Search This Blog

Lean simulations, huge list of free lean games.

Thank you. Very helpful. Do you know of anywhere to get free training powerpoints?

Hi Josh, Thanks for stopping by! I have collected a few training presentations in my list of helpful lean tools and downloads in the top right sidebar. One of the most comprehensive lists of presentations I found is here on Scribd. Good luck!

Great List. Thanks. I have a variation of the Ball Point Game, which I call the Ball Flow Game and use with Kanban-based teams: http://availagility.co.uk/ball-flow-game/ Karl

Thanks Karl. I'll update the Ball Point Game post with a link to your version. I like the excel tracking sheet!

Maan, Any one knows about RED and BLACK game?

thank you, very helpful, I'm looking for a lean simulation game for sales, do you have it? thanks Hector

Do you know of any games that simulates Waste Elimination?

Nice compilation. I'll definitely try those. Thanks

Hi I have seen a game that had 5 puzzels in the shape of squares. A group of 5 had to each put one puzzle together, no talking. To make it work, usually someone had to take their perfect square and pull it apart for the good of the team to each have a completed square. Anyone have that or other game to get people to think about total systems? Thank you.

Hi Very helpful, thank you

Hi, Do you know of any games that can be used to teach DMAIC in a group exercise? I am thinking more of a small mechanism that can be used to simulate problem solving, setting standard conditions etc. Thnx

Hi WT, I don't know of any that follow the DMAIC process strictly. But the Gummy Bear DOE or something like it may work well for six sigma. You can vary the parameters and get different results.

Have a look at the 5S Numbers Game variant - 5salphabetgame.blogspot.com Online Version to use - Send your feedback on the blog.

Hi everyone, Does anyone know a game for TPM training? Thak you very much!

I haven't been able to find one for TPM unfortunately. If you find anything, be sure to let us know.

Really interesting and useful. Thank you I am looking for a "why-to-measure" game to be used in a Performance Management/KPIs/Improvement training session. Does anyone know a game on this subject? Thank you in advance

Interesting idea for a game or simulation. I'm sure you could add a KPI measurement aspect to many of these games and get to where you want to be. Not sure how much of a game it would be..

Lean friends, I am rolling out training for my team on Kaizen and an A3 Storyboard. I am looking for short (fun) videos that emphasize these two topics or even a short activity. Not sure why I am not finding anything that will work. Would appreciate any advice or wisdom on either of these subjects. Thanks, John [email protected]

Thanks for checking out the site, John. There are a bunch of activities on this page, which I'm sure you've looked through. For a fun video, you could try Lean Gone Lego!

Have you ever heard of a game that to show impact on customer satisfaction by a method of a team following a simple recipe by making a flavored beverage and substituting salt for sugar in order to see who checks the ingredients they are given and who uses them without checking?

I haven't heard of that one, but in the book "101 Games for Trainers" there is a game mentioned where you dissolve sugar in a beaker, salt in a different beaker (hard to dissolve, must shake it) and put a marble in a beaker (doesn't dissolve). This one is used to demonstrate the differences in conflict resolution. Some conflicts are easy to fix, others are harder and some are just not possible to find a resolution.

Hi Martin, Really interesting and useful. Thank you! The link for the Frog Factory does not work any more. Do you have more information (instructions) for this game?? H

Hello Martin Thank you for sharing all this interesting information about Lean Do you know if there is any short game (less than 30 min) that I can play with 3 people? Regards, Jorge

Hi Jorge, The Penny Game is probably the shortest game and can be easily played with only three people. It's a simple demonstration of batch vs single piece flow. Also, the 5S Numbers Game can be played with very few people, to show the benefits of 5S.

What is the best game to play if conducing a session on Kaizen? Looking to lighten it up with some videos and games. We are not in a production/factory environment, but a shared services team. Thank you!!

Thanks for the info. Do you know of any games (~30 min) that teach lean setup specifically?

A new version of 5S Game : http://leantools.info/5sgame/

I am looking for activities to do with remote employees. I'd love to do the spaghetti tower for PDCA but everyone is remote. What is another option for PDCA activities? Thanks, Tara

Hi Tara, most of these games require physically being in the same space. Standard Pig would work pretty well remotely, but it doesn't really highlight PDCA. It's more focused on standardized work, but you may be able to run it multiple times with improvement suggestions for PDCA. The 5S numbers game is also paper-based and can be done individually. But again, you would have to tailor it to focus on the PDCA improvement cycle, as it applies to 5S.

Post a Comment

Popular posts.

5S Numbers Game

Lean Lego Game - 4 Rounds to Successful Lean Training

Monday, May 18, 2020

- Five Lean Games Every Company Can Benefit From

No comments:

Post a comment.

Search A Lean Journey

Twitter updates.

- Facebook Updates

- Advertising

Subscribe Now

Get new posts by email:

A Lean Journey LinkedIn Group

Recent comments, search this blog.

Top 10 Posts

- Celebrating my 500th Blog Post

- Visual Management Board

- Guest Post: Reduce, Reuse, Recycle...

- What Do We Mean By True North?

- The Six-Step Problem-Solving Process

- 10 Characteristics of a Good Measure and 7 Pitfalls to Avoid

- DOWNTIME and the Eight Wastes

- The 8 Common Wastes in an Office That Cause Downtime

- Lean Leadership: Lessons from Abe Lincoln

Blog Archive

- ► July (1)

- ► June (12)

- ► May (14)

- ► April (13)

- ► March (13)

- ► February (12)

- ► January (14)

- ► December (11)

- ► November (13)

- ► October (12)

- ► September (13)

- ► August (13)

- ► July (8)

- ► June (13)

- ► April (12)

- ► February (13)

- ► January (13)

- ► December (12)

- ► October (13)

- ► August (14)

- ► July (13)

- ► May (13)

- ► August (10)

- ► March (14)

- ► July (14)

- Lean Quote: Three Key Goals of People at Work

- Lean Roundup #132 – May 2020

- Memorial Day – Honor. Remember. Never Forget.

- Lean Quote: Live a Meaningful Life

- Maintaining Productivity and Company Culture in a ...

- Lean Quote: The First Job of Any Leader is to Insp...

- Lean Tips Edition #154 (#2521 - 2535)

- The Five Types of People to Surround Yourself with...

- Lean Quote: Patience is to Be Calm No Matter What ...

- Seven Ways to Unlock Your Inner Leadership Skills

- 6 Ways to Influence Without Authority

- Lean Quote: Let Go Of Yesterday

- ► December (10)

- ► April (9)

- ► December (13)

- ► October (14)

- ► September (12)

- ► May (12)

- ► January (12)

- ► October (15)

- ► December (14)

- ► November (12)

- ► January (15)

- ► August (17)

- ► July (19)

- ► June (16)

- ► May (19)

- ► April (18)

- ► March (17)

- ► February (16)

- ► January (18)

- ► December (19)

- ► November (18)

- ► October (20)

- ► September (18)

- ► August (22)

- ► July (23)

- ► June (21)

- ► April (17)

- ► February (18)

- ► January (20)

- ► December (18)

- ► November (19)

- ► October (17)

- ► September (22)

- ► July (20)

- ► June (20)

- ► May (21)

- ► April (19)

- ► March (20)

- ► February (17)

- ► January (17)

- ► December (20)

- ► November (15)

- ► August (18)

- ► July (17)

- ► April (14)

- ► November (17)

- ► July (15)

- ► June (9)

- ► May (5)

- A Lean Journey (81)

- A Year Ago (8)

- ASQ's Influential Voices (40)

- Book Review (64)

- Change Management (53)

- Communication (13)

- Conference (10)

- Culture (38)

- Customer Focus (2)

- Daily Management (1)

- Development/Training (13)

- Empowerment (19)

- Engagement (37)

- Exercises/Games (8)

- Facilitation (2)

- Feedback (3)

- Guest Post (167)

- In the News (70)

- Innovation (2)

- L.A.M.E. (5)

- Leadership (222)

- Lean and Green (12)

- Lean Basics (109)

- Lean Definition (24)

- Lean Fun (10)

- Lean in Practice (55)

- Lean Management (152)

- Lean Office (14)

- Lean Products (4)

- Lean Quote (730)

- Lean Resources (44)

- Lean Roundup (200)

- Lean Thinking (5)

- Lean Tips (235)

- Meet-up (31)

- Podcast (5)

- Problem Solving (21)

- Product Review (2)

- Project Management (6)

- Quality (50)

- Respect For People (57)

- Sharing Best Practices (129)

- Soft Skills (3)

- Strategy (6)

- Supply Chain (1)

- Talking Lean (1)

- Teamwork (42)

- Visual Factory (31)

- Webinar (23)

Lean Blogs I Like

- 2 Lean Principles

- 5S Supply Blog

- Avoiding The Corporate Death Spiral

- Be More Careful!

- Curious Cat

- Daily Kaizen

- Evolving Excellence

- Gemba Panta Rei

- Gemba Tales

- Got Boondoggle?

- Gotta Go Lean Blog

- Improve With Me

- Jamie Flinchbaugh

- Kaizen Notebook

- Lean Builder

- Lean Communications

- Lean For Everyone

- Lean Healthcare Exchange

- Lean Homebuilding

- Lean Insider

- Lean Is Good

- Lean Leadership

- Lean Pathways

- Lean Printing

- Lean Reflections

- Lean Simulations

- Lean Six Sigma Academy

- LeanCor Blog

- Learn Lean Manufacturing

- Learning About Lean

- Old Lean Dude Blog

- The A3 Post

- The Lean Edge

- The Lean Library

- The Lean Logistics Blog

- The Lean Thinker

- The Lean Way Consulting

- TimeBack Blog

- To The Gemba

- Training Within Industry

- Visual Management Blog

Other Sites I like

- AME's Target Magazine

- AnythingLean.com

- Art of Lean

- Bosch Rexroth Lean Production

- CIRAS - Theory of Constraints

- Chasing The Rabbit

- Corporate Event Management

- Creative Safety Supply

- Creative Safety Supply 5S Resource Page

- Fuss & O'Neill SPL

- Gemba Academy

- Grassroots Innovation

- IndustryWeek

- Lean Enterprise Institute

- Leanovations

- Learn More McGraw-Hill

- MEP University

- Manufacturers BlogNotions

- Manufacturing Business Technology

- Manufacturing Pulse

- Modern Machine Shop

- Running A Hospital

- Superfactory

- The 5S Store

- Unclutterer

- Visual Workplace

- Xtreme Lean Consulting

- catalyst for change

- freeleansite.com

wibiya widget

A lean journey blog - copyright © 2009-2024 tim mcmahon - all rights reserved.

The 3 best Lean games every company should learn to play

Monday 19 Jul 2021 | Games | 0 comments

Xunzi may have been the first experiential teacher…

“ Tell me, and I will forget. Show me, and I may remember. Involve me, and I will understand. ” – Xunzi (Xun Kuang), a Confucian philosopher who lived in the third century B.C.E.*

At St Andrews Lean Consulting we agree with Confucius – getting involved is the best way to learn. This is why Lean games are such a valuable tool for organisations on their Lean journeys.

The 5S Numbers game

5S is an approach for workplace organisation; it drives workplace efficiency and productivity improvement. 5S is a series of steps that can be used in the Implementation Stage of the SALC 8 Step process improvement Model, but is also an everyday “Good Practice” on which organisations can build strong foundations for Continuous Improvement.

Translated from the Japanese words seiri , seiton , seiso , seiketsu , and shitsuke , the 5S’s are Sort, Straighten, Shine, Standardise, and Sustain. But don’t mistake 5S for Housekeeping or Spring Cleaning. “Workplace organisation” may mislead one into believing 5S is a tool for optimisation of office cleanliness, or just a general tidy up of the workspace. It is much more than that, it refers to the way each element in the workplace is managed and organised.

How do we play the 5S numbers game?

The aim of the game is to demonstrate how valuable 5S can be in your organisation when utilised properly. Each sheet of paper represents a workplace

Step 1 : The first sheet shows a pre-5S workplace. During a single shift (20 seconds) the task is to strike out numbers 1 to 50 in the correct sequence. 1, 2, 3, … Record everyone’s score, they highest number they struck out. Lowest score becomes the score for whole team.

Step 2 : The first ‘S’, Sort. We know the task is to strike out numbers 1 to 50, therefore numbers 51 and above are not required, and so they can be taken out. Repeat the task and record the score.

Step 3 : Straighten, the second ‘S’. We have installed the grid system. Now we can look through the numbers more effectively as they are in smaller more organised groups. We have provided a home for everything. Repeat the task and record the score.

Step 4 : The third ‘S’, Shine. Is everything fit for purpose? We have cleaned up all the numbers, they are all clearly visible. Repeat the task and record the score.

Step 5 : Now the fourth ‘S’, Standardise. Here we define the standard we want to work to. We know the task requires us to strike through 1 to 50 in order, so let’s reorganise to make the completion of the task as efficient as possible. Repeat the task and record the score. By this stage everyone should be able to complete the task within the shift, with a team score of 50.

Step 6 : Let’s start again, back to our pre-5S workplace. But this time, we’re looking to see what numbers are missing! Can the team find the missing numbers within 20 seconds?

Step 7 : If our workplace had been 5S’d this is what it would look like, and it would be easy to see which numbers were missing. To reinforce the point, can the team find the missing numbers within 20 seconds? Off course they can.

Step 8 : The final ‘S’, Sustain. This step is all about custom and practice, keeping the right things in the right place . 5S has become a good habit, the way we do things around here. It’s so much easier now to find what you need and to identify problems.

Skills, tools, and techniques the 5S Game may help you with include 5S (that’s a surprise!), implementing a new process, and Daily Lean.

Find out more about 5S .

The Standard Fish game

Our next game will show up the Picasso’s and the van Gogh’s in your work force.

What is The Standard Fish game all about?

Standardised work is arguably one of the most powerful but under-utilised lean tools. By documenting the best-current practice you ensure that every client or customer receives the same offering, reduction in variation, easier training for new team members and you set a baseline for continuous improvement. As the standard improves, the new standard becomes the baseline for further improvements and so on.

So, the Standard Fish Game is all about documenting the process for drawing a fish, which matches the service receivers’ requirements.

How do we play The Standard Fish game?

Step 1 : Ask your team to draw a fish on a sheet of A4. As mentioned before, you will see a vast array of artistic creations. The variation in fish design stems from a lack of instructions on how to draw a fish. This is not a documented process. None of fish are draw to a customer specification. Voice of Customer is important concept in any business process.

Step 2 : Give your team a sheet of A4 with 3×3 grid on it. Read out the following instructions

- Draw a letter X in the centre box in the left column. The X should fill the box touching the intersections

- Draw an upward arc from the top left intersection to the top right intersection

- Draw a downward arc from the bottom left intersection to the bottom right intersection

- Draw an arc from the top right intersection to the bottom right intersection

- Draw a circle for the eye in the middle of the right grid line

- Draw an upside down V for a fin in the middle of the curve in the top central box

- Draw two V’s, for fins, spaced evenly apart on the lower central curve

- Draw a curve from the top left point of the X to the bottom left point of the X to form the tail

- Draw an arc for the mouth starting at the bottom right intersection. Must be a happy fish!!

- And finally draw four circles for bubbles – two in the middle of the central right box and two in the top right box

Step 3 : Compare the 2 sets of drawings. The second set of drawing will be much more similar. The waste in the process has been eliminated, and the standard of work will be much higher.

Step 4 : These sets of instructions may need review. They may not be as comprehensive as first thought. Drawing fish may have developed since the first time your company drew a fish. The customer may now be asking for a shark.

Skills, tools and techniques the Standard Fish Game may help you with include Best Practice, Communication, Standard Work and Variation Reduction.

The Ball game

Having trouble keeping all your balls in the air? There’s a game for that…

What is The Ball Game all about?

The Ball Game is all about eliminating waste in your company activities and continuously improving processes.

In 2 groups, of no less than 5, all you need to do is pass 3 balls between the 5 of you in the same pattern. Sound simple enough? How quick do you think you can do it? Less than a minute? Not bad. Not as good as 0.5 seconds though. I can hear you saying “0.5 seconds? No, surely not! It takes me 0.3 seconds to blink!!” Let’s look at the process.

This game could be a simulation of any process. From onboarding staff and clients to the Accounts Payable Process. The Ball represents the task and the movement represents how the responsibility passes from team member to team member. We ran this game for a group of clients in 2019. At the beginning of the process the 5 team members were sat around a circular table and they threw the ball to each person. It took them 56 seconds to complete the task. The only rules were:

- The ball has to have air

- Everybody must touch the ball

- It must follow the same pattern each time

- Start Point is the End Point

One set of our clients re-examined their process and decided that crossing the table wasted too much time. They lined up and tried again. This process of Plan Do Check Act, allowed them to trial and error different approaches. This method took 21 seconds. After a few more tries they got it down to 0.5 seconds. Now you’re thinking “this is not possible, tell us how!!” One member of the team stood in the middle of the group, the other members in a circle round the outside. The member in the middle held the three balls in one hand, the members on the outside held out their opposite hands. Touching each member’s hand with the three balls, the middle member span round in a circle. Phenomenal.

Questions to consider:

- Imagine cutting all the waste out of your process so that it takes 1/112 of the original time.

- Which processes in your business could be Leaned?

- Is there a lot of waste in a process because “that’s the way its always been done”?

Skills, tools and techniques the Ball Game may help you with include Communication, Continuous Improvement, Flow, PDCA, Teamwork and the Eight Wastes.

If you would like to find out more about how we can help, get in touch .

* There are many variations of this quote, and thank you to Lon Bailey for your clarification regarding attribution.

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

- Agile Strategy Lab

- Announcement

- Development

- Guest blogs

Recent Posts

- New website!

- What does Lean mean? What does Lean stand for? What’s it all about?

- ISO 18404: Should you adopt standardised Lean (and Six Sigma) certification?

- What are those Lean books behind you?

- Which process do I improve?

5s methodology collaborative problem solving communication communication skills continuous improvement covid-19 cultural change customer experience customer focus customer needs customer satisfaction customer service efficiency facilitation techniques higher education improvement increased efficiency kanban Lean lean games lean in higher education lean thinking lean training manufacturing pdca cycle problem solving process improvement productivity project management project planning rapid improvement event reduced costs RIE staff engagement teacher workload team building teamwork thinking value stream mapping visual management waste waste elimination waste reduction WIP work in progress workplace organization

Games as a way to coach and teach lean thinking

FEATURE – Simulations and games can be extremely beneficial, so long as we use them to highlight and explain the underlying behaviors we must adopt if we are to successfully embrace lean... and not only the tools.

Words: Bruno Pešec, industrial engineer, lean practitioner and martial artist

From a theoretical standpoint, most lean principles and tools are relatively easy to understand. The challenge seems to appear with their practical application – which is why the only place to learn lean is the workplace, the very environment in which the work is done.

Short lectures or workshops before moving to the gemba are common, and can greatly enhance the learning. Because this sort of classroom training tends to be perceived as boring, however, one could be excused for seeing it as a one-sided form of education (the teacher explains different concepts and the audience is either writing notes or battling sleep).

Indeed, as lean coaches, we must always look for new ways to improve the learning experience, and I have personally found that using games and simulations works quite well.

TEACHING GAMIFIED

Teaching lean thinking this way is a commonly recognized approach in our community. There are numerous lean games out there – free or requiring payment, physical or online. (Martin Boersema provides a 50-strong list of lean games and simulations here .) There is even an academic term for meshing education with gameplay: “gamification”, which Huotari and Hamari ( 2012 ) define as a process of enhancing a service with affordances for gameful experiences in order to support user’s overall value creation . Ramos, Lopes and Avila ( 2013 ) say that using games as teaching tools benefits the teaching-learning process , especially when it comes to:

- introducing difficult concepts;

- developing problem-solving and decision-making skills;

- promoting an active participation of the student;

- increased interest among students;

- developing each student’s talents, which welcomes students at different learning levels; and

- helping the teacher identify each student’s difficulties.

What I also found is that they are a great way to kick-start one’s journey to understanding and accepting new principles. In Teaching Lean Manufacturing With Simulations and Games ( 2010 ), the authors explore different lean games and simulations, and how they help develop various lean skills, behaviours and traits. More importantly, they discuss the importance of the role of the facilitator: in other words, these games and simulations are most effective when run by a facilitator who is knowledgeable and experienced about lean thinking and practice and possesses good communication and storytelling skills.

UNDERSTANDING LEAN STARTUP WITH A GAME

Lean Startup is a methodology for developing businesses and products, aiming to shorten product development cycles by adopting a combination of hypothesis-driven experimentation, iterative product releases, and validated learning. It seeks to eliminate wasteful practices and increase value-creating practices during the product development phase by focusing on what customers truly want.

Simen Fure Jørgensen, the former CEO of a Norwegian software development consultancy, has been using the getKanban board game to teach people kanban in knowledge environments, with great success. When he started teaching Lean Startup, he quickly began to look for a game that would help him. Struggling to find one, he decided to create one. He called it Playing Lean .

What I like about Playing Lean is that the game, too, was developed using Lean Startup principles. After validating the problem, Jørgensen was joined by Tore Rasmussen, an entrepreneur who was at that time looking for a research project for his master’s thesis. Together, they ran a lot of experiments, taking the game through numerous iterations before they had the product they knew customers truly wanted.

To date, I’ve used Playing Lean in more than 30 workshops, with over 500 people playing it. I found the game really helps convey fundamental lean principles, and it really works as a team-building tool.

Game mechanics are simple, fun and fast to grasp (one turn, approximately 10 minutes). Players are divided into teams and assume the role of a fictional startup. Teams then compete in the same market and for the same customers, with the goal of being the first to reach scale (e.g. more than 100,000 customers in the Social Media scenario).

The game is divided in two phases: planning and execution. In the planning phase teams assign their employees one of the following tasks: develop a product, train, run an experiment or sell. Discussions are normally lively during this phase – how do we proceed? What strategy do we want to pursue? Do we want to satisfy all the customers or look for the quickest path to “victory”? How do we handle competition? Do we want to make the best product or do we want to invest time to find out what the customers want? These questions, and the discussions they generate, are very valuable for the learning experience of the attendees (once again, the role of the facilitator is crucial). In the execution phase, teams will find out what the outcome of their actions is. In case of product development and staff training, there are no uncertainties. When it comes to experimentation, there is an element of randomness as the experiment might fail or succeed, with varying results. A failed sale has long lasting consequence, namely that customer will not give another go at the failing team’s product.

The only way for teams to advance in the game is by selling their product successfully. Following the four stages of Lean Startup, all teams begin at the Business Modelling stage, working their way through Problem/Solution fit and Product/Market fit stages, before finally reaching Scaling stage. There is only one winner – the team that reaches scaling stage first.

The game is designed to engage and entertain participants, opening them up to new thinking paradigms. Due to the short attention span our world is characterized by, learning and playing must be carefully balanced. When I play this game, my way of achieving this – and ensuring people learn – is using Experiment Cards and Retrospection sessions.

Each experiment card introduces one of the Lean Startup principles, tools or methods. It has a title, a short description and a “result” (how much you, as a participant in the game, have learned about the customer). To maximize learning, the facilitator might want to tell a story related to the card, sharing his experience and explaining real-life examples of how the tool or method can be applied.

In my experience, another fundamental moment of learning occurs when the game is over, by means of a retrospection session (either guided or not). Giving the teams the time to reflect on why their team won or lost, on their overall strategy, on their fictional company’s need to pivot and on whether they were affected by technical debt typically leads to several a-ha moments. And because of the emotional involvement that games facilitate, the learning tends to last.

NO SILVER BULLET

Teaching tools is easy. Changing behaviour is anything but.

As a coach, I teach tools as an alibi – my real focus is on creating behaviors that enable sustainable lean transformations. For example, when I hold a workshop with Playing Lean, participants are usually focused on learning various tools like lean canvas, minimum viable product, customer interviews, and so on. These are important, but understanding and developing the underlying behaviors and motivation is way more critical to sustaining change. At that’s what we should use games and simulations for.

With proper facilitation, they can create a “microcosm”, a bubble in which participants can safely try different approaches. It liberates them from the burden of failure in their business and empowers them to think and act differently.

There is no doubt this can be a highly effective way of teaching lean thinking, but that is not to say that one should expect to succeed in developing people by only training teams of experts through playing games. Game-based teaching is mainly a resource for coaches and cannot – and should not – replace the knowledge that people develop by practicing lean at the gemba and learning by doing. In this sense, games and simulations should serve as a bridge between theory and the real-life application of lean principles in the workplace.

FEATURE – How reading lean books empowered people and transformed the managerial culture at an industrial bakery in the Western Cape Winelands in South Africa.

CASE STUDY – This Italian manufacturer has found in lean a way to ensure business continuity and provide support to a distraught workforce in the midst of the coronavirus outbreak.

FEATURE – Using the Japanese tradition of daruma dolls as an example, the author explains how to turn continuous improvement into concrete challenges – and, from that, real competitive advantage.

CASE STUDY – Thousands of kaizens, a relentless focus on learning and the determination to continuously improve have made of this Norwegian company something of a lean fairytale.

Subscribe for our newsletter and get early access to all exclusive Planet Lean articles.

How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

Elisabeth Swan is the co-author of “The Problem-Solver’s Toolkit” and co-host of “The Just-in-Time Cafe Podcast.” She’s been a process improvement consultant, speaker, and innovator for over 30 years. She’s the Chief Learning Experience Officer for GoLeanSixSigma.com, a former cast member of ImprovBoston, and – if asked – may still be able to ride a unicycle.

Surgeon Atul Gawande made headlines when he told the world that a simple checklist could drastically reduce unnecessary deaths in The Checklist Manifesto .

Yet, checklists conjure images of forklift drivers on loading docks with clipboards counting boxes. How could they transform healthcare?

“ He has… produced a 90-second checklist which reduced deaths and complications by more than one-third in eight hospitals around the world – at virtually no cost and for almost any operation. ” – James Clarke, reviewing The Checklist Manifesto, Ulster Med J. 2011 Jan; 80(1): 54.

Aviation was transformed decades earlier when management and engineers at Boeing Corporation created the pre-flight checklist after the 1935 crash of the prototype Boeing B-17 at Wright Field in Dayton, Ohio. Checklists have become so essential to the airline industry that most crashes can be traced to the misuse or failure to complete a checklist.

A New York Times reviewer noted, “no matter how expert you may be, well-designed checklists can improve outcomes”. Since the purpose of process improvement is improving outcomes, Lean Six Sigma and checklists are natural companions.

To prove that, this Process Street blog post will show the relationship between checklists and lean six sigma, and provide you with a free DMAIC Improvement Project Tollgate Checklist that you can use right now.

Use the links below to jump to that section of the post:

Lean Six Sigma and the role of problem-solving

Lean six sigma & the checklist, introduction phase, define phase, measure phase, analyze phase, improve phase, control phase, checklists and lean six sigma, use process street to reduce error.

Or, if you just want the checklist, check it out below!

Let’s get started.

For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.

It’s a customer-focused, 5-step problem-solving model that engages entire workforces to constantly seek a better way of doing things.

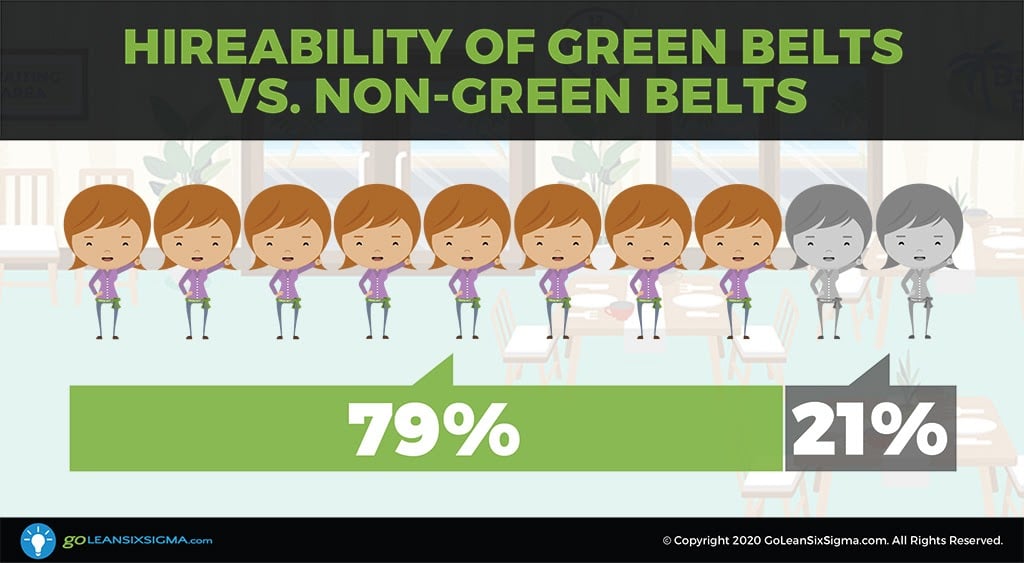

Proof of Lean Six Sigma’s influence is evident in today’s hiring practices. A poll by GoLeanSixSigma highlights that hiring managers prefer a person who is “ Green Belt Certified ” – having substantial Lean Six Sigma skills – by an almost 80% margin. In an interview with the former head of Twitter, problem-solving emerged as the top skill sought by today’s most influential hiring managers.

In other words, problem-solving (especially via Lean Six Sigma) is an absolutely vital skill.

If problem-solving is a must-have skill and checklists are key to good outcomes, then combining the two makes sense.

DMAIC – Define, Measure, Analyze, Improve & Control – is the 5-Step model for Lean Six Sigma and there’s a set of required tollgates at the end of each phase. These tollgates outline what has to be done in order to move the problem-solving process forward.

Using the tollgates as an outline, we created a dynamic Process Street template that you can use for free and run checklists from to track your progress!

Before you can start solving problems, you need a problem to solve.

Picking a process issue – and finding someone in leadership to support you – are two required tasks in this first tollgate. Scoping the project is important (bigger than a “just-do-it” and smaller than “solving world hunger”) but even more critical is finding a Sponsor.

Finding a Sponsor

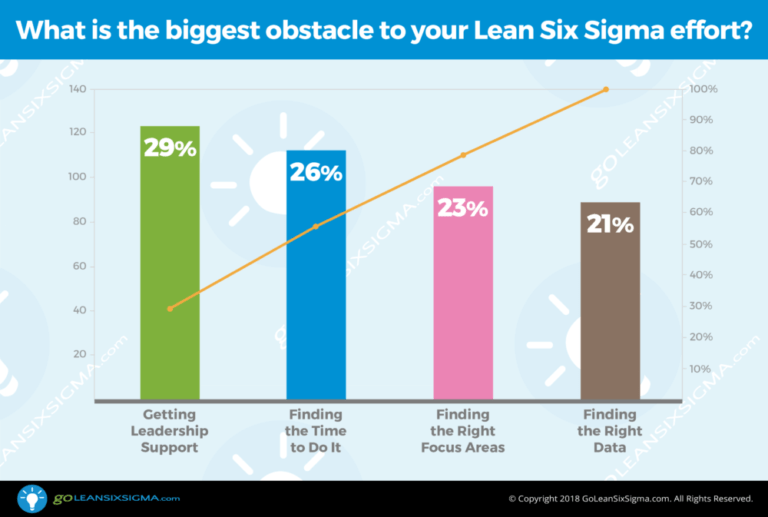

In a poll asking Lean Six Sigma practitioners what they considered the biggest obstacle to process improvement success, “Getting Leadership Support” accounted for almost a third.

When we coach team leads who tell us they can’t find someone to back their project, we let them know, “No Sponsor, no project”. If nobody in charge has any skin in the game, there’s no point in attempting the process fix. Find a different project that leadership supports.

One thing that helps when searching for leadership backing is being able to explain what Lean Six Sigma is and why it makes a difference. Since the checklist template is dynamic we inserted a video in the Define Phase within the checklist item, “Enlist a Project Champion/Sponsor who will support you and the project”. The team lead can share the video with managers or directors who they consider Sponsor candidates.

There’s also a Project Selection Guide Template embedded in the checklist so users can take a project idea and put it through a few screening questions. Is it a repeating problem? Is there a way to measure it? The checklist serves as a reminder, a source of templates, supporting videos and other just-in-time guidance.

The next set of tollgate tasks cover the Define Phase of DMAIC. This is where problem-solvers clarify the problem, the process impacted and customers of the process.

There is a journey of discovery during this phase as everyone agrees on the issue to solve. One of the big challenges is the tendency of ambitious team leads—or equally ambitious Sponsors—to try to “shoot the moon.”

Shooting the moon

They might want to reduce cycle time, reduce defects , improve margins, and increase customer satisfaction all by next Tuesday. But a project that focuses on everything accomplishes nothing. It’s okay to measure the cost reduction that results from reducing defects. But pick one of those to be the goal. Success is more possible if you focus on one goal at a time .

It takes practice and discipline to develop a manageable goal statement. Another moon shot is aiming for perfection out of the starting gate. When we see a goal statement that claims the team will, “reduce defects from 25% to 0%” then we know there is a sizable risk of failure and disappointment.

That’s why the Define Phase of the checklist includes a Goal Builder Template along with a blog providing tips on how to create well-crafted goal statements.

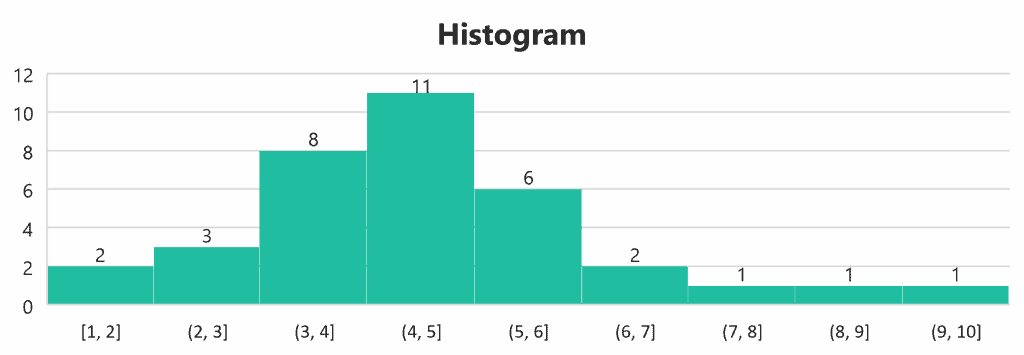

The primary focus of the Measure Phase is to baseline the process. If you’re trying to reduce defects, you need to know how you’re doing at that now. What’s your track record? You need to know the baseline of the process in order to measure whether or not you made a difference with your improvement when you get to the Improve Phase.

You need to know the gap, so you can close the gap.

The data’s in the system, somewhere…

One of the issues we run into in this phase is problem solvers assuming that data is sitting in a system somewhere waiting to be accessed. If they simply run a report, they’ll have the baseline. Check that off the list. But that rarely goes according to plan.

Maybe there’s system data, but was it entered with care? Is it reliable? We’ve seen teams struggle to use data that didn’t make sense. They could access cycle time data, but it didn’t take into account that the workday ended at 5:00. I had another team looking at why healthcare invoices had to be manually adjusted. They looked up the defect codes and the biggest category was “Other”. System data existed, but it was useless.

Most of the time, it helps to collect some data manually. In order to think through your approach, you need a Data Collection Plan. That involves listing the data you want and considering things like stratification factors—the “who, what, when, where” of data. If you’re looking at defects, should you collect data on defects by product? Defects by the fields on a form? Defects by customer type?

Within the task: “Develop a Data Collection Plan with Operational Definitions and create Check Sheets as Needed”, we’ve embedded a template (The Data Collection Plan) and a video to guide the process.

You’ll learn a lot by collecting the data firsthand, so if the perfect data set is not magically sitting in the system, it helps to have a plan.

Analyze is the crux of the DMAIC method. This is where learners drill down and discover the root cause of the process problem they’ve been chasing. Once you do that, you can solve the problem for good.

But if you have not determined the root cause then you might be solving a “symptom,” putting a bandaid on the problem or implementing a change based on a hunch. All of this means there’s a high likelihood the problem will remain and the efforts will have been in vain.

Finding the smoking gun

If you’ve always been told, “don’t bring me a problem, bring me a solution,” that’s an encouragement to jump right past this step into the fun of solutions. I’ve seen teams go with their assumptions regardless of what the data says or the process analysis reveals. I’ve seen Sponsors who tell teams what solutions they want to be implemented right from the get-go.

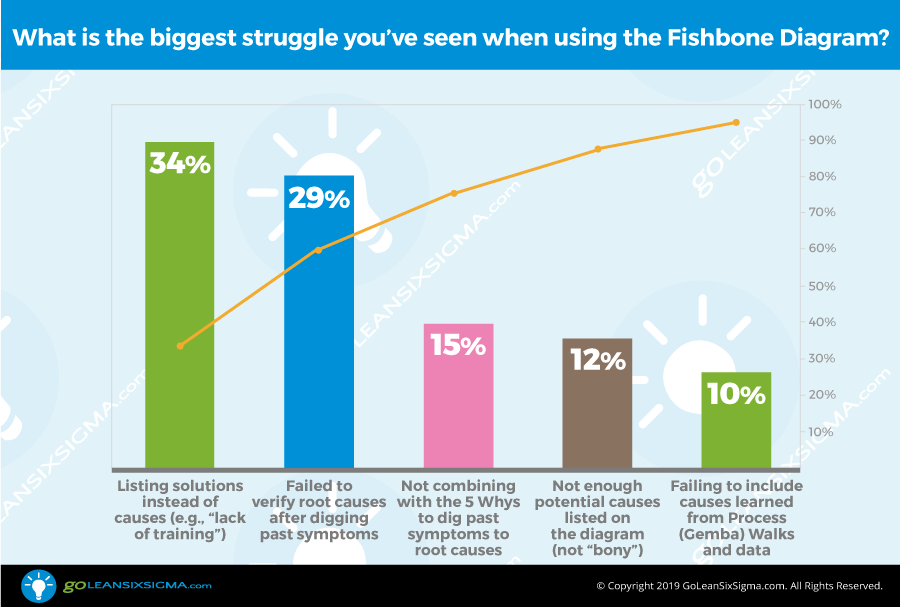

How do you stick with analysis long enough to find the smoking gun? The trick is to keep collecting the clues in the Cause & Effect Diagram , aka The “Fishbone Diagram”. It’s an aptly named tool, popularized by Dr. Ishikawa , which resembles a fish skeleton. Its construction allows teams to develop root cause theories around a problem as they build their knowledge of the process.

Each time they collect data, interview process participants on a Gemba Walk or map the process steps, they uncover potential reasons for defects. Making the most of the Fishbone Diagram is key but, during a poll, users reported where they fell short.

Solutions masquerading as problems

Over a third of respondents reported the issues of “listing solutions” on the Fishbone instead of causes. What we hear are phrases like, “the root cause is a lack of training”.

The problem with “lack of” anything is that it’s a sneaky way of putting a solution on the Fishbone.

The question is, “what is the training addressing?” Is it lack of user knowledge? If that’s the problem, could it be solved with helpful visuals, a simpler process? There are a lot of ways to address user knowledge before jumping to more employee training.

This is when you want to behave like the persistent detective – think Columbo, the classic 70’s TV icon. Every question helps you accumulate clues. People working through the process may have the answer without knowing it. The trick is to keep looking upstream until you find potential culprits. Dig past the symptoms.

To help with this phase, the checklist includes both a Fishbone Diagram Template as well as a video on how to get the most out of the Fishbone.

The Improve Phase is a long-anticipated step in the journey. It’s the step teams generally want to jump to from the start. Testing countermeasures, piloting solutions, watching the problem disappear, that’s the fun of process improvement. If you’ve done a proper job of Define, Measure, and Analyze, this phase falls nicely into place.

The ripple effect

The catch? Unintended consequences.

If you toss a stone into a lake you can see the ripples flow out from the center. The same principle holds true for process change. If you remove a step, change a form, skip an approval , will things fall apart? For that, we look to the Failure Modes & Effects Analysis or FMEA for short.

It’s a methodical way of assessing the potential for things to go wrong. It Involves deciding the potential severity and frequency of future problems and then mistake-proofing the process to prevent them. The technique originated at NASA since they couldn’t risk trial and error when sending men to the moon. By thinking through the risks of change they developed the kind of contingency plans you saw on display in movies like Apollo 13.

That’s why there’s an FMEA Template and a video on how to use it tucked into the main checklist from this post.

It’s okay to make changes. It’s simply key to think through the impact of those changes on other parts of the business.

Process Improvement can happen quickly and have a dramatic impact, but it’s critical to “stick the landing.” The Control Phase exists to see the improvement through to stability.

If teams move on and everyone takes their eyes off the ball, things may start to slip. What they need is the ability to continuously see the performance of the new process.

Sticking the landing

Have you ever tried to watch a game without a scoreboard? How would you know who was winning? Or how much time was left?

It’s the same with process work.

How does your team know how they’re doing? How do you stay aware of how the new process is performing?

By making the data visible.

Keeping an eye on Process Performance can be done with a single metric — you need to focus on one thing. If the goal was to reduce defects, then the single metric would be tracking the daily percentage of defects. A great way to measure success is with a Control Chart.

Control Charts are time charts. You might know them as Line Charts or Run Charts. They include a measure of variation so they are often referred to as “Run Charts that went to college”. They can be created in Excel , but they can also be drawn by hand.

Teams often set up whiteboards in the shared workspace to track things like defects. People can rotate responsibility for updating the chart. If people can see the measure and are responsible for it—they pay attention to it. What gets measured gets managed.

The Control Chart Template is embedded in the checklist for the Control Phase.

Process Improvement is a mainstay of Operational Excellence and checklists are simple but effective ways to make sure you get the outcomes you want. The following quote comes from the interim CEO/President of the Association for Manufacturing Excellence ( AME ).

“ I am a big fan of checklists for ensuring quality at the source. They serve an important purpose in reminding us of all that’s needed in a particular process or project. Without checklists, we risk missing or overlooking something by mistake. Checklists work best when ticking off items as they are completed, not en masse once the entire project is done. The key point is to use and follow them, not “pencil-whip” them from memory after the fact. While not foolproof, checklists can help us cover the details and result in more thorough, successful improvement efforts. ” – Jerry Wright , President, AME

Checklists have transformed healthcare, aviation, and countless other industries. Run this Process Street DMAIC Tollgate Checklist and make sure your next improvement effort gets great results.

Process Street is a powerful piece of workflow software that lets you crush the human error in your organization.

By creating process templates (like the free DMAIC checklist in this post) you can give your whole team a central location for them to see what they have to do, and how exactly they should do it.

No more confusion, no more errors.

Take advantage of our powerful feature set to create superpowered checklists, including:

- Form fields

- Conditional logic

- Variable user permission levels

- Exporting and printing templates

- And much, much more!

Check out our intro webinar to see the app in action!

Stop leaving the success of your processes up to chance. Get started with a free trial of Process Street today!

How do you manage quality control in your business? Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Ben Mulholland

Ben Mulholland is an Editor at Process Street , and winds down with a casual article or two on Mulholland Writing . Find him on Twitter here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Culture , Lean Training , Lean Wiki , Tools

A Deep Dive into the A3 Problem-Solving Approach

- 11 mins to read

- June 20, 2023

- By Reagan Pannell

In today’s fast-paced and fiercely competitive business world, organisations must find ways to continuously adapt, evolve, and excel. Amidst the myriad methods and techniques for achieving improvements and driving continuous improvement, few have proven as profound and transformative as Toyota’s A3 problem-solving approach.

A significant driving force behind the company’s rise to global prominence, the A3 process fosters a culture where problems are embraced as opportunities for growth and learning. In this article, we’ll explore the origins and underlying principles of the A3 approach and uncover the secrets to its success in unlocking the power of improvements.

Understanding the A3 Approach

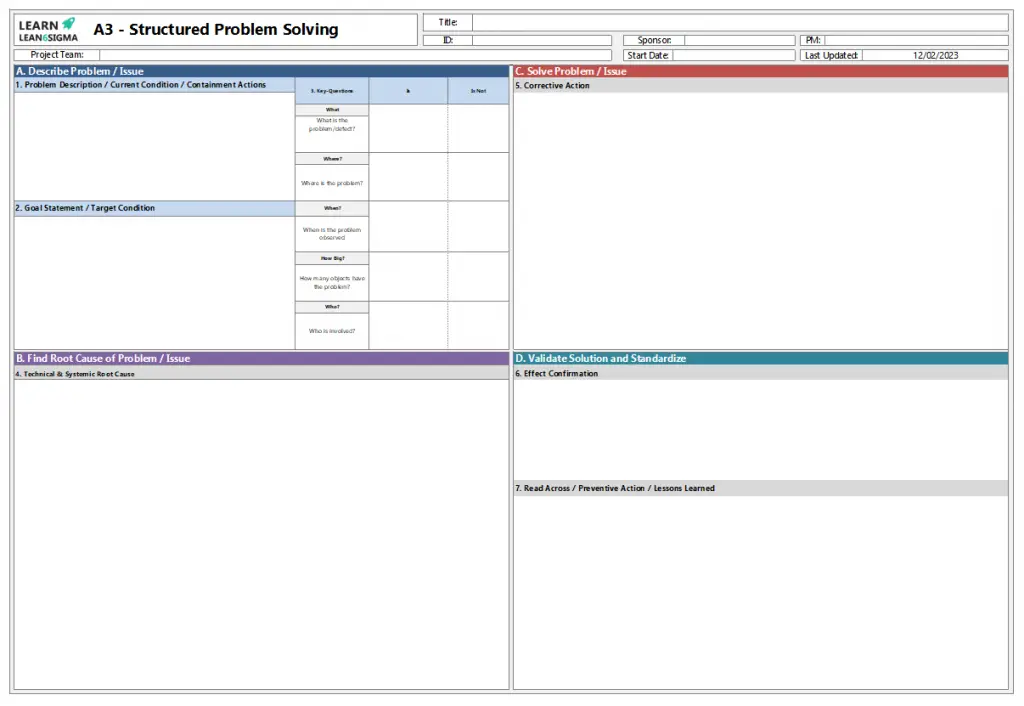

The A3 methodology is an integral part of the Toyota Production System (TPS), a set of principles and practices that have shaped the company’s approach to manufacturing, management, and continuous improvement over the years. Named after the A3 sheet of paper that was historically used to capture the plan, analysis, and follow-up on a single page, the A3 process represents a simple, yet powerful, tool for addressing complex challenges and discovering lasting solutions.

At its core, the A3 approach is rooted in three key elements:

1. Thorough problem analysis: The foundation of the A3 process lies in digging deep to diagnose the true nature and root cause of an issue, rather than jumping to hastily devised fixes that merely address symptoms.

2. Structured documentation: The A3 report serves as both a communication tool and an iterative planning device, with each section building on the previous ones to guide problem solvers through a comprehensive analysis, solution development, and execution process. It’s the foundation of good continuous improvement.

3. Cyclical learning and improvement: Leadership and employees alike are encouraged to commit to hypothesis-driven inquiry, observation, experimentation, and reflection, leading to a culture that actively seeks and leverages opportunities for growth by solving problems.

How to Implement the A3 Process in Your Organisation

The Lean Thinking A3 approach can be distilled into seven essential steps:

1. Identify the problem:

Clearly articulate and define the issue at hand, avoiding the temptation to jump to solutions or assume important facts to be self-evident..

When identifying the problem, it is important to ensure that all relevant stakeholders in the organisation are consulted. This helps to ensure that the issue is accurately described and understood from multiple perspectives. A thorough problem analysis should also include conducting research into possible causes or root issues, and clearly documenting any observed symptoms of the problem. Additionally, it is essential to identify any major risks associated with not finding a solution and recognise any constraints (both external and internal) that may exist which could limit potential solutions. Lastly, it is important to consider any potential opportunities which may arise from addressing the issue that may have been overlooked at first glance. This is the problem statement part which is a critical component that identifies the difference between the current condition and the target condition.

At this stage, we are not looking at how to solve problems being faced or at the potential solution to solving problems. It’s about developing a good understanding of how the actual results differ from the expected results and providing an in-depth systematic approach to process improvement and developing problem-solving skills.

2. Establish the context and background:

Provide a high-level overview of the problem, describing the stakeholders involved, relevant data, and the broader organisational context in which the challenge has arisen..

It is important to ensure that all stakeholders are properly considered when identifying any potential solutions as their perspectives can play a vital role in determining an effective solution. All related data should be thoroughly analysed to understand the full scope of potential solutions. This includes resources, costs, timelines, and any legal or regulatory issues that may need to be considered. Additionally, it is important to consider how well-proposed solutions fit within existing organisational policies and procedures as this could impact implementation success. Finally, understanding how proposed solutions would interact with other initiatives or processes currently taking place in the organisation can help inform decisions about whether or not they are viable options. It may include conducting some value stream mapping to dig deeper into the current state.

It is important to fully explore any underlying factors that may be contributing to the issue at hand and ensure in-depth problem analysis. This includes looking deeper into existing systems, structures, and processes related to the problem in order to identify potential areas of improvement or optimisation. Additionally, it is essential to consider any relevant industry trends or external influences that could impact how the problem manifests within the organisation.

When analysing a problem, collecting data from various sources is important to get a more comprehensive understanding of how a particular issue can be addressed. This includes mapping the current process using the VSM, SIPOC, Process Mapping or Flowcharting techniques. Additionally, interviews and surveys can be conducted with stakeholders to gain insights into how they perceive the issue and their perspectives on potential solutions. Lastly, it is important to observe any real-world activities related to the problem to uncover key areas where time, effort, resources, money etc is being wasted. This is the time improvement that may not have been identified otherwise.

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, fundamentals of lean.

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LEAN SIX SIGMA GREEN BELT

Get 3-days free access to our green belt course, accelerate your career, 3. set a goal:, now that you have identified the problem and outlined the relevant context, it is time to set a project goal or outcome..

This involves clearly articulating the desired state of affairs and any key deliverables of the proposed solution. Whether it is reducing operational costs, increasing efficiency, improving customer experience, or something else entirely – defining specific objectives with measurable metrics can help ensure that project teams stay focused and remain aligned on their ultimate destination.

At this stage, it is also important to consider how long it will take to reach the desired outcome. Establishing an implementation timeline will help safeguard progress and provide a framework for tracking results along the way. Setting milestones for achieving particular goals at certain points in time can be especially helpful in keeping teams accountable throughout the process. Additionally, having a plan for evaluating success after reaching the end target will allow stakeholders to gain further insights into how effective their approach has been in addressing underlying problems, as well as how well-proposed solutions have fared once implemented.

4. Investigate root causes:

Use a variety of techniques (e.g., the 5 whys, fishbone diagrams, pareto charts) to probe the problem’s underlying causes and avoid settling on proximate reasons..

The process of identifying root causes is essential when using data-driven tools. We always want to find the simplest root cause approach.

One of the most widely used methods for root cause analysis is the ‘5 Whys’ technique. This method involves asking a series of ‘why’ questions to determine the underlying cause of a particular symptom or issue. The goal is to keep asking “Why?” until you reach an answer that can provide insight into how to address the problem and prevent it from occurring in the future.

Another commonly used tool for root cause analysis is the fishbone diagram (also known as Ishikawa diagrams). This approach involves visualising all potential causes which could be causing a symptom or issue in a logical format, allowing users to identify patterns and uncover links between root causes and their respective effects. This technique can be helpful in identifying and focusing on key areas for improvement, as well as helping to identify interdependencies between components within an organisation’s systems.

Finally, Pareto Charts are useful for analysing data collected from surveys, interviews, observations, etc., concerning the severity or frequency of occurrence. This type of chart helps users quickly identify which factors are contributing most significantly towards an issue, allowing them to focus resources towards addressing those areas first and foremost. Additionally, Pareto charts can also be used to prioritise different solutions based on their estimated effectiveness in addressing an issue.

In conclusion, understanding the root cause of an issue through rigorous techniques such as 5 Whys, fishbone diagrams, and Pareto charts provides invaluable insight into how best to address it effectively while preventing it from reoccurring in the future. By leveraging these tools along with other data-led approaches such as process mapping and flowcharting, organisations can ensure that any proposed solutions are well-informed by both qualitative and quantitative data sources as well as ensure they are building consensus across the entire organisation.

5. Countermeasures:

Identify the right countermeasures (corrective actions) to implement that will directly impact the root causes identified..

Brainstorming is a useful tool for identifying potential improvements. It involves coming up with ideas and solutions in an open and collaborative manner, without judgement or criticism. By allowing team members to share their thoughts freely, brainstorming can help uncover innovative solutions that may have otherwise gone unnoticed. Additionally, looking at how waste reduction, flow and pull can be used to improve processes can also provide valuable insights into where improvement opportunities lie.

Brainstorm potential solutions that directly target the root causes and create detailed action plans for implementation, complete with assigned roles, responsibilities, and timelines.

Once the countermeasures are identified, it is important to design an implementation plan and assign roles & responsibilities. This will help ensure that all stakeholders understand their part in the implementation and can work together to achieve the desired outcome. Additionally, it is important to track progress along the way – setting measurable milestones that can be tracked against goals established during the initial problem-solving phase will help keep teams accountable and allow for course corrections if needed.

By utilising A3 Problem Solving Tools such as a template, organisations can easily document and share their analyses with relevant stakeholders throughout each stage of the project. Having detailed record-keeping like this also helps teams stay on target over time while providing insights into how proposed solutions may need to be re-evaluated down the line. This implementation plan provides the entire organisation with a clear project status on a one-page report.

6. Evaluate the results:

Measure the impact of your countermeasures against the problem, using well-defined success criteria, key performance indicators, or other relevant metrics..

Once the countermeasures have been implemented, it is essential to measure and evaluate their success. This can be done by tracking performance against the initial objectives established during the goal phase, as well as establishing key performance indicators to gauge how well the proposed solutions have fared.

Additionally, stakeholders should also consider conducting a post-implementation evaluation in order to assess how successful their approach has been in addressing underlying issues and determining what lessons can be learned from the experience. This will enable teams to identify strengths and weaknesses within their existing processes and make any necessary adjustments going forward. By understanding the outcomes of their improvements, organisations are able to gain valuable insights into how well they’ve succeeded in achieving their goals and ensure continued success moving forward.

Once the countermeasures have been implemented and their success measured, it is important to compare the results against the initial objective. This can be done in a variety of ways, including graphical analysis such as charts, process maps or flow diagrams. Graphical analysis helps to visualise the differences between results achieved before and after the implementation of new measures in a meaningful way. It also provides an increased level of clarity when assessing whether the desired outcomes have been achieved or not.

Process maps can be useful in understanding how changes made during the improvement phase have impacted processes within an organisation. By mapping out existing processes and then comparing them against those following implementation of countermeasures, teams can easily pinpoint where improvements were made and analyse how they led to improved performance overall.

Charts, on the other hand, enable users to quickly identify trends that may have emerged from data collected during the project. For example, if performance metrics are tracked before and after countermeasures are implemented, users can use charts and graphs to more clearly observe any patterns that may indicate an improvement or regression in performance over time – providing further insights into which areas need further attention or adjustment moving forward.

Finally, dashboard views provide an effective means of displaying results at a glance while highlighting any anomalies that might warrant further investigation. Dashboards allow stakeholders to gain access to important information quickly and easily while also helping them keep track of progress towards goals set out during initial problem-solving phases. Additionally, because dashboards support data visualisation capabilities they offer a highly interactive user experience which can help teams understand underlying trends with greater clarity and precision.

7. Standardise and share:

If a countermeasure proves successful, integrate it into the organisation’s standard operating procedures and share it with other teams as a best practice..

Once the countermeasures have been successfully implemented and measured against the initial objectives, these changes need to be integrated into the organisation’s standard operating procedures (SOPs) and shared with other teams as best practices. This will ensure that any improvements made during the problem-solving phase are consistently applied across all teams within the organisation.

In order to ensure that these improvements become part of the organisation’s long-term strategy, process maps should be updated to reflect the new improved way of working. Process maps provide a visual representation of how workflows are structured within an organisation, and by updating them in line with newly-implemented countermeasures, organisations can ensure that their processes continue to remain up-to-date and efficient moving forward. It may also be necessary to build a follow-up plan if not all tasks are fully completed as well as develop a Lean-focused PDCA cycle to ensure long-term effective collaboration on the solutions that were implemented.

Process documentation should also be updated in order to keep track of changes made during problem-solving. By documenting not just the solutions that were proposed but also why they were proposed, teams can gain valuable insights into their decision-making process which they can leverage for similar future problems.

Furthermore, it is important to update key performance indicators (KPIs) to accurately reflect any progress made during problem-solving. By tracking performance against objectives established before and after countermeasures were implemented, organisations will be able to identify any areas that may still need improvement or require further adjustment going forward. Additionally, tracking KPIs over time will help teams understand whether or not their current strategies are leading them towards meeting their goals in a timely manner or if additional measures may need to be taken in order to achieve desired results more quickly.

Finally, organisations should share successful solutions with other teams in order to promote collaboration and knowledge sharing amongst stakeholders throughout different parts of the business. This will allow for ideas generated through one team’s problem-solving efforts to benefit multiple departments – helping foster creativity and innovation while ensuring that everyone is on board with necessary changes being made throughout the organisation. The last step is key to Toyota’s PDCA management system designed for the entire organisation.

By breaking down the problem-solving process into these seven discrete stages, the A3 method offers practitioners a comprehensive, end-to-end framework for tackling complex challenges and driving improvements in any organisation.

- Lean Consultancy

- Corporate Training

Training the team on A3

To get A3 started, everyone in the entire organisation needs to learn how to use this single-sheet or single-page document. This means training people across all parts of the company so that everyone knows how to use the A3 Problem Solving Tool and A3 template. Training will help make sure that everyone follows a structured approach when using A3.

Getting the organisation fully onboard with A3 Problem Solving is not an easy task and will require a dedicated effort to ensure its successful implementation. To this end, it is important to start with specific areas of the business – whether it be operations, finance or marketing – by setting up targeted training sessions for both operational teams and senior managers. This will help everyone understand how and why A3 is used, as well as the potential benefits it can bring to their business.

Once everyone has mastered the basics of working with an A3 template, companies should look to regularly review and evaluate its effectiveness. This could include setting up quarterly reviews or running workshops where teams discuss successes and areas for improvement when using the A3 tool. Doing this will ensure that any issues are identified early on, allowing the team to quickly adjust accordingly.

At Leanscape, we understand that transitioning to A3 Problem Solving can be a daunting task. With our team of specialists, we can provide your teams with the necessary training and coaching to ensure that they are able to adapt quickly and efficiently. Our comprehensive approach to A3 will equip your team with the knowledge and skills needed to successfully use this powerful tool for improving performance in all areas of your business.

We are committed to helping you develop a culture of continuous improvement within your organisation by teaching best practices and providing guidance through every step of the problem-solving process. Through our specialised training programs, we will help your teams learn how to use the A3 template more effectively, as well as how to interpret data visualisations quickly and accurately – enabling them to take action swiftly when required. Our experienced coaches will also share insights from industry experts on how best to integrate countermeasures into standard operating procedures (SOPs) and process maps, keeping up-to-date with industry trends in order to stay ahead of the competition.

By leveraging Leanscape’s expertise in A3 Problem Solving, you can rest assured knowing that your team is in good hands. Our team is dedicated to providing you with the support needed for successful implementation so that you can achieve sustained performance improvements over time.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

The implementation of A3 Problem Solving provides a comprehensive framework for organisations looking to successfully address complex problems in an efficient and cost-effective manner. By breaking down the problem-solving process into seven distinct stages, users can structure their approach and track the progress of their countermeasures over time.

In order to ensure successful implementation, organisations should dedicate time towards training their teams on how to use the A3 Problem Solving Tool and A3 template. This will give everyone a solid foundation for carrying out future problem-solving activities more effectively, as well as provide insights into the effectiveness of certain countermeasures over time.

Through Leanscape’s specialised training programs, you can ensure that your team is fully equipped with the necessary skills to successfully adopt and incorporate A3 Problem Solving into all areas of your business. Our experienced coaches are committed to helping you develop a culture of continuous improvement within your organisation – providing guidance through every step of the process

Final Thoughts

The A3 approach is an invaluable tool for unlocking the power of improvements within any organisation. By leveraging its structured framework and cyclical learning approach, businesses can remain agile and responsive to ever-changing conditions, allowing them to navigate change more successfully and emerge stronger than ever before. Ultimately, this makes Toyota’s A3 problem-solving process one of the most effective ways to ensure long-term success in today’s fast-paced and competitive market.

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, mastering the art of lean manufacturing with an online degree, the synergy of antifragility and lean thinking, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, view all articles, green belt course, other articles, morning huddle and daily stand-up meetings | the most important business meeting, what is kanban | kanban explained for beginners, skills for leadership: 5 leadership skills from lean, how a scatter plot can upgrade your data analysis strategy, 01 – don’t kill momentum | change management | principles of lean, 5 corporate training programs every employee should take, process mapping – an essential business tool, why is kaizen important for your business to improve, unleash your business growth potential: a deep dive into the scamper brainstorming technique, understanding takt time | what is takt time, leanscape launches the online lean academy, time thieves: how time slips away.

- | lean , lean thinking , problem solving , toolkit , tools

Related Articles

Unlocking the power of the balanced scorecard: maximizing efficiency and driving growth, what is the lean six sigma green belt certification, problem solving is a must have in the workplace, here is why, what is lean six sigma, how to bring mindfulness and meditation into the workplace, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

- eNewsletter Subscription

- Operations Leadership Summit

- Great Question Podcast

- Search Search

Members Only

- Technology & IIoT

- Supply Chain

- The Economy

- Continuous Improvement

Designing a Lean Problem-Solving System with Purpose

The following is an excerpt from People Solve Problems: the Power of Every Person, Every Day, Every Problem (2021: Old Dutch Group), the latest book by IndustryWeek lean leadership contributor Jamie Flinchbaugh.

Too often, managers at all levels operate the same way during the lean journey as they did before, just with some lean lingo thrown in for good measure. They might ask someone to do an A3 and feel they are doing their part for the journey. But a manager has responsibilities in the journey that go beyond using the words and supporting the journey with resources. For starters, they must be an architect of the system of work that drives effective problem-solving.

What does it mean to be the system architect? It means that you take responsibility and ownership of the systems of work that expose problems, capture them, manage them, put resources to them and ultimately, solve them. Sending people to problem-solving training might fall into that category, but that is the easy step and far from sufficient to build an effective problem-solving organization.

Some of the key elements could, or should, be organizational standards. But someone needs to set these standards, and senior management should be highly engaged in this process. How much to standardize across an organization is worthy of some debate and depends on the organization, the existing culture, the change strategy and the level of maturity.

However, even if you adopt a strong bias toward organizational standardization, there is still much work to be done by each director or manager for their own team’s work. Standards for this work are rarely much more than guidelines, perhaps with a few IT tools thrown in. The reason for this is that all problem-solving is contextual, and you must shape your systems for the nature and content of your work.

The Landscape of Problems

We begin with what I like to call the landscape of problems. There are many sources of problems and many sources of finding those problems. Yet most teams end up deciding what problem to engage with next rather randomly, without respect to the entire landscape. Consider these many sources:

You probably have key metrics, or Key Performance Indicators, that you monitor. When properly designed, they should have a clear definition of when things are normal and when they are abnormal. When a key metric hits an abnormal level, problem solving could be initiated.

You may have standard work that helps you consistently perform your team’s tasks. However, sometimes there is a problem and the standard cannot be followed or ceases to work as designed. This condition could drive problem-solving.

You do audits of the work, ranging from a simple 5S audit to a complex customer process audit. These audits generally produce findings, each of which can be defined as a problem.

You develop a culture of identifying waste using the lens of the seven wastes and perform waste walks of the process. Each waste occurrence found is a problem that could be solved.

You fail to meet a deliverable to a customer, internal or external. You are asked what will be done about it, which means you have a problem that needs to be solved and reported back to that customer.

Your team is frustrated with something, and it is a persistent topic of conversation and drag on the team. They would like the problem fixed.

And there are more sources of problems. Here is the challenge: if each source of potential problems is managed and reacted to independently, you have no strategy for what problems you really should be solving. The simplest way to manage your landscape of problems strategically is to have a single list of problems regardless of where the problem is found, but a single list does not have to be your solution. As a leader, you must have an awareness of all the sources of problem identification and a system of work for examining and engaging with them in a balanced and purposeful way. You must have a systematic approach to managing your problem landscape. Otherwise, your team will react to each next problem that pops up in their inbox, which gives you extraordinarily little control of managing your improvement path.

The Andon, or Help Chain

A core element of your system is how you connect help to any problem as it occurs. Andon is a Japanese word meaning “lantern,” which relates to our situation as a signal light to indicate that there is a problem. If you prefer words that are more descriptive for your use, I like to call this the help chain because it is what connects help to the problem occurrence. While not every problem in your problem landscape will receive systematic problem-solving, every problem should receive attention.

To do this, you must define all of these five elements that are context-specific to the environment in which you work. First, you must define those problems that should be escalated and those that should not. For example, if your process takes five to six days, is that a problem or just natural variation of your work? More importantly, if I think you have a problem at four days and you don’t think it is a problem until you reach seven days, then in between those two markers, we are going to have plenty of frustrating tension. We should have the same definition of what is a problem.

Next, you need a way to notice the problem . This is one of the reasons that, in a lean environment, we strive to make the work as visual as possible so it is easier to detect the problem. Again, this is extremely specific to the nature of the work and must be solved at a local level.