market value. It is often sold to farmers, mainly in a wet state [ 68 ]. It is associated with the composition of this by-product, particularly protein content [ 45 ]. As a result, Belibasakis and Tsirgogianni [ 69 ] and Sawadogo et al. [ 70 ] reported the enhanced milk production for cows fed with BSG. Also, other works reported the beneficial impact on animal nutrition, including fish, pigs, and chickens [ 71 , 72 , 73 ]. In the case of lack of potential recipients of BSG for animal feed, this by-product may be deposited in the fields, where in moderate amounts, it can act as natural fertilizer [ 55 ].

Considering the nutrition, brewers’ spent grain was also investigated as a human food ingredient. Because of its composition and origin, it was introduced into bakery products as a flour substitute [ 74 ]. Ground BSG is characterized by a darker color than the lightest types of flour, so it could not be applied in white bread [ 75 ]. Nevertheless, BSG showed a very beneficial impact on the bread protein content due to its composition, increasing it by ~ 50%, when only 10% of traditional flour was replaced [ 76 ]. Combining the protein content with the lack of starch (which is removed during mashing—see Fig. 1 ), the caloric density of bread containing 10% of BSG may be even 7% lower compared to the conventional bread [ 77 ]. Except for the bakery products, brewers’ spent grain can be incorporated into other high-fiber foods [ 78 , 79 , 80 , 81 ]. In general, the food-sector applications of brewers’ spent grain were comprehensively discussed in the excellent review works of McCarthy et al. [ 82 ], Lynch et al. [ 48 ], and lately Rachwał et al. [ 83 ].

Energy production

Like other types of waste biomass, BSG was also investigated in energy production, which may be implemented within the brewery, leading to reduced production costs [ 84 ]. It can be directly combusted. However, it may cause problems related to the high nitrogen content and resulting generation of nitrogen oxides [ 85 ]. Such an effect can be reduced by the application of pyrolysis [ 86 ]. Another possibility is converting BSG into charcoal bricks, which increases its calorific value from ~ 20 to 27 MJ/kg [ 87 , 88 ]. Multiple works also reported microbial fermentation of brewers’ spent grain into bioethanol [ 89 , 90 , 91 ] or biogas [ 92 , 93 , 94 , 95 ], which can be applied as biofuels.

Fermentation

Considering fermentation, BSG was investigated as a growth medium [ 96 ], e.g., substitute of sucrose or glucose in the lactic fermentation [ 97 , 98 , 99 ], medium for pullulan production [ 100 ], and introduced into manufacturing of xylitol [ 101 , 102 , 103 ] or citric acid [ 104 ]. The application of wastes and residues for fermentation is a very common and often investigated approach [ 105 ].

Among the mentioned fermentation products, lactic acid is an exciting compound for polymer technology. It is commonly applied in poly(lactic acid) manufacturing—one of the most popular biodegradable, thermoplastic polyesters [ 106 ]. Over the last years, it attracted much attention due to the application in 3D printing [ 107 ]. Moreover, due to the current law regulations, its popularity in manufacturing packaging materials is increasing, often combined with other, less expensive materials like thermoplastic starch [ 108 ].

Except for lactic acid, other BSG fermentation products, which could be applied in polymer technology are citric acid [ 109 ] and propionic acid [ 110 ]. The first one can be applied as a co-monomer in manufacturing of polyesters [ 111 , 112 , 113 , 114 ] or as a crosslinking agent [ 115 , 116 ]. Propionic acid is a substrate in the production of polymers based on cellulose derivatives, such as cellulose propionate [ 117 ]. Their popularity is growing over the last years due to the current pro-environmental trends related to bio-based polymer materials and their potential novel applications, e.g., in 3D printing [ 118 , 119 , 120 ].

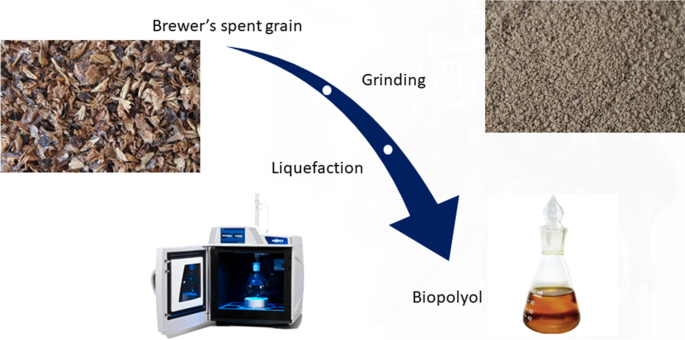

Figure 4 summarizes the potential applications of BSG fermentation products in polymer technology. Nevertheless, to the best of our knowledge, no works deal with the application of BSG fermentation products in polymer technology. More details related to the recent developments in the biotechnological valorization of these by-products were presented recently in the comprehensive review work by Puligundla and Mok [ 121 ].

Potential applications of BSG fermentation products in polymer technology

Extraction of celluloses and lignin

Except for the microbial conversion, various compounds present in BSG, which may find application in polymer technology, can be extracted using different techniques [ 122 , 123 , 124 ]. Among the most noticeable components of BSG in terms of polymer technology are celluloses and lignin [ 125 ]. They could be applied as fillers for composites and intermediates in manufacturing other raw materials used in polymer technology.

Mishra et al. [ 126 ] presented the multi-stage process of BSG conversion into cellulose nano-fibers consisting of alkali treatments and bleaching. They isolated nanosized fibers with an average diameter of 4.6 nm, shown by atomic force microscopy. Similar fibers are often investigated as fillers for polymer nanocomposites [ 127 , 128 , 129 ]. The efficient isolation of fibers and removal of other components of BSG was confirmed by thermogravimetric analysis (lack of decomposition step attributed to the presence of lignin) and X-ray diffractometry (gradual increase in crystallinity index). Similar observations were made by dos Santos et al. [ 130 ].

Mussatto et al. [ 131 ] investigated the recovery of lignin from BSG. The by-product was subjected to the soda pulping process, comprehensively described in other work [ 132 ]. The resulting black liquor was treated with sulfuric acid, which enabled the separation of lignin by precipitation. Except for the lignin, the investigated process enabled the removal of ferulic, p -coumaric, p -hydroxybenzoic, vanillic, and syringic acids from black liquor. Such an effect points to the presence of these compounds in obtained lignin, which could be applied, e.g., as a filler for wood-polymer composites.