- Platform OUR PRODUCT & MODULES Connected CMMS Maintenance Management Service Management Vendor Management Connected Workplace Work Order Management Inspections Asset Management Connected Buildings Utility Tracking & Benchmarking Energy Analytics & BI Cloud based Optimization Fault Detection & Diagnostics Connected Refrigeration Refrigeration Energy Optimization Remote Multi-site Monitoring Refrigerant Leak Compliance PLATFORM OVERVIEW Facilio O&M Platform Facilio IoT Edge Integrations Schedule time with a solutions expert

- Solutions By Industry Commercial Portfolios A complete real estate O&M suite built to boost building value Corporate Facilities Maximize efficiency and make 'experience' the new dimenson of your enterprise FM Services Empower workforce, make data-backed decisions, and create more value to clients Retail Enhance the in-store customer experience, operational efficiency, and run energy efficient stores across your portfolio. By Outcome Data-driven Portfolio Operations Remove friction points and ensure insight-led operations across buildings and teams FM Visibility More than just a CaFM/CMMS - gain contextual insights on contracted services 360* Asset Lifecycle Visualise assets, track performance, and streamline lifecycle processes Continuous Sustainability Close the energy efficiency gap by embedding sustainability with operations Customer Success at Facilio

Quick Guides

Our collection of playbooks on data-driven building operations to fuel efficiency. Get all the insights you need to improve portfolio operations.

Facilio Blog

Noteworthy articles on all things building ops. Strategies and videos on how to improve maintenance, sustainability, and tenant retention.

What's New with Facilio

We're constantly working to improve your Facilio experience so you can fasttrack your property operations to success. Here's what's new!

- Partners Become a Partner Locate a Partner AWS

- Company About Futureproof Careers Customers Contact Us Events

Maintenance Management

Exploring the relationship between maintenance & reliability.

Manaswini Rao

Maintenance comes into action when something breaks down, and you have to troubleshoot and repair problems in equipment or systems. On the other hand, reliability concerns the equipment's design and functionality that define its ability to function seamlessly.

This article will cover the main differences between maintenance and reliability, their core pillars, and key trends.

- What is maintenance?

Maintenance involves managing assets, equipment, and systems to overcome asset failure and ensure operational continuity.

A study by the International Association of Maintenance Management Professionals (IAMMP) found that maintenance-related issues account for 10-15% of unplanned downtime in manufacturing industries, which can cost businesses up to $260,000 per hour.

Planning the right kind of maintenance framework to determine monitoring techniques, maintenance activities, and schedules is critical to avoiding costly disruptions.

Maintenance maximizes the hassle-free functioning and longevity of facilities, assets, and entire businesses by proactively predicting issues, improving equipment efficiency, derisking risks & safety hazards, and ensuring compliance.

There are four primary types of maintenance: Reactive, preventive, predictive, and breakdown maintenance.

Reactive maintenance (RM) : Also known as corrective maintenance, RM aims to restore the equipment to its original functionality once an asset or equipment has malfunctioned. This is typically applied to assets that aren’t very expensive to replace or do not pose threats to operational continuity.

Preventative maintenance (PM) : Also known as routine maintenance, preventive maintenance involves scheduled inspections and repairs to prevent equipment failure in the future.

Predictive maintenance (PdM) : It uses data and analysis to predict equipment failure based on predefined failure modes. This methodology uses PdM tech (or CMMS software) and IoT beacons for real-time monitoring and insights into asset performance.

Breakdown maintenance : Also known as run-to-failure maintenance, breakdown maintenance is used to repair or exchange the damaged part in case inspection, and other maintenance activities aren't possible due to the breakdown of assets.

Implementing the right maintenance framework and monitoring techniques is essential to improve equipment efficiency, derisk risks and safety hazards, ensure compliance, and maximize the hassle-free functioning and longevity of facilities and businesses.

So how do you assess if your maintenance programs are effective?

Enter: Reliability metrics.

- Looking for a CMMS that does more than record-keeping?

- What is reliability?

Reliability refers to the ability of a maintenance program to ensure the reliability of assets, systems, and equipment. It’s a measure of how well your maintenance efforts ensure continuity in operations with minimal downtime.

Here are some formulas, pros and cons, and examples of different reliability metrics commonly used in equipment reliability analysis:

Failure rate (λ)

The failure rate is a measure of the frequency at which a system or component is likely to fail over a certain period of time.

It is often expressed as the number of failures per unit of time (e.g., failures per hour or per year).

If a manufacturer wants to understand the failure rate of a new production line that has been operating for 1000 hours and has experienced 5 failures, λ = 5 / 1000 = 0.005 failures per hour.

- Pro: Simple to calculate, provides a measure of the frequency of failures

- Con: Does not take into account the age of the equipment or the severity of the failures

Mean time between failures (MTBF)

MTBF is a measure of the average time that a system or component can run without experiencing a failure.

It is calculated by dividing the total operating time by the number of failures that occur during that time.

If a fleet of trucks has been operating for a total of 10,000 hours and has experienced 20 failures, the MTBF = 10,000 / 20 = 500 hours.

- Pro: Takes into account the age of the equipment and provides a measure of the average time between failure

- Con: Assumes a constant failure rate over time and may not be appropriate for equipment with a high initial failure rate.

Mean time to failure (MTTF)

MTTF is similar to MTBF, but it is specifically used for systems or components that are repaired or replaced after a failure occurs.

It is the average time that a system or component can run before a failure occurs that requires repair or replacement.

If an electronic component has been operating for a total of 1000 hours and has experienced 10 failures and 5 suspensions, the MTTF = 1000 / (10 + 5) = 66.67 hours.

- Pro: Takes into account the age of the equipment and provides a measure of the average time until the next failure.

- Con : Assumes a constant failure rate over time and may not be appropriate for equipment with a high initial failure rate.

Availability

Availability is the measure of the proportion of time that a system or component is operational and available to perform its intended function.

It is often expressed as a percentage and takes into account both scheduled downtime for maintenance and unscheduled downtime due to failures or other issues.

If a power plant has been operating for 24 hours a day for a year, but has been shut down for 50 hours for maintenance, the Availability = (24 x 365 - 50) / (24 x 365) = 98.6%.

- Pro : Provides a measure of how often the equipment is available for use

- Con : Does not take into account the severity of the downtime

Reliability

Reliability is the measure of the ability of a system or component to perform its intended function over a certain period of time. It takes into account the probability of failure and the consequences of failure.

A reliable system or component is one that is unlikely to fail and can be depended on to perform its intended function consistently.

If a machine has been operating for 2000 hours and has experienced 150 hours of downtime, the Reliability = 2000 / (2000 + 150) = 0.93 or 93%.

- Pro : Provides a measure of the probability that the equipment will operate without failure over a given time period

- Con : Assumes a constant failure rate over time, does not take into account the severity of the downtime

While each metric has its pros and cons, they all provide valuable insights into the reliability of equipment and can help maintenance teams optimize their maintenance activities to increase uptime and reduce costs.

Ultimately, achieving high equipment reliability requires a comprehensive approach that includes preventive maintenance, predictive maintenance, and asset management strategies.

Manage 360° asset lifecycles from a centralized platform

- What is the objective of maintenance & reliability?

The primary objective of maintenance and reliability is to ensure the seamless and efficient functioning of equipment, systems, and facilities during their lifetime.

The ultimate goal is to minimize downtime, reduce maintenance costs, and increase the overall efficiency and effectiveness of an organization's operations.

A McKinsey study concluded that maintenance and reliability could reduce machine downtime by 30-50% and extend equipment lifespan by 20-40%.

A comprehensive maintenance and reliability program helps businesses ensure their assets are functioning at their highest level and continue to meet the needs of their customers and stakeholders.

- The five pillars of maintenance and reliability

The five pillars of maintenance and reliability are business processes, workforce management, materials management, asset management, and performance management.

- Business Processes: The management systems and processes that support maintenance activities, such as work order management , planning and scheduling, and performance metrics.

- Workforce Management: The practices and tools used to manage and develop the maintenance workforce, including training, performance management, and succession planning.

- Materials Management: The processes and systems used to procure, store, and manage maintenance-related materials, including inventory management, vendor management, and procurement strategies.

- Asset Management: The strategies and practices used to manage the physical assets of the organization, including maintenance strategies, asset performance management, and lifecycle analysis.

- Performance Management: The systems and tools used to measure and analyze maintenance and reliability performance, including KPIs, data analysis, and continuous improvement processes.

To achieve error-free asset performance, it is essential to empower your team to execute, monitor, and iterate maintenance and reliability measures.

Using a smart Computerized Maintenance Management System (CMMS) like Facilio helps manage end-to-end asset lifecycles with 360-degree operational visibility and remote monitoring and control of equipment performance across locations in real-time.

- Maintenance and reliability trends in 2023

Time is money rings true for maintenance and reliability managers.

Let’s look at four key maintenance and reliability trends changing the game in 2023:

- Digital transformation: Digitizing O&M processes with CMMS built for modern use cases will be essential for operational efficiency. Organizations are increasingly switching from reactive to proactive methods of monitoring and maintaining critical equipment and spaces.

- Predictive analytics: According to a report by Precedence Research , the predictive maintenance market will grow to $10.79 billion in 2023. Utilizing IoT devices such as sensors, artificial intelligence, and digital twins can help identify patterns and predict equipment behavior to enable timely maintenance and improve reliability.

- Workplace safety: Automating redundant and mechanical tasks can free up employees’ time and allow them to focus on the most important aspects of their roles. Providing a safe work environment for maintenance staff enhances the quality of work and job market appeal.

- Virtual technologies: Augmented reality (AR) and virtual reality (VR) are becoming crucial for on-site inspections. AR enables professionals to place a camera in front of the machine and receive real-time notes and insights on a screen, facilitating timely maintenance and inspections.

- How does a CMMS help with maintenance & reliability?

According to a survey conducted by Plant Services , training new M&R personnel is the industry's biggest challenge in 2023, with 31% of people voting for this problem.

Some of the most common challenges are:

- Training new M&R personnel – 31%

- Supply chain issues – 30%

- M&R labor shortages – 26%

- Maintenance debt/backlog – 14%

A CMMS software centralizes all information for effectively managing maintenance activities, asset management, and enabling data-driven decision-making.

This can further improve equipment reliability with predictive analysis , reduce maintenance costs, and optimize your maintenance operations.

What’s more, the implementation of effective CMMS will aid in incorporating reliability-centered maintenance (RCM) strategies that further enhance productivity, cost optimization, and increased O&M efficiency.

Case Study: IDC Study - How CMMS is Evolving Beyond Asset Management & Maintenance

Here's how a CMMS can improve maintenance and reliability:

- Better planning and scheduling: CMMS centralizes work orders and maintenance schedules, reducing downtime and optimizing workloads.

- Improved asset management: It improves asset management by monitoring equipment performance, preventing breakdowns, and optimizing asset utilization.

- Enhanced inventory management: It helps ensure that the right parts are in store when they are needed, reducing downtime and minimizing the cost of spare parts.

- Streamlined communication: It streamlines communication by providing real-time access to work orders and maintenance schedules.

- Better data analysis: Data analysis from CMMS provides insights to improve maintenance and reliability by identifying areas for improvement.

Facilio's cloud-based Connected CMMS solution provides a powerful suite of features that enable you to streamline and optimize your maintenance operations, boost equipment reliability, and maximize uptime.

It offers AI-powered analytics and predictive maintenance capabilities that automatically identify potential issues before they occur and prevent them from becoming costly problems.

Further, with powerful workflows and automated work orders, from requests to resolution and quotes for service, you can finally bid goodbye to repetitive, tedious maintenance tasks and focus on important things that deserve your time and expertise.

Take the first step towards a more efficient and reliable maintenance system today by scheduling a demo today !

- Go beyond just managing assets and maintenance tasks

Discover the power of a Connected CMMS that unifies your people, processes, and systems at scale.

- Manage 360° asset lifecycles from a centralized platform

Gain 360° visibility into portfolio-wide O&M

We are Hiring!

© 2024 Facilio.Inc | All rights reserved

connect with us

3.3 Maintenance and Reliability (Powerpoint)

For this activity, you will assume the role of an aviation maintenance manager. As the aviation maintenance manager, you are responsible for all maintenance actions and for maintaining aircraft in a serviceable condition. For this assignment, conduct research to identify a current aviation maintenance challenge/issue. In your briefing, you will identify the maintenance issue and provide a maintenance strategy to correct the maintenance issue.

Your presentation must include a minimum of five, but no more than eight, slides not including the title slide or reference slide, have embedded audio, and include speaker notes.

Keep in mind that as a minimum your presentation must:

- Identify a current aviation maintenance issue of your choosing.

- Explain the impact of the maintenance issue.

- Define how scheduled maintenance cycles can be used as part of your strategy in addressing the issue.

- Determine and support the role of a reliability program in ensuring that your strategy corrects the issue.

We are a custom essay writing service provider with an aim of assisting students in their academic endeavors. We achieve this by employing professional writers who draft quality papers for any academic level. Our goal is to help students perform better and emerge successful in their studies.

With running systems in place such as the money-back guarantee, plagiarism free papers, and confidentiality guarantees, we believe that we are the most efficient online essay writing service provider.

Quick Links

- Privacy Policy

- Money Back Guarantee

- Terms and conditions

- Plagiarism Free Papers

Tel: +1 (231) 242-8514 Mobile: +1 (231) 242-8514 E-mail: [email protected]

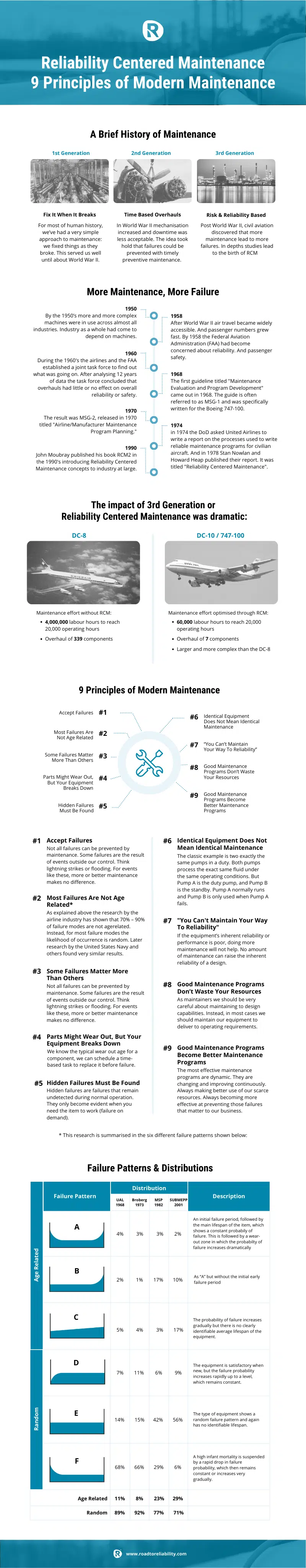

9 Principles of Effective PM Programs based on Reliability Centered Maintenance (RCM)

WRITEN BY: Erik Hupje

15 min read

Table of Contents

In this article, I provide a brief history of the development of Reliability Centered Maintenance (RCM). And from there we explore 9 principles derived from RCM that will help you build an effect ive Preventive Maintenance Program. As a maintenance & reliability practitioner, you should know these RCM principles and live by them so that you have an evaluation criteria for creating a cost effective maintenance strategy.

Fix it when it breaks

For most of human history, we’ve had a very simple approach to maintenance: we fixed things as they broke. Fix things as failure occurs. This served us well from our early days huddled around campfires until about World War II.

In those days, industries were not very complex or highly mechanized. The downtime was not a major issue and preventing equipment failures wasn’t a concern.

Figure 1: 1st Generation Maintenance was a long way from modern-day RCM

At the same time, most equipment in use was simple and more importantly, it was over-designed. This made equipment reliable and easy to repair. And most plants operated without any preventive maintenance in place. Maybe some cleaning, minor servicing, and lubrication, but that was about it.

This simple ‘fix it when it breaks’ approach to maintenance is often referred to as First Generation Maintenance. A failure occurs, no big deal.

Things changed during World War II

Wartime increased the demand for many, diverse products. Yet at the same time, the supply of industrial labour dropped. Productivity became a focus. And mechanization increased. By the 1950’s more and more complex machines were in use across almost all industries. Industry as a whole had come to depend on machines.

And as this dependence grew, it became more important to reduce equipment downtime. ‘Fix it when it’s broken’ no longer suited industries.

Figure 2: 2nd Generation Maintenance was dominated by time-based overhauls

A focus on preventing equipment failures emerged. And the idea took hold that failures could be prevented with a suitable preventive task at the right time. In other words, the industry moved from breakdown maintenance to time-based preventive maintenance. Fixed interval overhauls or replacements to prevent failures became the norm.

This approach to preventive maintenance is known as Second Generation Maintenance.

More maintenance, more equipment failures

Between the 1950s and 1970s, the third generation of maintenance was born in the aviation industry.

After World War II, air travel became widely accessible. And passenger numbers grew fast. By 1958 the Federal Aviation Administration (FAA) had become concerned about reliability. And passenger safety.

At the time the dominant thinking was that components had a specific life. That components would fail after reaching a certain “age”. Replacing components before they reached that age would thus prevent failure. And that was how you ensured equipment reliability and passenger safety.

In the 1950’s and 1960’s the typical aircraft engine overhaul was every 8,000 hours. So when the industry was faced with an increasing number of failures, the conclusion was easy. Obviously component age must be less than the 8,000 hours that was being assumed. So, maintenance was done sooner. The time between overhauls reduced.

Easy, right?

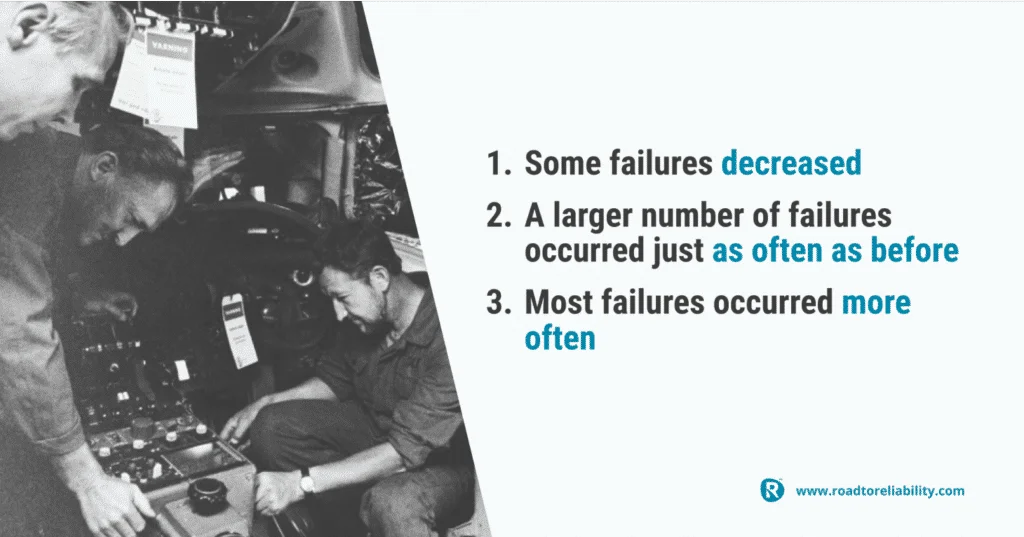

But, increasing the amount of preventive maintenance had three very unexpected outcomes. Outcomes that eventually turned the maintenance world upside down.

First of all, the occurrence of some failures decreased. That was exactly what everybody expected to happen. All good.

The second outcome was that a larger number of equipment failures occurred just as often as before. That was not expected and slightly confusing.

The third outcome was that most failures occurred more frequently. In other words, more maintenance leads to more failures. That was counter-intuitive. And a shock to the system.

Figure 3: the findings that led to R CM were a shock to the system

The birth of Reliability Centered Maintenance (RCM)

To say that the results frustrated both the FAA and the airlines would be an understatement. The FAA worried that reliability had not improved. And the airlines worried about the ever-increasing maintenance burden.

So during the 1960’s the airlines and the FAA established a joint task force to find out what was going on. After analyzing 12 years of data the task force concluded that overhauls had little or no effect on overall reliability or safety.

For many years engineers had thought that all equipment had some form of wear out pattern. In other words, that as equipment aged the likelihood of failure increased. But the study found this universally accepted concept did not hold true.

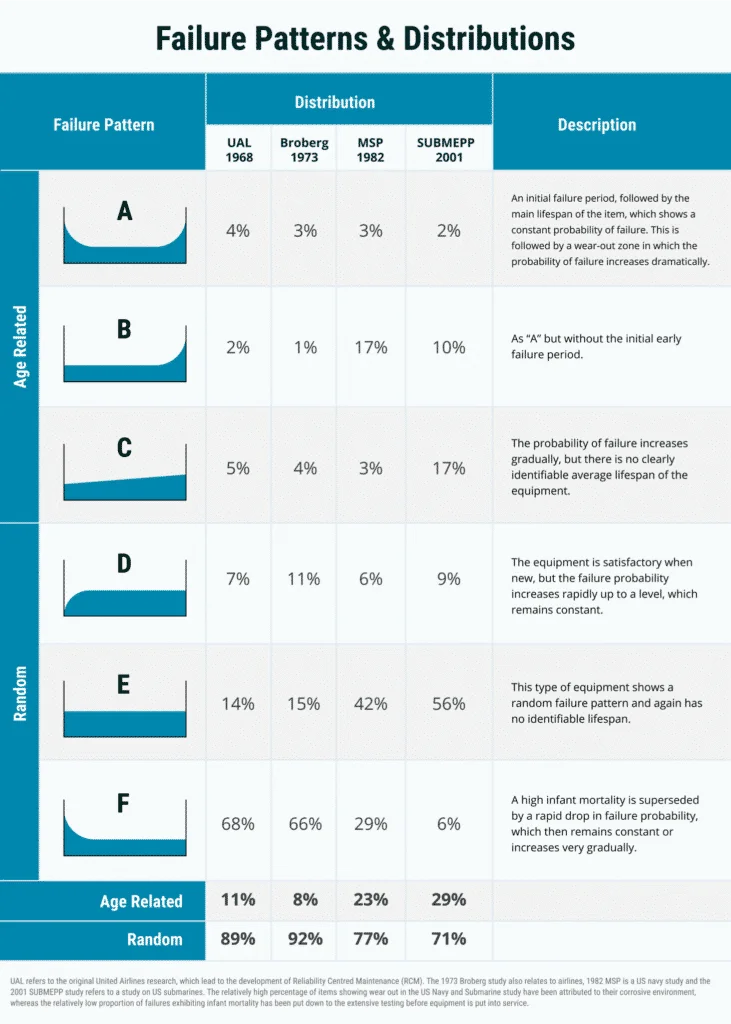

Instead, the task force found six patterns describing the relationship between age and failure. And that the majority of failures occur randomly rather than based on age.

The task force findings were used to develop a series of guidelines for the aviation industry and airplane manufacturers on the development of reliable maintenance schedules for airplanes.

The first guideline titled “Maintenance Evaluation and Program Development” came out in 1968. The guide is often referred to MSG-1 and was specifically written for Boeing 747-100.

The maintenance schedule for the 747-100 was the first to implement Reliability Centered Maintenance program concepts using MSG-1. And it reduced maintenance costs by 25% to 35% compared to prior practices.

As a result, the aviation industry lobbied to remove all the 747-100 terminology from MSG-1. They wanted the maintenance schedules for all new commercial planes designed using the same process.

The result was MSG-2, released in 1970 titled “Airline/Manufacturer Maintenance Program Planning”.

Figure 4: RCM led to the birth of 3rd generation maintenance thinking

The first applications of Reliability-Centered Maintenance (RCM)

The move to 3rd Generation or Reliability-Centered Maintenance as outlined MSG-1 and MSG-2 was dramatic.

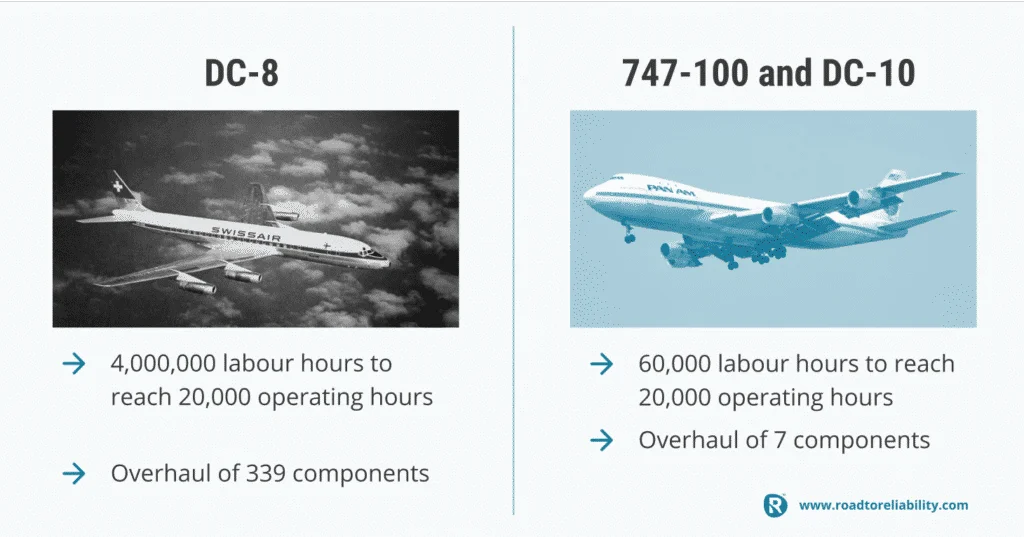

The DC-8’s maintenance schedule used traditional, 2nd Generation Maintenance concepts. It required the overhaul of 339 components and called for more than 4,000,000 labour hours before reaching 20,000 operating hours.

Compare that to the maintenance schedule for the Boeing 747-100, developed using MSG-1. It required just 66,000 labour hours before reaching the same 20,000 operating hours!

Another interesting comparison is to compare the number of items requiring fixed-time overhauls. The maintenance for the DC-10 was developed using MSG-2 and required the overhaul of just 7 items versus the 339 on the DC-8.

And both the DC-10 and Boeing 747-100 were larger and more complex than the DC-8.

Impressive results. And the US Department of Defense (DoD) thought so too.

Figure 5: the benefits of a reliability centered maintenance program for the airline industry was massive

The US Department Of Defense gets involved in RCM

So in 1974, the DoD asked United Airlines to write a report on the processes used to write reliable maintenance programs for civilian aircraft. And in 1978 Stan Nowlan and Howard Heap published their report. It was titled “Reliability Centered Maintenance”.

Since then a lot more work was done to progress the cause of Reliability-Centered Maintenance. The airline industry has moved to MSG-3. John Moubray published his book RCM2 in the 1990’s introducing Reliability Centered Maintenance concepts to the industry at large.

Nowadays, successful implementation of RCM programs are defined through international standards. But it’s the work done in the 60’s and 70’s that culminated in the Knowlan & Heap report in 1978 that all modern-day RCM approaches can be traced back to.

That’s now more than 40 years ago. So any Maintenance & Reliability professional should be familiar with it by now. It’s been around long enough. It’s well documented. And widely available.

Unfortunately, we find that’s not the case. The principles of modern maintenance as developed in the journey to Reliability-Centered Maintenance are not always known or understood. Let alone applied.

The rest of this article will outline those principles. They should underpin any sound maintenance program.

One of the best summaries of these principles can be found in the NAVSEA RCM Handbook. 4 I would highly recommend reading it. It is well written and easy to understand. And the following Principles of Modern Maintenance are very much built on the ‘Fundamentals of Maintenance Engineering’ as described in the NAVSEA manual.

What is Reliability Centered Maintenance (RCM)?

So, with all that history behind us, the question now is this:

What is RCM?

There are plenty of definitions out there, including many poor ones. To save us time, I’ve taken the definition from various reputable sources such as Weibull, Aladon, John Moubray, and Anthony ‘Mac’ Smith. And mixing in my personal experience with RCM, I’ve summarised what RCM is:

RCM is NOT a tool or a piece of software like your computerized maintenance management system (CMMS) .

It is an internationally defined, structured decision-making process.

We use it to define or optimise our PM program, focusing on preventing system failures rather than preserving equipment.

It is the gold standard when it comes to optimising our PM programs. When it comes to developing & improving PM programs, RCM is the most robust, most standardised process that is proven to yield exceptional results.

When done well, an RCM process will give you a highly effective and efficient preventive maintenance program .

The most fundamental requirement of any RCM process is that it must adequately and completely answer the following seven questions: 1. What are the functions and associated performance standards for the asset in its current operating context? 2. In what way can the asset fail to fulfill its functions? 3. What causes each possible functional failure? 4. What happens when each functional failure occurs? 5. In what way does each failure mode matter? 6. What should we do to predict or prevent each failure mode? 7. What should we do if a suitable preventive task cannot be found? When done well, a Reliability Centered Maintenance program (RCM) will deliver highly effective and efficient PM programs. RCM processes are defined through a set of international standards: SAE JA1011 titled “ Evaluation Criteria for Reliability Centered Maintenance Processes ” and SAE standard JA1012 titled “ A Guide to The Reliability Centered Maintenance Standard “.

However, for a successful implementation of a reliability centered maintenance program, there are two things you need to succeed:

- Deep knowledge and experience of both the RCM process, as well as the plant and equipment that is being analyzed

- Significant resources and effort to yield results.

Because of this, you need to be wise about when, where, and how you implement a reliability centered maintenance program. You don’t want to implement it everywhere in your organisation. If you don’t pick the right situation, and deploy it when it is not the most appropriate, you’ll spend so much money without getting the results you’re looking for. You’ll simply be increasing your maintenance costs for nothing.

Many organisations don’t realise this and try to implement RCM everywhere. And when they fail, or see that RCM is too expensive, that’s when they say things like—

“Enough of this RCM nonsense, it’s too expensive and beyond our maintenance budget.”

Successful implementation of reliability centered maintenance should only be used for a small number of your equipment— the most troublesome, most expensive, or most impactful. That way, they can have reduced maintenance costs.

9 Principles from RCM to create an effective preventive maintenance program

Whether you are developing a new maintenance program. Or improving the maintenance program for an existing plant. All reliable maintenance programs should be based on the following Principles of Modern Maintenance:

Principle #1: Accept Failures

Principle #2: Most Failures Are Not Age-Related

Principle #3: Some Failure Consequences Matter More Than Others

Principle #4: Parts Might Wear Out, But Your Equipment Breaks Down

Principle #5: Hidden Failures Must Be Found

Principle #6: Identical Equipment Does Not Mean Identical Maintenance Strategies

Principle #7: “You Can’t Maintain Your Way To Reliability”

Principle #8: Good Maintenance Programs Don’t Waste Your Resources

Principle #9: Good Maintenance Programs Become Better Maintenance Programs

As a Maintenance & Reliability professional, you must understand these principles so that you can create an effective maintenance strategy and build it into your computerized maintenance management system (CMMS).

You must practice them.

You must live by them.

Principle #1: Accept failures

Not all failures can be prevented by maintenance. Some failures are the result of events outside our control. Think lightning strikes or flooding. For events like these, more or better maintenance makes no difference. Instead, the consequences of these events should be mitigated through design.

And maintenance can do little about failures that are the result of poor design, lousy construction or bad procurement decisions.

In other cases, the impact of the failure is low so you simply accept the failure (think general area lighting). By allowing these to run to failure, you are increasing the cost effectiveness of your maintenance strategy.

So, good maintenance programs do not try to prevent all failures. Good maintenance plans and programs should accept some level of failure and be prepared to deal with the failures they accept (and deem credible).

Principle #2: Most failure modes are not age-related

As explained above the RCM research by the aviation industry has shown that 70% – 90% of failure modes are not age-related. Instead, for most failure modes the likelihood of occurrence is random. Later research by the United States Navy and others found very similar results.

This research is summarised in the six different failure patterns shown below:

Figure 6: the failure patterns from various reliability centered maintenance studies

Apart from showing that most failure modes occur randomly. These failure patterns also highlight that infant mortality is common. And that it typically persists. That means that the probability of failure only becomes constant after a significant amount of time in service.

Don’t interpret Curves D, E, and F to mean that (some) items never degrade or wear out. Everything degrades with time, that’s life. But many items degrade so slowly that wear out is not a practical concern. These items do not reach wear out zone in normal operating life.

So what do these patterns tell us about our reliable maintenance programs?

Historically, maintenance was done in the belief that the likelihood of failure increased over time (first generation maintenance thinking). It was thought that well-timed maintenance could reduce the likelihood of failure. RCM has taught us that for at least 70% of equipment this simply is not the case.

For the 70% of failure modes which has a constant probability of failure, there is no point in doing time-based life-renewal maintenance tasks like servicing or replacement.

It makes no sense to spend maintenance resources to service or replace an item whose reliability has not degraded. Or whose reliability cannot be improved by that maintenance task.

In practice, this means that 70% – 90% of equipment failure modes would benefit from some form of condition based maintenance. And only 10% – 30% can be effectively managed by time-based replacement or overhaul.

Yet most of our PM programs are full of time-based replacements and overhauls.

Strictly speaking, the studies that documented the fact that 70% to 90% of failure modes were random only found this in specific industries and applications. And they were not conducted in major industries like oil & gas, mining, chemical manufacturing, food processing, power generation etc. So you could therefore dismiss these results with a simple “well, we’re in a different industry, so obviously this doesn’t apply to us”. I strongly believe this principle applies to all heavy industries (more on that in a future article) and would strongly encourage you to approach this with the question “Why wouldn’t it apply to us?” and then carefully examine what you could gain from applying this principle.

Principle #3: Some failure consequences matter more than others

When deciding whether to do a maintenance task consider the consequence of not doing it. What would be the consequence of letting that specific failure mode occur?

Avoiding that consequence is the benefit of your maintenance.

The return on your investment.

And that is exactly how maintenance should be seen: as an investment. You incur maintenance costs in return for a benefit in sustained safety and reliability. And as with all good investments, the benefit should outweigh the original investment.

So, understanding failure consequences is key to developing a good maintenance program. One with a good return on investment.

Just as not all failures have the same probability, not all failures have the same consequence.

Even if it relates to the same type of equipment.

Consider a leaking tank. The consequence of a leaking tank is severe if the tank contains a highly flammable liquid. But if the tank is full of potable water the consequence might not be of great concern.

But what if the water is required for fire fighting?

The same tank, the same failure mode, but now we might be more concerned. We would not want to end up in a scenario of not being able to fight a fire because we had an empty tank due to a leak.

Apart from the consequence of a failure you also need to think about the likelihood of the failure actually occurring.

Maintenance tasks should be developed for dominant and important failure modes only. Those failures that occur frequently and those that have serious consequences but are less frequent to rare. Avoid assigning maintenance to non-credible failure modes. And avoid analyzing non-credible failure modes. It eats up your scarce resources for no return.

A maintenance program should consider both the consequence and the likelihood of failures. And since Risk = Likelihood x Consequence we can conclude that good maintenance programs are risk-based.

Good maintenance programs use the concept of risk to assess where to use our scarce resources to get the greatest benefit. The biggest return on our investment.

Principle #4: Parts might wear out, but your equipment breaks down

A ‘part’ is usually a simple component, something that has relatively few failure modes. Some examples are the timing belt in a car, the roller bearing on a drive shaft, the cable on a crane.

Simple items often provide early signals of potential failure, if you know where to look. And so we can often design a task to detect potential failure early on and take action prior to failure.

For those simple items which do “wear out” there will be a strong increase in the probability of failure past a certain age. If we know the typical wear outage for a component, we can schedule a time-based task to replace it before failure.

When it comes to complex items made of many “simple” components, things are different.

All those simple components have their own failure modes with its own failure pattern. Because complex items have so many, varied failure modes, they typically do not exhibit wear outage. Their failures do not tend to be a function of age but occur randomly. Their probability of failure is generally constant as represented by curves E and F.

Most modern machinery consists of many components and should be treated as complex items. That means no clear wear outage. And without clear wear out age performing time-based overhauls is ineffective. And wasteful of our scarce resources.

Only where we can prove that an item has wear outage does performing time-based overhaul or component replacement make sense.

Principle #5: Hidden failures must be found

Hidden failures are failures that remain undetected during normal operation. They only become evident when you need the item to work (failure on demand). Or when you conduct a test to reveal the failure – a failure finding task.

Hidden failures are often associated with equipment with protective functions. Something like a high-high pressure trip. Protective functions like these are not normally active. They are only required to function by exception to protect your people from injury or death. To protect the environment from a major impact or protect our assets from major damage. This means we pretty much always conduct failure finding maintenance tasks on equipment with protective functions.

To be clear, a failure finding task does not prevent failure. Instead, a failure finding task does exactly what its name implies. It seeks to find a failure and identify failure modes. A failure that has already happened, but has not been revealed to us. It has remained hidden.

We must find hidden failures and fix them before the equipment is required to operate.

Principle #6: Identical equipment does not mean identical maintenance strategies

Just because two pieces of equipment are the same doesn’t mean they need the same maintenance. In fact, they may need completely different and appropriate maintenance tasks.

The classic example is two exactly the same pumps in a duty – standby setup. Same manufacturer, same model. Both pumps process the exact same fluid under the same operating conditions. But Pump A is the duty pump, and Pump B is the standby. Pump A normally runs and Pump B is only used when Pump A fails.

When it comes to failure modes Pump B has an important hidden failure mode: it might not start on demand. In other words, when Pump A fails or under maintenance, you suddenly find that Pump B won’t start. Oops.

Pump B doesn’t normally run so you wouldn’t know it couldn’t start until you came to start it. That’s the classic definition of a hidden failure mode. And a hidden failure mode like this requires a failure finding task i.e. you go and test to see if Pump B will start. But you don’t need to do this for Pump A because it’s always running (unless when it’s off or failed).

So when building a maintenance program you must consider the operating context (RCM is very clear on this, but other approaches sometimes neglect operating content).

A difference in criticality can also lead to different maintenance strategies. Safety or production critical equipment will need more monitoring and testing than the same equipment in low criticality service.

It’s important to reinforce that identical equipment may need different maintenance strategies. This is far too often forgotten or simply ignored for convenience. But you could find yourself facing critical failures by ignoring this basic concept. Especially if you use a library of preventive maintenance tasks.

Principle #7: “You can’t maintain your way to reliability”

I love this quote from Terrence O’Hanlon and it’s so very true. Maintenance can only preserve your equipment’s inherent design reliability and performance.

If the equipment’s inherent reliability or performance is poor, doing more maintenance will not help.

No amount of maintenance can raise the inherent reliability of a design.

To improve poor reliability or performance that’s due to poor design, you need to change the design. Simple.

When you encounter failures – defects – that relate to design issues you need to eliminate them.

Sure, the more proactive and more efficient approach is to ensure that the design is right, to begin with. But all plants startup with design defects. Even proactive plants. And that’s why the most reliable plants in the world have an effective defect elimination program in place.

Principle #8: Good maintenance programs don’t waste your resources

This seems obvious, right? But when we review PM programs we often find maintenance tasks that add no value. Tasks that waste resources and actually reduce reliability and availability.

It’s so common for people to say “whilst we do this, let’s also check this. It only takes 5 minutes.”

But 5 minutes here and there, every week or every month and we’ve suddenly wasted a lot of time. And potentially introduced a lot of defects that can impact equipment reliability down the line.

Another source of waste in our PM programs is trying to maintain a level of performance and functionality that we don’t actually need.

Equipment often have associated performance standards and are designed to do more than what they are required to do in their actual operating conditions. As maintainers, we should be very careful about maintaining to design capabilities. Instead, in most cases, we should maintain our equipment to meet operating requirements. Maintenance done to ensure equipment capacity greater than actually needed is a waste of resources.

Similarly, avoid assigning multiple tasks to a single failure mode. It’s wasteful and it makes it hard to determine which task is actually effective. Stick to the rule of a single, effective task per failure mode as much as you can. Only for very high consequence and important failure modes should you consider having multiple, diverse tasks to a single failure mode.

Most organisations have more maintenance to do than resources to do it with. Use resources on unnecessary maintenance, and you risk not completing necessary maintenance. And not completing necessary maintenance, or completing it late, increases the risk of failures.

And when that unnecessary maintenance is intrusive it gets worse. Experience shows that intrusive maintenance leads to increased failures because of human error. This could be simple mistakes. Or because of defective materials or parts, or errors in technical documentation.

A lot of maintenance is done with the equipment off-line. So doing unnecessary maintenance can also increase production losses.

So make sure you remove unnecessary maintenance processes from your system. Make sure you have a clear and legitimate reason for every task in your maintenance program. Make sure you link all effective tasks to a dominant failure mode. And have clear priorities for all effective tasks. That allows you to prioritise tasks. In the real world, we are all resource-constrained.

Principle #9: Good maintenance programs become better maintenance programs

The most effective maintenance programs are dynamic. They are changing and improving continuously. Always making better use of our scarce resources. Always becoming more effective at preventing those failures that matter to our business.

When improving your maintenance program, you need to understand that not all improvements have the same leverage:

First, focus on eliminating unnecessary maintenance tasks. This eliminates the direct maintenance of labour and materials and helps in reducing costs. But it also removes the effort required to plan, schedule, manage, and report on this work.

Second, change time-based overhaul or replacement tasks into condition-based tasks. Instead of replacing a component every so many hours, use condition based maintenance to assess how much life the component has left. And only replace the component when actually required.

And third, extend task intervals. Do this based on data analysis, operator and maintainer experience. Or simply on good engineering judgment. Remember to observe the results.

The shorter the current interval, the greater the impact when extending that interval. For example, adjusting a daily task to weekly reduces the required PM workload for that task by more than 80%.

This is often the simplest and one of the most effective improvements you can make.

Before I wrap up this article, I wanted to answer some of the most common FAQs relating your maintenance process and to a reliability centered maintenance program, and these are:

What is the difference between RCM and FMEA?

Failure Mode Effects Analysis (FMEA) or is a step in the reliability centered maintenance (RCM) process, but RCM does a lot more than just analysing functional failures. It focuses on defining functions, being clear on the operating context and selecting the right maintenance tasks based on the analysis of the different important failure modes.

I like to say that RCM is function-based, Preventive Maintenance Optimisation (PMO) is task-based, and Failure Mode Effects Analysis (FMEA) is equipment based, but all good analyses are failure mode based!

What are the types of reliability-centered maintenance?

Be very careful with the idea that there are ‘types of reliability centered maintenance’. People do talk about classical RCM and accelerated RCM. Classical RCM is the RCM process as originally defined by Nowland & Heap and now documented in SAE JA1011 and SAE JA1012. Accelerated RCM is an adaption of the classical RCM process, and there are quite a few variations – some are robust but others are not. Buyer beware!

What is the primary objective of RCM?

The primary objective of reliability-centered maintenance is to achieve the required reliability levels for a system, at optimised maintenance process and cost levels by focusing on the preservation of key functions.

Should we start with an RCM process to improve our reliability?

The first step to improving your reliability is to implement maintenance planning and scheduling. Without maintenance planning and scheduling in your maintenance strategies, you won’t have the time or resources to effectively implement RCM processes. The cost effectiveness of a good maintenance management process makes it a good investment.

I wrote this article based on a number of key sources listed below (and throughout the article). I strongly recommend getting yourself a copy of Moubray’s book on Reliability Centered Maintenance if don’t already own a copy. And I’d definitely get the NAVSEA Reliability Centered Maintenance (RCM) manual as it’s well-written and easy to understand:

- Moubray, J. (1997) Reliability Centered Maintenance Second Edition. Industrial Press. Available at: https://www.amazon.com/Reliability-Centered-Maintenance-Second-John-Moubray/dp/0831131462 .

- NAVSEA (2007) Reliability Centered Maintenance (RCM) Handbook [S9081-AB-GIB-010]. Available at: https://www.amazon.com/NAVSEA-Reliability-Centered-Maintenance-RCM-Handbook-ebook/dp/B00U1UJPKK .

- Allen, T. M. (2001) ‘U.S. Navy Analysis of Submarine Maintenance Data and the Development of Age and Reliability Profiles’. Available at: http://www.plant-maintenance.com/articles/SubmarineMaintenanceDataRCM.pdf .

- White Paper (no date) ‘What is Reliability Centered Maintenance?’ Available at: https://www.mainsaver.com/pdf/Reliability_Centered_Maintenance_White_Paper.pdf .

- Wikipedia (2017) Reliability-centered maintenance. Available at: https://en.wikipedia.org/wiki/Reliability-centered_maintenance

- NASA (2008) Reliability-Centered Maintenance Guide. Available at https://www.nasa.gov/sites/default/files/atoms/files/nasa_rcmguide.pdf

RCM Infographic

Feel free to share this RCM Infographic on your site, all we ask is that you include an attribution to https://reliabilityacademy.com

- TAGGING : Preventive Maintenance

Related Articles

Without planning and scheduling you will fail

Maintenance Planning & Scheduling is one of the 4 Essential Elements on the Road to Reliability™. Planning & scheduling, or work management as it’s often

Escaping the Vicious Cycle of Reactive Maintenance: The 4 Essential Steps on the Road to Reliability

Most industrial plants around the world are trapped in the vicious cycle of reactive maintenance. These plants and their teams silently suffer from low reliability,

Your CBM Efforts Will Fail Without Effective Planning & Scheduling

This article first appeared in reliable plant. You can read the first version of this article here. Many maintenance organisations around the world are reactive.

Level 54/111 Eagle Street

Brisbane City, QLD 4000

Phone: +61 (0)7 3040 7525

Email: [email protected]

Improve Reliability

Online Training

Reliability Resources

© 2017-2023 R2 Reliability Pty Ltd. All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings

Planning & Scheduling

Preventive Maintenance

Defect Elimination

Leadership & Culture

Planning & Scheduling Online Training

Preventive Maintenance Online Training

Scholarship Program

Articles & Blogs

Glossary & FAQ’s

Success Stories

Our Approach

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings

We train and coach your team to help you escape the vicious cycle of reactive maintenance and create a Reliable Plant.

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

Maintenance and Reliability Decisions

Published by Griffin Watson Modified over 5 years ago

Similar presentations

Presentation on theme: "Maintenance and Reliability Decisions"— Presentation transcript:

Operations Management Maintenance and Reliability Chapter 17

Total Productive Maintenance

Operations Management

MAINTENANCE MANAGEMENT Module 9

Oil Analysis Implementation Strategy J. Mike Weiksner BSME - Auburn University Years in Industry (EMO) Hold Certifications in Vibration & Oil.

Aggregate Planning in a Supply Chain

Maintenance At Your WWTP August 2010

Productive Maintenance

Maintenance and Reliability

All activities involved in keeping a system’s equipments working are the part of maintenances management. Maintenance of machine involves the efforts.

CHAPTER 1. MAINTENANCE “Act of causing to continue ” [New Oxford Dictionary]

Project Management. Maintenance and Reliability 14 Aug 2001.

Managing Quality Chapter 5.

Maintenance and Reliability Ross L. Fink. Maintenance All activities involved in keeping a system’s equipment in working order.

© 2011 Pearson Education, Inc. publishing as Prentice Hall 17 Maintenance and Reliability PowerPoint presentation to accompany Heizer and Render.

Maintenance Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill.

McGraw-Hill/Irwin Copyright © 2007 by The McGraw-Hill Companies, Inc. All rights reserved. 15S Maintenance.

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

By Industry

- Oil & Gas

- Power & Water Utilities

- Manufacturing

- Aviation & Defense

- Food and Beverage

- Reliability & Maintenance

- Asset Management

- Corporate Leadership

- Project Management

- Health, Safety & Environment

- Quality Assurance

- Manage asset strategies

- Develop asset strategies

- Optimize asset strategies

- Reduce cost

- Reduce downtime

- Improve reliability

- Design for reliability

- Solve recurring problems

- Build team capability

- Remote service options

How can we help

- Asset Performance Management

- Asset Strategy Management

- RAM Analysis

- Maintenance Strategy Development

- Maintenance Strategy Optimization

- Master Data Development

- Availability and Capacity Analysis

- Spare Parts Analysis

- Life Cycle Costing (LCC) Analysis

- Defect Elimination

- Reliability Centered Maintenance (RCM)

- Failure Mode and Effect Analysis (FMEA) Failure Mode, Effect and Criticality (FMECA)

- Task Based Maintenance (TBM) Analysis

- Vulnerability Analysis Assessment (VAA)

- Root Cause Analysis

- Cordant™ Asset Strategy

- Component Strategy Library

Asset Maintenance Simulation

- Reliability Integration Tool

- Cordant™ Defect Elimination

General Support

Cordant™ asset strategy support, copperleaf c55 support, isograph support.

- Privacy Policy

- Terms & Conditions

Advisory Services

- Mentoring & Support

Methodologies

- English Español English Español

Maintenance vs. Reliability: Optimal maintenance and reliability starts with better alignment

Author: Jason Apps

When it comes to organizational structure, maintenance and reliability are better together. True alignment, however, requires a better understanding of each function and the value they bring.

Maintenance and reliability are, in many ways, two sides of the same coin. Most maintenance and reliability engineers share a common goal which is to improve the performance of assets.

What they do to achieve this goal may be different, but in some organizations, the delineation of work is not always clear.

On the other end of the spectrum, the delineation may be too complete and result in siloed thinking and behavior.

There are several problems that arise from this separation of maintenance and reliability . For example, reliability engineers may make good decisions that can’t be practically executed by maintenance teams. Or, if decisions can be executed, there’s confusion about how tasks should be carried out. These problems are not the fault of any one team, but stem from a lack of alignment.

The question is how can an organization best achieve alignment between maintenance and reliability? The first step is establishing a clear definition of roles.

Defining the difference between maintenance and reliability

If you look at the position descriptions in your organization, you will see different responsibilities associated with your maintenance and reliability teams. The problem is that position descriptions very seldom inform one’s day to day work.

It is important that management and teams themselves are very clear on their responsibilities and the value they bring. One way to do this is by looking at the bigger picture and align roles to the functional requirements for asset management.

For most organizations, these functional requirements fall into four different categories. These are:

- Strategic decision making : This function is responsible for setting the strategy and making decisions such as how long to maintain an asset and how to care for it.

- Work management : This function involves implementing the strategy and specific responsibilities like planning and scheduling.

- Asset condition and monitoring : Once the strategy is put in place, there will need to be people and processes to monitor the work and provide feedback to decision makers.

- Root Cause Analysis (RCA) : RCA identifies the cause and effect relationships for a problem or event in order to generate solutions and prevent problems from recurring.

Once you’ve defined these functional requirements for your organization, you can identify the people and processes needed to carry out the work. There are some decisions that can be made on precedent. For example, strategic decision making tends to fall into the realm of reliability engineers.

However, it is also important to challenge some of these precedents. One of these is the frequent separation of duties based on the size of a problem. It is often assumed that small problems should be handled by maintenance teams while any bigger problems should be escalated to reliability teams. But who determines whether a problem is small or big, and on what basis do they make that decision?

More to the point, the size of a problem should not determine who fixes it. What’s important is who owns the process for resolution. For example, if an RCA is required, it should be completed by the team who owns the process.

This leads to a final point which is that you need more than a position description or organizational chart to create alignment. You need a process to drive the right activities and ensure optimal maintenance and reliability.

Complete Guide to Asset Strategy Management

This comprehensive guide offers everything you need to know to build, deploy, and sustain optimal asset reliability strategies across an entire asset base.

Read this next...

Major global oil & gas producer improves speed, quality, and cost of maintenance builds, reliability and maintenance: better together or better off apart.

- Training Home

- Training Courses

- Public Training Calendar

- Our Customers

- A Baker Hughes Business

Maintenance and Reliability

Jul 19, 2014

1.04k likes | 2.16k Views

Maintenance and Reliability. 17. PowerPoint presentation to accompany Heizer and Render Operations Management, 10e Principles of Operations Management, 8e PowerPoint slides by Jeff Heyl Additional content from Gerry Cook. Outline.

Share Presentation

- overall system reliability figure

- product failure

- air conditioning

- lecture guide practice problems

- breakdown maintenance costs

- maintenance costs

Presentation Transcript

Maintenance and Reliability 17 PowerPoint presentation to accompany Heizer and Render Operations Management, 10e Principles of Operations Management, 8e PowerPoint slides by Jeff Heyl Additional content from Gerry Cook

Outline • The Strategic Importance of Maintenance and Reliability • Reliability • Improving Individual Components • Providing Redundancy • Maintenance • Implementing Preventive Maintenance • Total Productive Maintenance • Techniques for Enhancing Maintenance

Learning Objectives Describe how to improve system reliability Determine system reliability Determine mean time between failure (MTBF) Distinguish between preventive and breakdown maintenance Describe how to improve maintenance Compare preventive and breakdown maintenance costs

Orlando Utilities Commission • Maintenance of power generating plants • Every year each plant is taken off-line for 1-3 weeks maintenance • Every three years each plant is taken off-line for 6-8 weeks for complete overhaul and turbine inspection • Each overhaul has 1,800 tasks and requires 72,000 labor hours • OUC performs over 12,000 maintenance tasks each year • Every day a plant is down costs OUC $110,000 • Unexpected outages cost between $350,000 and $600,000 per day

Strategic Importance of Maintenance and Reliability • Failure has far reaching effects on a firm’s • Operation • Reputation • Profitability • Dissatisfied customers • Idle employees • Profits becoming losses • Reduced value of investment in plant and equipment

Maintenance and Reliability • Reliability is the probability that a machine will function properly for a specified time • Tactics to improve Reliability • Improving individual components • Providing redundancy • Maintenance: activities involved in keeping a system’s equipment in working order • Maintenance Tactics • Implementing or improving preventive maintenance • Increasing repair capability or speed

Reliability Improving individual components Rs= R1x R2x R3x … x Rn where R1 = reliability of component 1 R2 = reliability of component 2 and so on

100 – 80 – 60 – 40 – 20 – 0 – n = 1 n = 10 Reliability of the system (percent) n = 50 n = 100 n = 200 n = 400 n = 300 | | | | | | | | | 100 99 98 97 96 Average reliability of each component (percent) Overall System Reliability Figure 17.2

R1 R2 R3 Rs .90 .80 .99 Reliability Example Reliability of the process is Rs= R1 x R2x R3 = .90 x .80 x .99 = .713 or 71.3%

Number of failures Number of units tested FR(%) = x 100% FR(N) = Mean time between failures Number of failures Number of unit-hours of operating time 1 FR(N) MTBF = Product Failure Rate (FR) Basic unit of measure for reliability

FR(%) = (100%) = 10% 2 20 FR(N) = = .000106 failure/unit hr 2 20,000 - 1,200 1 .000106 MTBF = = 9,434 hrs Failure Rate Example 20 air conditioning units designed for use in NASA space shuttles operated for 1,000 hours One failed after 200 hours and one after 600 hours

Probability of first component working Probability of second component working Probability of needing second component + x (.8) + (.8) x (1 - .8) = .8 + .16 = .96 Providing Redundancy Provide backup components to increase reliability

R1 R2 R3 0.90 0.80 0.90 0.80 0.99 Redundancy Example A redundant process is installed to support the earlier example where Rs = .713 Reliability has increased from .713 to .94 = [.9 + .9(1 - .9)] x [.8 + .8(1 - .8)] x .99 = [.9 + (.9)(.1)] x [.8 + (.8)(.2)] x .99 = .99 x .96 x .99 = .94

Maintenance • Two types of maintenance • Preventive maintenance – routine inspection and servicing to keep facilities in good repair • Breakdown maintenance – emergency or priority repairs on failed equipment

Maintenance Costs • The traditional view attempted to balance preventive and breakdown maintenance costs • Typically this approach failed to consider the true total cost of breakdowns • Inventory • Employee morale • Schedule unreliability

Total costs Total costs Full cost of breakdowns Preventive maintenance costs Costs Costs Breakdown maintenance costs Preventive maintenance costs Maintenance commitment Maintenance commitment Optimal point (lowest cost maintenance policy) Optimal point (lowest cost maintenance policy) Maintenance Costs Traditional View Full Cost View

Maintenance Cost Example Should the firm contract for maintenance on their printers? Average cost of breakdown = $300

∑ Expected number of breakdowns Number of breakdowns Corresponding frequency = x Maintenance Cost Example Compute the expected number of breakdowns = (0)(.1) + (1)(.4) + (2)(.3) + (3)(.2) = 1.6 breakdowns per month

= x Expected breakdown cost Cost per breakdown Expected number of breakdowns Maintenance Cost Example Compute the expected breakdown cost per month with no preventive maintenance = (1.6)($300) = $480 per month

Preventive maintenance cost Cost of expected breakdowns if service contract signed = + Cost of service contract Maintenance Cost Example Compute the cost of preventive maintenance = (1 breakdown/month)($300) + $150/month = $450 per month Hire the service firm; it is less expensive

Total Productive Maintenance (TPM) • Designing machines that are reliable, easy to operate, and easy to maintain • Emphasizing total cost of ownership when purchasing machines, so that service and maintenance are included in the cost • Developing preventive maintenance plans that utilize the best practices of operators, maintenance departments, and depot service • Training for autonomous maintenance so operators maintain their own machines and partner with maintenance personnel

Problems With Breakdown Maintenance • “Run it till it breaks” • Might be ok for low criticality equipment or redundant systems • Could be disastrous for mission-critical plant machinery or equipment • Not permissible for systems that could imperil life or limb (like aircraft)

Problems With Preventive Maintenance • “Fix it whether or not it is broken” • Scheduled replacement or adjustment of parts/equipment with a well-established service life • Typical example – plant relamping • Sometimes misapplied • Replacing old but still good bearings • Over-tightening electrical lugs in switchgear

Another Maintenance Strategy • Predictive maintenance – Using advanced technology to monitor equipment and predict failures • Using technology to detect and predict imminent equipment failure • Visual inspection and/or scheduled measurements of vibration, temperature, oil and water quality • Measurements are compared to a “healthy” baseline • Equipment that is trending towards failure can be scheduled for repair

Maintenance Strategy Comparison

In-Class Problems from the Lecture Guide Practice Problems Problem 1: California Instruments, Inc., produces 3,000 computer chips per day. Three hundred are tested for a period of 500 operating hours each. During the test, six failed: two after 50 hours, two at 100 hours, one at 300 hours, and one at 400 hours. Find FR(%) and FR(N).

In-Class Problems from the Lecture Guide Practice Problems Problem 2: If 300 of these chips are used in building a mainframe computer, how many failures of the computer can be expected per month?

In-Class Problems from the Lecture Guide Practice Problems Problem 3: Find the reliability of this system:

In-Class Problems from the Lecture Guide Practice Problems • Problem 4: • Given the probabilities below, calculate the expected breakdown cost. • Assume a cost of $10 per breakdown.

- More by User

SNS Reliability and Maintenance Programs

SNS Reliability and Maintenance Programs. George Dodson Research Accelerator Division Spallation Neutron Source. Topics. Vision and Goals Enablers Performance Metrics Management Information Systems Continuous Improvement RAMI Modeling Maintenance Management

1k views • 61 slides

Reliability & Maintenance

Reliability & Maintenance. Paul C. Czarapata. Maintenance Time.

387 views • 18 slides

Reliability Centered Maintenance Analysis

Systems Reliability, Supportability and Availability Analysis. Reliability Centered Maintenance Analysis. Cost of Maintenance and Repair. Obtained from the RCM Guide, NASA September 2008. What is RCM?. The purpose of RCM

3.16k views • 73 slides

Reliability Centered Maintenance 101

Reliability Centered Maintenance 101. Bob Appleton. References. DoDI 4151.22, December 2, 2007 NAVAIR 00-25-403, 1 March 2003 SAE JA-1011, August 1999 SAE JA-1012, January 2002 Boeing (2010) Statistical Summary of Commercial Jet Airplane Accidents, Worldwide Operations 1959-2009 , Seattle

1.68k views • 37 slides

Reliability Centered Maintenance (RCM) Applied in Maximo

GoMaximo 2018. Reliability Centered Maintenance (RCM) Applied in Maximo. Power Generation Company of Trinidad & Tobago Ltd., By Ian Ramsingh. PowerGen. Total installed capacity of 1008 MW Three Locations - PEN 243 MW PTLS 765 MW POS - Retired. Maximo at PowerGen. Maximo History

777 views • 23 slides

Maintenance and Reliability. Ross L. Fink. Maintenance. All activities involved in keeping a system’s equipment in working order. Reliability. The probability that a machine part or product will function properly for a specified time under stated conditions.

676 views • 10 slides

Project Management. Maintenance and Reliability

Project Management. Maintenance and Reliability. 14 Aug 2001. Introduction. What – Project Management Where – Where the success or failure of a project will have major consequences for the company

697 views • 32 slides

Maintenance and Reliability. 17. PowerPoint presentation to accompany Heizer and Render Operations Management, 10e Principles of Operations Management, 8e PowerPoint slides by Jeff Heyl Additional content from Gerry Cook. Outline. Global Company Profile: Orlando Utilities Commission

1.53k views • 55 slides

RCM – Reliability Centred Maintenance

RCM – Reliability Centred Maintenance. Jørn Vatn NTNU [email protected]. What is RCM?. RCM is a method for maintenance planning developed in the sixties within the aircraft industry and later adapted to several other industries and military branches

1.35k views • 46 slides

Fundamentals of Reliability Centered Maintenance RCM

Fundamentals of Reliability Centered Maintenance RCM. Marc Banghart April 5, 2011. About Me. Lead Reliability Engineer, Wyle Laboratories Jacksonville FL Supporting several Reliability Information Analysis (RIAC) contracts Past/Current Projects include:

1.14k views • 34 slides

RELIABILITY CENTRED MAINTENANCE (RCM)

RELIABILITY CENTRED MAINTENANCE (RCM). Application within RCAF and Implementation in OmegaPS. Mike Martin. BRIEFING OUTLINE. Maintenance Environment within RCAF RCM Process (MSG-3) Principles of RCM Significant Item Selection Functional FMEA Level 1 & 2 Decision Logic

1.79k views • 38 slides

Reliability Centered Maintenance (RCM) Analysis

Systems Engineering Program. Department of Engineering Management, Information and Systems. EMIS 7305/5305 Systems Reliability, Supportability and Availability Analysis. Reliability Centered Maintenance (RCM) Analysis. Dr. Jerrell T. Stracener, SAE Fellow. Leadership in Engineering.

1.35k views • 16 slides

Analytical Reliability Centered Maintenance Airline Example

Analytical Reliability Centered Maintenance Airline Example. RCM Conference – Chattanooga, TN October 2002. Jahan Alamzad 1250 Aviation Avenue Suite 200M San Jose, CA 95110 Tel: 408-295-7730 Fax: 408-280-5700 Email: [email protected]. CA Advisors. Objectives.

408 views • 12 slides

Certified Maintenance & Reliability Professional questions

Want to pass Certified Maintenance & Reliability Professional in First Attempt? Certified Maintenance & Reliability Professional Past papers Real Paper Questions Available at Exams4sure.com Certified Maintenance & Reliability Professional Braindumps with 100% Accurate Answers. 100% Exam Passing Assurance With Money Back Guarantee. Get Complete File From http://www.exams4sure.com/SMRP/CMRP-practice-exam-dumps.html

1.4k views • 22 slides

What is reliability centered maintenance and why it is important?

Auto Repair Savannah GA is an appropriate place to get all insurance claims and repairs all in place. When the repairs are minor one can use the slide hammer and dent lifter.

92 views • 1 slides

What is the link between reliability and maintenance, please elaborate.

Assignment Solutions, Case study Answer sheets Project Report and Thesis contact [email protected] www.mbacasestudyanswers.com ARAVIND – 09901366442 – 09902787224

65 views • 5 slides

Reliability Centered Maintenance - 9 Principles of Modern Maintenance

Brief history of the development of Reliability Centered Maintenance and the 9 Principles of Modern Maintenance.

202 views • 15 slides

Enhancing efficiency and reliability Industrial maintenance services

In order to maintain the reliability and optimal efficiency of the industrial operations, the Industrial Maintenance Services have become extremely important. There are contractors and companies that offer this type of services to enhance the performance quality and productivity rate of the industrial operation]ions. One such company is Mun Siong Engineering, which is one of the leading construction and integrated maintenance solution providers in Singapore.

35 views • 3 slides

Wardrobe Lock Maintenance Tips How to Ensure Longevity and Reliability

When shopping for new locks or replacements, consider reliable brands like Yale, which offers an extensive range of wardrobe door locks suited for various security needs. For more information on Yale locks in India and to buy wardrobe door locks that guarantee longevity and reliability, visit our website.

6 views • 2 slides

IMAGES

VIDEO

COMMENTS

View Homework Help - Module 3.3 Presentation Assignment Maintenance and Reliability.pptx from ASCI 202 at Embry-Riddle Aeronautical University. Maintenance Challenge/Issue: HUMAN FACTOR By: Christian ... Nihal Omer Module 3.3 Maintenance and Reliability.pptx. Embry-Riddle Aeronautical University. ASCI 202. Aeronautics.

View 3.3 Presentation Assignment Maintenance and Reliability.pptx from ASCI 202 at Embry-Riddle Aeronautical University. Aviation Maintenance Challenges Maintenance and Reality Maintenance

View Luke Bronstrup ASCI 202 3.3 Presentation Assignment Maintenance and Reliability.pptx from ASCI 202 at Embry-Riddle Aeronautical University. Aviation Maintenance Presented by: Luke

Blog. April 18, 2024. Use Prezi Video for Zoom for more engaging meetings; April 16, 2024. Understanding 30-60-90 sales plans and incorporating them into a presentation

2. Management Consultant Fred Schenkelberg Carl S. Carlson Reliability Engineering & Management Consultant Senior Reliability Consultant FMS Reliability (408) 710-8248 [email protected] ReliaSoft Corporation [email protected] [email protected] 2014 RAMS - Tutorial 2A - Schenkelberg 2.

Quality and Reliability Engineering Quality Engineering covers the tools and techniques employed in manufacturing and service industries. In product manufacturing, these techniques help prevent mistakes or ... Preventative maintenance 5.5.4.3. Failure replacement 5.5.4.4. Condition-based maintenance 5.5.4.5. Group replacement 5.5.4.6 ...

Reliability Example Reliability of the process is R s = R 1 x R 2 x R 3 = .90 x .80 x .99 = .713 or 71.3% R s R 3 .99 R 2 .80 R 1 .90 15. Product Failure Rate (FR) Basic unit of measure for reliability FR ( % ) = x 100% Number of failures Number of units tested FR ( N ) = Number of failures Number of unit-hours of operating time Mean time ...

Maintenance encompasses asset, equipment, and system management to prevent failure and sustain operational continuity. Reliability is the outcome of effective maintenance, which gauges an asset's ability to function as intended for a specific period. Manaswini Rao. May 9, 2024. Maintenance comes into action when something breaks down, and you ...

3.3 Maintenance and Reliability (Powerpoint) ... For this assignment, conduct research to identify a current aviation maintenance challenge/issue. ... In your briefing, you will identify the maintenance issue and provide a maintenance strategy to correct the maintenance issue. Your presentation must include a minimum of five, but no more than ...

9 Principles from RCM to create an effective preventive maintenance program. Whether you are developing a new maintenance program. Or improving the maintenance program for an existing plant. All reliable maintenance programs should be based on the following Principles of Modern Maintenance: Principle #1: Accept Failures.

Get the latest version at www.lifetime-reliability.com - the maintenance and reliability growth experts Maintenance_Management_3Day_Content.docx 25 March 2009 Page 1 of 7 Course Content Maintenance Management for Reliability Training Course Day 1 Content Introduction to Equipment Reliability Concepts Disclaimer - slides do not replace ...

3.3 PRESENTATION ASSIGNMENT: MAINTENANCE AND RELIABILITY This Photo by Unknown Author is licensed under CC BY-SA MAINTENANC E Definition • Maintenance comprises carrying out a series of actions, such as repairs and upgrades, to ensure that the passage of time has no effect on the aircraft's performance.

View ASCI 202 3.3 Presentation Assignment.pptx from ASCI 202 at Embry-Riddle Aeronautical University. 3.3 Presentation Assignment: Maintenance and Reliability Dongsuk Lee Embry Riddle Aeronautical

Presentation on theme: "Maintenance and Reliability Decisions"— Presentation transcript: 1 Maintenance and Reliability Decisions 17 Maintenance and Reliability Decisions PowerPoint presentation to accompany Heizer and Render Operations Management, 10e, Global Edition Principles of Operations Management, 8e, Global Edition PowerPoint slides by Jeff Heyl Additional content from Gerry Cook ...

This paper assesses the influence of effective maintenance. and reliability practices for operations management. 1 Introduction. Operations management is a business aspect related to. managing the ...

When it comes to organizational structure, maintenance and reliability are better together. True alignment, however, requires a better understanding of each function and the value they bring. Maintenance and reliability are, in many ways, two sides of the same coin. Most maintenance and reliability engineers share a common goal which is to ...

· 3.3 Presentation Assignment: Maintenance and Reliability . For this activity, you will assume the role of an aviation maintenance manager. As the aviation maintenance manager, you are responsible for all maintenance actions and for maintaining aircraft in a serviceable condition. For this assignment, conduct research to identify a current ...

1.1 Introduction. This Plan describes the organization and responsibilities for the reliability, maintainability (and safety) (RAMS) engineering tasks that will be integrated into the design, development, production and in-service support activities for the Super system project. It also describes the RAMS tasks that will be undertaken.